Abstract

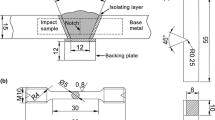

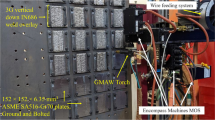

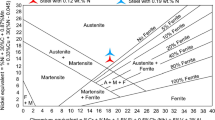

The weld overlay of Alloy 52M (a nickel-based filler metal) on a cast 304 (CF8) stainless steel (SS) was made to simulate overlay welding of the safe end of reactor pressure vessels in nuclear power plants. The deteriorated effect of sulfur on solidification cracking of the Alloy 52M overlay was highlighted by using a CF8 substrate with 0.14 wt.% S. Severe solidification cracking was observed when Alloy 52M was directly overlaid on the CF8 substrate. To lower the cracking susceptibility, ER 308L was deposited on the CF8 SS as a buffer layer before the subsequent deposition of Alloy 52M. Under such circumstances, the region near the weld interface between the SS buffer layer and Alloy 52M overlay was susceptible to solidification cracking. The formation of γ-NbC(N), γ-Laves, and γ-(Fe-Ni-S) eutectic-type constituents at the solidification boundaries was responsible for cracking near the weld interface. Nevertheless, depositing two layers of 308L prior to applying Alloy 52M could effectively reduce the cracking susceptibility of the overlay.

Similar content being viewed by others

References

N. Suutala, T. Takalo, and T. Moisio, The Relationship Between Solidification and Microstructure in Austenitic and Austenitic-Ferritic Stainless Steel Welds, Metall. Trans., 1979, 10A, p 512–514

N. Suutala, T. Takalo, and T. Moisio, Ferritic-Austenitic Solidification Mode in Austenitic Stainless Steel Welds, Metall. Trans., 1980, 11A, p 717–725

G. Srinivasan, A.K. Bhaduri, V. Shankar, and B. Raj, Evaluation of Hot Cracking Susceptibility of Some Austenitic Stainless Steels and a Nickel-Base Alloy, Weld. World, 2008, 52, p 4–17

B.T. Alexandrov, A.T. Hope, J.W. Sowards, J.C. Lippold, and S.S. McCracken, Weldability Studies of High-Cr, Ni-Base Filler Metals for Power Generation Applications, Weld. World, 2011, 55, p 65–76

J.A. Brooks, A.W. Thompson, and J.C. Williams, A Fundamental Study of the Beneficial Effects of Delta Ferrite in Reducing Weld Cracking, Weld. J., 1984, 63, p 71–83

V. Kujanpää, N. Suutala, T. Takalo, and T. Moisio, Correlation Between Solidification Cracking and Microstructure in Austenitic and Austenitic-Ferritic Stainless Steel, Weld. Res. Int., 1979, 9, p 55–76

J.A. Brooks and F.J.J. Lambert, The Effects of Phosphorus Sulfur and Ferrite Content on Weld Cracking of Type 309 Stainless Steel, Weld. J., 1978, 57, p 139–143

G.M. Goodwin, The Effects of Heat Input and Weld Process on Cracking in Stainless Steel, Weld. J., 1988, 67, p 88–94

H.K.D.H. Bhadeshia, S.A. David, and J.M. Vitek, Solidification Sequences in Stainless Steel Dissimilar Alloy Welds, Mater. Sci. Technol. Lond., 1991, 7, p 50–61

R.A. Patterson and J.O. Milewski, GTA Weld Cracking Alloy 625 to 304L, Weld. J., 1985, 64, p 227–231

K. Shinozaki, M. Yamamoto, A. Kawasaki, T. Tamura, and P. Wen, Development of Evaluation Method for Solidification Cracking Susceptibility of Inconel600/SUS347 Dissimilar Laser Weld Metal by In-Situ Observation, Mater. Sci. Forum, 2008, 580-582, p 49–52

MRP-106. Materials Reliability Program (MRP-106): Welding Residual and Operating Stresses in PWR Alloy 182 Butt Welds, EPRI Report 1009378, Palo Alto, CA, USA, 2004

MRP-169. Materials Reliability Program (MRP-169): Technical Basis for Preemptive Weld Overlays for Alloy 82/182 Butt Welds in PWRs, EPRI Report 1012843, Palo Alto, CA, USA, 2005

T.K. Song, H.R. Bae, Y.J. Kim, and K.S. Lee, Numerical Investigation on Welding Residual Stresses in a PWR Pressurizer Safety/Relief Nozzle, Fatigue Fract. Eng. Mater., 2010, 33, p 689–702

C.-C. Huang and R.-F. Liu, Structural Integrity Analyses for Preemptive Weld Overlay on the Dissimilar Metal Weld of a Pressurizer Nozzle, Int. J. Press. Vessels Pip., 2012, 90-91, p 77–83

N.G. Cofie, R.E. Smith, R.L. Bax, C.S. Lohse, B. Hermanns, J. Valsvig, L.D. Yepez, and D. Parker, Effectiveness of Stainless Steel Buffer Layer to Address Hot Cracking During Weld Overlay Repair of Dissimilar Metal Alloy 82/182 Welds with Stainless Steel Piping, ASME Conference Proceedings, 2008, p 43–52

H.A. Chu, M.C. Young, H.C. Chu, L.W. Tsay, and C. Chen, Hot Cracking Susceptibility of ALLOY 52M Weld Overlays onto CF8 Stainless Steel, J. Nucl. Mater., 2013, 433, p 419–423

J.N. DuPont, Solidification of an Alloy 625 Weld Overlay, Metall. Mater. Trans. A, 1996, 27, p 3612–3620

J.N. DuPont, M.R. Notis, A.R. Marder, C.V. Robino, and J.R. Michael, Solidification of Nb-Bearing Superalloys: Part I. Reaction Sequences, Metall. Mater. Trans. A, 1998, 29, p 2785–2796

J.N. DuPont and C.V. Robino, The Influence of Nb and C on the Solidification Microstructures of Fe-Ni-Cr Alloys, Scr. Mater., 1999, 41, p 449–454

S.L. McCracken and R.E. Smith, Behavior and Hot Cracking Susceptibility of Filler Metal (ERNICrFe-7A) Overlays on Cast Austenitic Stainless Steel Base Materials, Hot Cracking Phenomena in Welds III, J. Lippold, Ed., Springer, Dordrecht, 2011, p 333–352

Acknowledgments

The authors gratefully acknowledge financial support of this study by the Institute of Nuclear Energy Research, Division of Nuclear Fuels and Materials, Taiwan, Republic of China (Contract No. NL0990178).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chu, H.A., Young, M.C., Chu, H.C. et al. The Effect of Nb and S Segregation on the Solidification Cracking of Alloy 52M Weld Overlay on CF8 Stainless Steel. J. of Materi Eng and Perform 23, 967–974 (2014). https://doi.org/10.1007/s11665-013-0812-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0812-8