Abstract

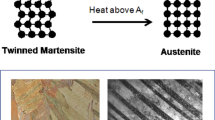

The microstructural evolution during cold rolling followed by annealing of an equiatomic NiTi shape-memory alloy was investigated. The high purity Ni50Ti50 alloy was cast by a copper boat vacuum induction-melting technique. The as-cast ingots were then homogenized, hot rolled, and annealed to prepare the suitable initial microstructure. Thereafter, annealed specimens were cold rolled up to 70 % thickness reduction at room temperature. Post-deformation annealing was conducted at 400 °C for 1 h. The microstructure was characterized using scanning electron microscopy, transmission electron microscopy, x-ray diffraction, and differential scanning calorimetry techniques. The initial microstructure was free from segregation and Ti- or Ni-rich precipitates and was composed of coarse grains with an average size of 50 μm. The cold rolling of NiTi alloy resulted in a partial amorphization and the deformation-induced grain refinement. A nanocrystalline structure with the grain size of about 20-70 nm was formed during the post-deformation annealing.

Similar content being viewed by others

References

D.C. Lagoudas, Shape Memory Alloys: Modeling and Engineering Applications, Springer, College Station, TX, 2008

K. Otsuka and C.M. Wayman, Shape Memory Materials, Cambridge University Press, Cambridge, 1998

K. Otsuka and X. Ren, Physical Metallurgy of Ti–Ni-Based Shape Memory Alloys, Prog. Mater. Sci., 2005, 50, p 511–678

K. Otsuka and X. Ren, Recent Developments in the Research of Shape Memory Alloys, Intermetallics, 1999, 7, p 511–528

J. Frenzel, Z. Zhang, K. Neuking, and G. Eggeler, High Quality Vacuum Induction Melting of Small Quantities of NiTi Shape Memory Alloys in Graphite Crucibles, J. Alloys Compd., 2004, 385, p 214–223

Z. Zhang, J. Frenzel, K. Neuking, and G. Eggeler, On the Reaction Between NiTi Melts and Crucible Graphite During Vacuum Induction Melting of NiTi Shape Memory Alloys, Acta Mater., 2005, 53, p 3971–3985

J. Frenzel, E.P. George, A. Dlouhy, Ch. Somsen, M.F.-X. Wagner, and G. Eggeler, Influence of Ni on Martensitic Phase Transformations in NiTi Shape Memory Alloys, Acta Mater., 2010, 58, p 3444–3458

Y. Kabiri, A. Kermanpur, and A. Foroozmehr, Comparative Study on Microstructure and Homogeneity of NiTi Shape Memory Alloy Produced by Copper Boat Induction Melting and Conventional Vacuum Arc Melting, Vacuum, 2012, 86, p 1073–1077

S.D. Prokoshkin, V. Brailovski, K.E. Inaekyan, V. Demers, Y.I. Khmelevskaya, S.V. Dobatkin, and E.V. Tatyanin, Structure and Properties of Severely Cold-Rolled and Annealed Ti–Ni Shape Memory Alloys, Mater. Sci. Eng. A, 2008, 481–482, p 114–118

K. Tsuchiya, M. Inuzuka, D. Tomus, A. Hosokawa, H. Nakayama, K. Morii, Y. Todaka, and M. Umemoto, Martensitic Transformation in Nanostructured TiNi Shape Memory Alloy Formed Via Severe Plastic Deformation, Mater. Sci. Eng. A, 2006, 438–440, p 643–648

A. Foroozmehr, A. Kermanpur, F. Ashrafizadeh, and Y. Kabiri, Effects of Thermo-Mechanical Parameters on Microstructure and Mechanical Properties of Ti–50 at.%Ni Shape Memory Alloy Produced by VAR Method, Mater. Sci. Eng. A, 2012, 535, p 164–169

H.C. Lin and S.K. Wu, Determination of Heat Of Transformation in a Cold-Rolled Martensitic TiNi Alloy, Metall. Mater. Trans. A, 1993, 24, p 293–299

S.H. Chang, S.K. Wu, and G.H. Chang, Transformation Sequence in Severely Cold-Rolled and Annealed Ti50Ni50 Alloy, Mater. Sci. Eng. A, 2006, 438–440, p 509–512

V.G. Pushin, V.V. Stolyarov, R.Z. Valiev, T.C. Lowe, and Y.T. Zhu, Nanostructured TiNi-Based Shape Memory Alloys Processed by Severe Plastic Deformation, Mater. Sci. Eng. A, 2005, 410–411, p 386–389

S.H. Chang and S.K. Wu, Effect of Cooling Rate on Transformation Temperature Measurements of Ti50Ni50 Alloy by Differential Scanning Calorimetry and Dynamic Mechanical Analysis, Mater. Charact., 2008, 59, p 987–990

J. Koike, D.M. Parkin, and M. Nastasi, Crystal-to-Amorphous Transformation of NiTi Induced by Cold Rolling, J. Mater. Res., 1990, 7, p 1414–1418

T. Waitz, V. Kazykhanov, and H.P. Karnthaler, Martensitic Phase Transformations in Nanocrystalline NiTi Studied by TEM, Acta Mater., 2004, 52, p 137–147

A.V. Sergueeva, C. Song, R.Z. Valiev, and A.K. Mukherjee, Structure and Properties of Amorphous and Nanocrystalline NiTi Prepared by Severe Plastic Deformation and Annealing, Mater. Sci. Eng. A, 2003, 339, p 159–165

S. Jiang, L. Hu, Y. Zhao, Y. Zhang, and Y. Liang, Multiscale Investigation of Inhomogeneous Plastic Deformation of NiTi Shape Memory Alloy Based on Local Canning Compression, Mater. Sci. Eng. A, 2013, 569, p 117–123

K.H.J. Buschow, Stability and Electrical Transport Properties of Amorphous Ti1−x Ni x Alloys, J. Phys. F: Met. Phys, 1983, 13, p 563–571

Acknowledgments

The authors would like to sincerely acknowledge the financial support of Iran National Science Foundation (Contact No. 89001410).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohammad Sharifi, E., Kermanpur, A., Karimzadeh, F. et al. Formation of the Nanocrystalline Structure in an Equiatomic NiTi Shape-Memory Alloy by Thermomechanical Processing. J. of Materi Eng and Perform 23, 1408–1414 (2014). https://doi.org/10.1007/s11665-013-0856-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0856-9