Abstract

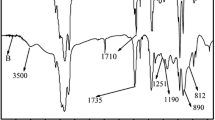

The modification of epoxy (EP) resin with carboxyl-terminated polybutadiene (CTPB) liquid rubber was carried out in this work. The chemical reaction between the oxirane ring of EP and the carboxyl group of CTPB and kinetic parameters were investigated by Fourier transform infrared and differential scanning calorimetry. The resulting pre-polymers were cured with methyl hexahydrophthalic anhydride. Scanning electron microscopic observations indicate that the micro-sized CTPB particles dispersed uniformly in the EP matrix formed a two-phase morphology, mainly contributing to the improved toughness of the modified network. The best overall mechanical performance was achieved with 20 phr CTPB; above it, a fall in the strength and modulus was observed. The storage modulus and loss declined with the CTPB concentration due to its lower modulus and plasticizing effect from dynamic mechanical analysis measurements. Moreover, due to the weak polarity and excellent electrical insulation of CTPB, the CTPB-modified EP presented higher electrical resistivities and breakdown strength, and low dielectric permittivity and loss compared with neat EP.

Similar content being viewed by others

References

K. Huang, Y. Zhang, M. Li, J. Lian, X. Yang, and J. Xia, Prog. Org. Coat. 74, 240 (2012).

W. Jilani, N. Mzabi, O. Gallot-Lavall’ee, F. Najla, Z. Chouki, Z. Rachida, and G. Hajer, Eur. Phys. J. Plus 130, 76 (2015).

B.G. Soares, K. Dahmouche, V.D. Lima, A.A. Silva, S.P.C. Caplan, and F.L. Barcia, J. Colloid Interface Sci. 358, 338 (2011).

N. Chikhi, S. Fellahi, and M. Bakar, Eur. Polym. J. 38, 251 (2002).

M.R. Dadfar and F. Ghadami, Mater. Des. 47, 16 (2013).

K. Zhao, J. Wang, X.X. Song, C.S. Liang, and S.A. Xu, Thermochim. Acta 605, 8 (2015).

H. Zhou and S. Xu, Mater. Lett. 121, 238 (2014).

T. Raju, Y.M. Ding, and Y.L. He, Polymer 49, 278 (2008).

H.H. Wang and J.C. Chen, Eng. Sci. 35, 1468 (1995).

M.F. Zeng, X.D. Sun, and H.Q. Xiao, Radiat. Phys. Chem. 77, 245 (2008).

S.B. Chen, Q.H. Wang, and T.M. Wang, Polym. Test. 30, 726 (2011).

B. Wetzel, P. Rosso, F. Haupert, and K. Friedrich, Eng. Fract. Mech. 73, 2375 (2006).

W.Y. Zhou and D.M. Yu, J. Appl. Polym. Sci. 118, 3156 (2010).

W.Y. Zhou and J.T. Cai, J. Appl. Polym. Sci. 124, 4346 (2012).

A. Devi and D. Srivastava, Mater. Sci. Eng. A 458, 336 (2007).

D. Roşu, C.N. Caşcaval, F. Mustata, and C. Ciobanu, Thermochim. Acta 383, 119 (2002).

W. Liu, Q. Qiu, J. Wang, Z. Huo, and H. Sun, Polymer 49, 4399 (2008).

S. Khoee, A.R. Mahdavian, W. Bairamy, and M. Ashjari, J. Colloid Interface Sci. 336, 872 (2009).

R. Akbari, M.H. Beheshty, and M. Shervin, Iran. Polym. J. 22, 313 (2013).

R. Yadav and D. Srivastava, Int. J. Plast Technol. 18, 27 (2014).

W.Y. Zhou and J. Zuo, J. Reinf. Plast. Comp. 32, 1359 (2013).

G. Tripathi and D. Srivastava, Mater. Sci. Eng. A 496, 483 (2008).

A. Devi and D. Srivastava, Eur. Polym. J. 43, 2422 (2007).

K. Zhao, X.X. Song, J. Wang, C.S. Liang, and S.A. Xu, Iran. Polym. J. 24, 425 (2015).

Q. Ren, Y. Xiang, C.Y. Huang, J. Li, and C.Y. Wang, Polym. Bull. 72, 2949 (2015).

T. Garima and S. Deepak, Mater. Sci. Eng. A 443, 262 (2007).

V. Nigam, D.K. Setua, and G.N. Mathur, J. Therm. Anal. Calorim. 64, 521 (2001).

H.J. Sue, P.M. Puckett, J.L. Bertram, L.L. Walker, and E.I. Garcia-Meitin, J. Polym. Sci. Polym. Phys. 37, 2137 (1999).

W.Y. Zhou and D. Yu, J. Appl. Polym. Sci. 112, 1695 (2009).

C. Wang, F.F. Ma, H. Li, and J. Wang, in 2014 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), IEEE (2014), pp. 836–839

Acknowledgement

The authors gratefully acknowledge financial support from the National Science Foundation of China (Nos. 51577154, 51073180), the Key Laboratory of Engineering Dielectrics and Its Application, Ministry of Education, Harbin University of Science and Technology (JZK201301), the Scientific Research Program Funded by Shaanxi Provincial Education Commission (Program No. 14JK1485), and the Foundation for Key Program of Ministry of Education, China (212175).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Dong, L., Zhou, W., Sui, X. et al. A Carboxyl-Terminated Polybutadiene Liquid Rubber Modified Epoxy Resin with Enhanced Toughness and Excellent Electrical Properties. J. Electron. Mater. 45, 3776–3785 (2016). https://doi.org/10.1007/s11664-016-4495-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-016-4495-4