Abstract

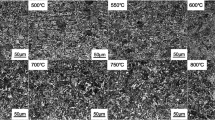

Hot forming of ultra high strength steel (UHSS) sheet metal grade 22MnB5 boron for channel components using water cooling is studied on a laboratory scale. After hot forming, the different microstructures such as martensite, bainite, and pearlite in formed component are produced, which are closely related with mechanical properties of formed component. The effect of forming start temperature and the contact state between blank and die on the microstructure evolution is investigated. In addition, the effect of processing parameters, such as forming start temperature and blank holder force (BHF), on the final quality of component, i.e., springback, that happens after hot forming of UHSS is investigated. It can be concluded that the forming start temperature has a significant effect on the final mechanical properties of formed components. The effect of forming start temperature on springback is examined in detail under a wide range of operating conditions. The higher the BHF and the forming start temperature, the lower is the springback after hot forming. Furthermore, thermo-mechanically coupled finite element analysis model encompassing heating of sheet blank, forming and quenching are developed for hot forming process. The stress distributions on sheet blank under different conditions during hot forming are compared to gain a fundamental understanding of the mechanism of springback. Comparisons show that numerical simulation results have good agreement with experimental results.

Similar content being viewed by others

References

L. Vaissiere, J.P. Laurent, and A. Reihardt, Development of Pre-Coated Boron Steel for Applications on PSA Peugeot Citroen and RENAULT Bodies in White, J. Mater. Process. Technol., 2003, 111, p 909–917

R. Kolleck, D. Steinhoefer, J.A. Feindt, and P. Bruneau, Manufacturing Methods for Safety and Structural Body Components for Lightweight Body Design, IDDRG, Conf. Proc., 2004, p 167–173

L. Garcia Aranda, P. Ravier, and Y. Chstel, Hot Stamping of Quenchable Steels, Material Data and Process Simulations, IDDRG, Conf. Proc., 2003, p 155–164

L. Gehringhoff, High Strength Hot Stamped Parts for Body Structures, New Advances in Body Engineering, Euromotor Course, IKA RWTH Aachen, 2004, p 1–15

M. Merklein, C. Hoff, and J. Lechler, Einflussgr¨oßen im Pressh¨artprozess, Tagungsband 4, Chemnitzer Karosseriekolloquium, Chemnitz, Germany, 2005, p 137–153

M. Geiger, M. Merklein, and C. Hoff, Basic Investigations on the Hot Stamping Steel 22MnB5, Adv. Mater. Res., 2005, (6–8), p 795–804

S. Chatterjee, H.S. Wang, J.R. Yang, and H.K.D.H. Bhadeshia, Mechanical Stabilisation of Austenite, Mater. Sci. Technol., 2006, 22(6), p 641–644

M. Naderi and W. Bleck, Martensitic Transformation during. Simultaneous High Temperature Forming and Cooling Experiments, Steel Res. Int., 2007, 78(12), p 914–920

R. Neugebauer, T. Altan, T. Geiger, M. Kleiner, and A. Sterzing, Sheet Metal Forming at Elevated Temperature, Ann. CIRP., 2006, 55(2), p 793–816

F. Vollertsen and K. Lange, Enhancement of Drawability by Local Heat Treatment, Ann. CIRP., 1998, 47(1), p 181–184

M. Merklein and J. Lechler, Investigation of the Thermo-mechanical Properties of Hot Stamping Steels, J. Mater. Process. Technol., 2006, 177, p 452–455

B. Shapiro, Using Ls-Dyna to Model Hot Sheet Metal Forming, First International Conference on Hot Sheet Metal Forming of High-Performance Steel, Kassel, Germany, 2008

M. Eriksson, M. Oldenburg, M.C. Somani, and L.P. Karjalainen, Testing and Evaluation of Material Data for Analysis of Forming and Hardening of Boron Steel Components, Modell. Simul. Mater. Sci. Eng., 2002, 10, p 1–18

W.H. McAdams, Heat Transmission, 3rd ed., McGraw Hill, New York, 1954, p 180

L. Sellers, Proc. of 2nd Int. Conf. Modeling of Metals Rolling Processes, The Institute of Materials, London, 1996

R.D. Pehlke, A. Jeyarajan, and H. Wada, Summary of Thermal Properties for Casting Alloys and Mold Materials, University of Michigan, Ann Arbor, MI, 1982

M. Naderia, L. Durrenberger, A. Molinarib, and W. Blecka, Constitutive Relationships for 22MnB5 Boron Steel Deformed Isothermally at HighTemperatures, Mater. Sci. Eng. A, 2008, 478, p 130–139

M.G. Lee, D. Kim, C. Kim, M.L. Wenner, and K. Chung, Spring-back Evaluation of Automotive Sheets Based on Isotropic-kinematic Hardening Laws and Non-quadratic Anisotropic Yield Functions. Part III. Applications, Int. J. Plast., 2005, 21, p 915–953

Acknowledgments

This work is made possible by supports from natural science foundation of Heilongjiang Province China under Grant No. QC07C07 and China Postdoctoral Science Foundation under Grant No. 20080440846.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, H., Liu, W., Bao, J. et al. Numerical and Experimental Investigation into Hot Forming of Ultra High Strength Steel Sheet. J. of Materi Eng and Perform 20, 1–10 (2011). https://doi.org/10.1007/s11665-010-9641-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-010-9641-1