Abstract

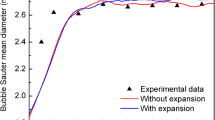

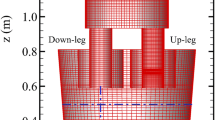

In an industrial Ruhrstahl–Heraeus (RH) degasser, gas bubbles can expand rapidly due to heating by the melt as well as to the significant pressure drop when they rise in the melt. A suitable model for the bubble expansion is, therefore, essential for the accurate numerical prediction of argon–melt hydrodynamics in an RH degasser. This study focuses on the evaluation and comparison of different bubble expansion models available in the literature based on a coupled computational fluid dynamics–population balance model. The simulation results show that compared with the measured results, the modified Szekely–Martins model demonstrates the suitability for treating the bubble expansion behavior and thereby simulating the argon–melt hydrodynamics in an industrial RH degasser. The flow field and bubble expansion, breakup, and coalescence phenomena are then investigated.

Similar content being viewed by others

Abbreviations

- A g :

-

Surface area of an Ar bubble (m2)

- \( \overrightarrow {A} _{i} \) :

-

Area vectors of face i (m2)

- \(B_{i}^{{{\text{Coa}}}}\),\(B_{i}^{{{\text{Bre}}}}\) :

-

Birth rates (1/(m3 s))

- c kj :

-

Coalescence rate (m3/s)

- C g :

-

Heat capacity (J/(kg K))

- C D, C L, C VM :

-

Drag, lift, and virtual mass coefficients

- C μ, C 1 ε, C 2 ε, C 3 ε :

-

Constants

- d 32 :

-

Sauter mean diameter (m)

- d i :

-

Diameter of bubble with size i (m)

- \(D_{i}^{{\text{Coa}}}\),\(D_{i}^{{\text{Bre}}}\) :

-

Death rates (1/(m3 s) )

- \(\vec{F}_{\text{D}}\),\(\vec{F}_{\text{L}}\),\(\vec{F}_{{\text{TD}}}\),\(\vec{F}_{{\text{VM}}}\) :

-

Drag, lift, turbulent dispersion, and virtual mass forces (N/m3)

- \(\vec{g}\) :

-

Gravitational acceleration (m/s2)

- G k,l :

-

Production of melt turbulent kinetic energy (m2/s3)

- h g :

-

Heat transfer coefficient (J/(m2 s K))

- k l :

-

Melt turbulent kinetic energy (m2/s2)

- M g :

-

Argon molecular weight (kg/mol)

- n i, n k, n j :

-

Bubble number concentration (1/m3)

- p g :

-

Bubble pressure (N/m2)

- P 0 :

-

Pressure at the nozzle exits (N/m2)

- r g :

-

Bubble diameter (m)

- R:

-

Gas constant (J/(mol·K))

- Re:

-

Reynolds number

- t :

-

Bubble rising time (s)

- T :

-

Temperature (K)

- \(\vec{u}_{\text{g}}\),\(\vec{u}_{\text{l}}\) :

-

Velocity of argon, and melt (m/s)

- u slip :

-

Slip velocity (m/s)

- V i :

-

Volume of a bubble with size i (m3)

- α g, α l :

-

Volume fraction

- ε l :

-

Melt turbulent kinetic energy dissipation rate (m2/s3)

- λ g :

-

Heat conductivity coefficient (J/(m s K))

- μ l, μ t :

-

Melt molecular viscosity and turbulent viscosity (kg/(m s))

- ρ g, ρ l :

-

Density of argon and melt (kg/m3)

- σ l :

-

Surface tension (N/m)

- σ k, σ ε :

-

Constants

- Ω i :

-

Breakup frequency (1/s)

- χ jk :

-

Bubble redistribution coefficient

- g :

-

Argon

- l :

-

Melt

- 0:

-

At the injection location

References

A.N. Conejo, R. Mishra, and D. Mazumdar: Metall. Mater. Trans. B., 2019, vol. 50(3), pp. 1490–1502.

S.W.P. Cloete, J.J. Eksteen, and S.M. Bradshaw: Miner Eng., 2013, vol. 46–47, pp. 16–24.

P.K. Singh and D. Mazumdar: Metall. Mater. Trans. B., 2019, vol. 50(2), pp. 1091–1103.

B.C. Han, G.S. Wei, R. Zhu, W.H. Wu, J.J. Jiang, C. Feng, J.F. Dong, S.Y. Hu, and R.Z. Liu: J. CO2 Util., 2019, vol. 34, pp. 53–62.

S. Chatterjee, D.H. Li, and K. Chattopadhyay: Metall Mater. Trans. B., 2018, vol. 49(2), pp. 756–766.

J.R.S. de Rocha, E.E.B. de Souza, F. Marcondes, and J.A. de Castro: J. Mater. Res. Technol., 2019, vol. 8(5), pp. 4209–20.

S.H. Majidi, J. Griffin, and C. Beckermann: Metall Mater. Trans. B., 2018, vol. 49(5), pp. 2599–610.

C.A. Real-Ramirez, I. Carvajal-Mariscal, F. Sanchez-Silva, F. Cervantes-De-La-Torre, J. Diaz-Montes, and J. Gonzalez-Trejo: Metall Mater. Trans. B., 2018, vol. 49(4), pp. 1644–57.

A.P.R. da Santos, T.C. da Mota, H.V.G. Segundo, L.H. de Almeida, L.S. Araújo, and A.C. da Rocha: J. Mater. Res. Technol., 2018, vol. 7(3), pp. 331–6.

Y.G. Park, W.C. Doo, K.W. Yi, and S.B. An: ISIJ Int., 2000, vol. 40(8), pp. 749–55.

Y.G. Park and K.W. Yi: ISIJ Int., 2003, vol. 43(9), pp. 1403–9.

M.Y. Zhu, Y.L. Wu, C.W. Du, and Z.Z. Huang: J. Iron Steel Res. Int., 2005, vol. 12(2), pp. 20–4.

D.Q. Geng, H. Lei, and J.C. He: Metall Mater. Trans. B., 2010, vol. 41(1), pp. 234–47.

D.Q. Geng, H. Lei, and J.C. He: Ironmak. Steelmak., 2012, vol. 39(6), pp. 431–38.

H.T. Ling, F. Li, L.F. Zhang, and A. Conejo: Metall Mater. Trans. B., 2016, vol. 47(3), pp. 1950–61.

H.T. Ling, L.F. Zhang, and C. Liu: Ironmak. Steelmak., 2018, vol. 45(2), pp. 145–56.

H.T. Ling and L.F. Zhang: Metall Mater. Trans. B., 2018, vol. 49(5), pp. 2709–21.

G.J. Chen, S.P. He, and Y.G. Li: Metall Mater. Trans. B., 2017, vol. 48(4), pp. 2176–86.

Y. Luo, C. Liu, Y. Ren, and L.F. Zhang: Steel Res. Int., 2018, vol. 89(12), p. 1800048.

P.A. Kishan and S.K. Dash: Int. J. Numer. Methods Heat Fluid Flow., 2006, vol. 16(8), pp. 890–909.

D.Q. Geng, J. Zheng, K. Wang, P. Wang, R. Liang, H. Liu, H. Lei, and J.C. He: Metall. Mater. Trans. B., 2015, vol. 46(3), pp. 1484–93.

J.H. Wei and H.T. Hu: Ironmak. Steelmak., 2005, vol. 32(5), pp. 427–34.

J.H. Wei and H.T. Hu: Steel Res Int., 2006, vol. 77(1), pp. 32–6.

J.M. Zhang, L. Liu, X.Y. Zhao, S.W. Lei, and Q.P. Dong: ISIJ Int., 2014, vol. 54(7), pp. 1560–9.

B.H. Zhu, Q.C. Liu, M. Kong, J. Yang, D. Li, and K. Chattopadhyay: Metall Mater. Trans. B., 2017, vol. 48(5), pp. 2620–30.

J. Peixoto, W. Gabriel, T. de Oliveira, C. da Silv, I. da Silva, and V. Seshadri: Metall Mater. Trans. B., 2018, vol. 49(5), pp. 2421–34.

S. Chen, H. Lei, M. Wang, B. Yang, L. Dai, and Y. Zhao: Vacuum., 2019, vol. 167, pp. 255–62.

G.J. Chen, S.P. He, Y.G. Li, Y.T. Guo, and Q. Wang: JOM., 2016, vol. 68(8), pp. 2138–48.

P.A. Kishan and S.K. Dash: ISIJ Int., 2009, vol. 49(4), pp. 495–504.

L. Li, Z. Liu, B. Li, H. Matsuura, and F. Tsukihashi: ISIJ Int., 2015, vol. 55(7), pp. 1337–46.

G.J. Chen and S.P. He: J. Mater. Sci. Technol., 2020, vol. 9(3), pp. 3318–29.

Z.Q. Liu, F.S. Qi, B.K. Li, and S.C.P. Cheung: Int. J. Multiphas. Flow., 2016, vol. 79, pp. 190–201.

J. Szekely and G.P. Martins: Trans. Met. Soc. AIME., 1969, vol. 245, pp. 629–36.

V.G. Levich: Physicochemical Hydrodynamics, Prentice-Hall Inc., Englewood Cliffs, 1962, p. 452.

P.V. Danckwerts: Gas-Liquid Reactions, McGraw-Hill Book Company, Great Britain, 1970.

S.V. Komarov and M. Sano: ISIJ Int., 1998, vol. 38(10), pp. 1045–52.

M. Sano, K. Mori, and Y. Fujita: Tetsu-to-Hagané., 1979, vol. 65(8), pp. 1140–8.

K. Mori, M. Sano, and T. Sato: Trans ISIJ., 1979, vol. 19(9), pp. 553–8.

M. Takahashi, H. Matsumoto, and T. Saito: ISIJ Int., 1995, vol. 35(12), pp. 1452–8.

L. Schiller and Z. Naumann: Z. Ver. Deutsch. Ing., 1935, vol. 77, pp. 318–20.

R. Mei and J.F. Klausner: Int. J. Heat Fluid Fluid Flow., 1994, vol. 15(1), pp. 62–5.

O. Simonin and P.L. Viollet: Phenomena in multiphase flows, Hemisphere Publ. Corp, Washington, DC, 1990, pp. 259–69.

S. Elghobashi and T. Abou-Arab: The Physics of Fluids., 1983, vol. 26(4), pp. 931–8.

M.J. Hounslow, R.L. Ryall, and V.R. Marshall: AIChE J., 1988, vol. 34(11), pp. 1821–32.

H. Luo: Ph.D. Dissertation, The Norwegian Institute of Technology, Trondheim, 1993.

H. Luo and H. Svendsen: AIChE J., 1996, vol. 42(5), pp. 1225–33.

Y.G. Park, K.W. Yi, and S.B. Ahn: ISIJ Int., 2001, vol. 41(5), pp. 403–9.

B. Zhu, Q. Liu, D. Zhao, S. Ren, M. Xu, B. Yang, and B. Hu: Steel Res Int., 2016, vol. 87(2), pp. 136–45.

H.T. Ling and L.F. Zhang: Metall Mater. Trans. B., 2019, vol. 50(4), pp. 2017–28.

C.G. Méndez, N. Nigro, and A. Cardona: J. Mater. Process. Tech., 2005, vol. 160, pp. 296–305.

H.J. Duan, Y. Ren, and L.F. Zhang: JOM., 2018, vol. 70(10), pp. 2128–38.

W. Chen and L.F. Zhang: Metall Mater. Trans. B., 2021, vol. 52(1), pp. 528–47.

S.P. Pudasaini: Int. J. Multiphas. Flow., 2019, vol. 113, pp. 142–52.

P. Shiva: Pudasaini J. Geophys. Res-earth., 2012, vol. 117(F03010), pp. 1–28.

L. Neves, C.A.R. Carneiro, R.F. Reis, and R.P. Tavares: Comput. Methods Mater. Sci., 2010, vol. 10(4), pp. 207–13.

Acknowledgments

The authors wish to express thanks to the financial supports of the National Natural Science Foundation of China (Grant No. 52104321), the Natural Science Foundation of Chongqing, China (Grant No. cstc2020jcyj-msxmX0177), and the Science and Technology Research Program of Chongqing Municipal Education Commission (Grant Nos. KJQN201801413 and KJQN202101404).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 9 2021; accepted October 10 2021.

Rights and permissions

About this article

Cite this article

Chen, G., He, S. Hydrodynamic Modeling of Two-Phase Flow in the Industrial Ruhrstahl–Heraeus Degasser: Effect of Bubble Expansion Models. Metall Mater Trans B 53, 208–219 (2022). https://doi.org/10.1007/s11663-021-02357-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02357-6