Abstract

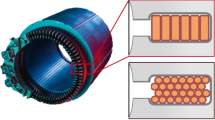

The paper presents how the “Dynamic Quenching” and “Reversing gas flow” processes are successfully applied on internal ring gears and planetary gears for a 6-speed automatic transmission. The specific challenge was to reduce distortion in such a way that subsequent machining operations are entirely eliminated. As a result of extensive development in the quenching process, it was possible to meet the design metrological requirements. The internal ring gears have been in continuous production since 2006. By utilizing the special CFC fixtures and quench methodology of “Dynamic Quenching,” the customer was able to achieve the design intent, while eliminating all machining operations of the ring gears following LPC/HPGQ. Subsequent testing and monitoring over a 2-year period progressively demonstrated that conformance. Therefore, quality inspection was reduced accordingly.

Similar content being viewed by others

References

K. Heeß, Maß- und Formänderungen infolge Wärmebehandlung von Stählen. Expert Verlag. 3. neu bearbeitete Auflage, 2007, ISBN-10: 3-8169-2678-9

H. Walton, Dimensional Changes during Hardening and Tempering of Through-Hardened Bearing Steels, Quenching and Distortion Control (Conference Proceedings), ASM International, 1992, p S. 265–S. 273

A. Stich and H.M. Tensi, HTM 50, 1995

H. Altena, F. Schrank, und W. Jasienski, Reduzierung der Formänderung von Getriebeteilen in Gasaufkohlungs-Durchstoßanlagen durch Hochdruck-Gasabschreckung, HTM 60, Vol. 1, 2005, p S. 43–S. 50

V. Heuer and K. Loeser, Low pressure carburizing for transmissions. In: Gear solutions July 2009

K. Loeser, G. Stueber, G. Welzig, and V. Heuer, United States Patent No. US 6,913,449 B2, Apparatus for the Treatment of Metallic Workpieces with Cooling Gas, 5 July 2005, Stich, Tensi, HTM 50, 1995

V. Heuer and K. Löser, Entwicklung des dynamischen Abschreckens in Hochdruck-Gasabschreckanlagen. Mat.-wiss. u. Werkstofftech., 2003, 34, p 56–63

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 26th ASM Heat Treating Society Conference, held October 31 through November 2, 2011, in Cincinnati, Ohio, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Heuer, V., Faron, D.R., Bolton, D. et al. Distortion Control of Transmission Components by Optimized High Pressure Gas Quenching. J. of Materi Eng and Perform 22, 1833–1838 (2013). https://doi.org/10.1007/s11665-013-0547-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-013-0547-6