Abstract

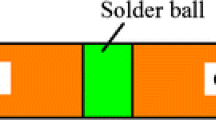

The growth behavior of interfacial intermetallic compounds (IMCs) of SnAgCu/Cu soldered joints was investigated during the reflow process, isothermal aging, and thermal cycling with a focus on the influence of these parameters on growth kinetics. The SnAgCu/Cu soldered joints were isothermally aged at 125°C, 150°C, and 175°C while the thermal cycling was performed within the temperature ranges from −25°C to 125°C and −40°C to 125°C. It was observed that a Cu6Sn5 layer formed, followed by rapid coarsening at the solder/Cu interface during reflowing. The grain size of the interfacial Cu6Sn5 was found to increase with aging time, and the morphology evolved from scallop-like to needle-like to rod-like and finally to particles. The rod-like Ag3Sn phase was formed on the solder side in front of the previously formed Cu6Sn5 layer. However, when subject to an increase of the aging time, the Cu3Sn phase was formed at the interface of the Cu6Sn5 layer and Cu substrate. The IMC growth rate increased with aging temperature for isothermally aged joints. During thermal cycling, the thickness of the IMC layer was found to increase with the number of thermal cycles, although the growth rate was slower than that for isothermal aging. The dwell time at the high-temperature end of the thermal cycles was found to significantly influence the growth rate of the IMCs. The growth of the IMCs, for both isothermal aging and thermal cycling, was found to be Arrhenius with aging temperature, and the corresponding diffusion factor and activation energy were obtained by data fitting. The tensile strength of the soldered joints decreased with increasing aging time. Consequently, the fracture site of the soldered joints migrated from the solder matrix to the interfacial Cu6Sn5 layer. Finally, the shear strength of the joints was found to decrease with both an increase in the number of thermal cycles and a decrease in the dwell temperature at the low end of the thermal cycle.

Similar content being viewed by others

References

Y.G. Lee and J.G. Duh, J. Mater. Sci. Mater. Electron. 10, 33 (1999).

X.Y. Li and Z.S. Wang, J. Mater. Process. Technol. 183, 6 (2007).

L.H. Xu, J.H.L. Pang, K.H. Prakash, and T.H. Low, IEEE Trans. Comp. Pack. Technol. 28, 408 (2005).

L.P. Lehman, R.K. Kinyanjui, J. Wang, Y. Xing, L. Zavalij, P. Borgesen, and E.J. Cotts, Electronic Components and Technology Conference (May 31–June 3, 2005), pp. 674–681.

J.H. Lee, J.H. Park, Y.H. Lee, Y.S. Kim, and D.H. Shin, J. Mater. Res. 16, 1227 (2001).

K. Zeng and K.N. Tu, Mater. Sci. Eng. R. 38, 55 (2002).

J.K. Chen, J.E. Beraun, and D.Y. Tzou, J. Mater. Sci. 34, 6183 (1999).

X.Y. Li, X.H. Yang, and F.H. Li, International Conference on Electronic Packaging Technology and High Density Packaging (ICEPT-HDP, July 28–31, 2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, X., Li, F., Guo, F. et al. Effect of Isothermal Aging and Thermal Cycling on Interfacial IMC Growth and Fracture Behavior of SnAgCu/Cu Joints. J. Electron. Mater. 40, 51–61 (2011). https://doi.org/10.1007/s11664-010-1401-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-010-1401-3