Abstract

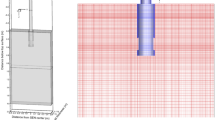

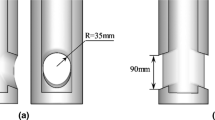

A transient three-dimensional mathematical model is developed to study the slag entrapment in a continuous-casting mold. The unsteady turbulent flow is computed using the large eddy simulation (LES). The sub-grid scale structure is modeled by Smagorinsky–Lilly model. The movements of discrete bubbles, as well as three continuous phases (air-slag-steel) are described by solving the coupled discrete particle model (DPM) and volume of fraction (VOF) model. Comparisons are made between the plant measurements and predicted result of level fluctuations near the submerged entry nozzle (SEN), and good agreements are obtained. Results reveal that the average velocity, transverse velocity of slag-metal interface are not accurate to evaluate the seriousness of slag entrapment in mold, because the surface velocity is also affected by bubble movements. By comparison, the variation trend of maximum velocity of slag-metal interface shows good agreements with that of the slag drops and therefore can be used to evaluate the slag entrapment in mold. Then considering interfacial tension force, mold size, impinging angle, port angle, impinging velocity and depth, a new dimensionless value of “J” is established to evaluate the seriousness of slag entrapment. Through comparing with traditional “F value”, the J value shows remarkable advantages in predicting slag entrapment in mold with different widths and volume flow rates of argon. The results are beneficial for controlling slag entrapment during continuous casting process.

Similar content being viewed by others

References

L.C. Hibbeler and B.G. Thomas: Iron Steel Technol., 2013, vol. 10, pp. 121–36. .

X.L. Li, B.K. Li, Z.Q. Liu, R. Niu, Y.Q. Liu, C.L. Zhao, C.D. Huang, H.S. Qiao, and T.X. Yuan: Metals., 2019, vol. 9(1), pp. 1–10. .

S. Yamashita and M. Iguchi: ISIJ Int., 2001, vol. 41(12), pp. 1529–31. .

J. Savolainen, T. Fabritius, and O. Mattila: ISIJ Int., 2009, vol. 49(1), pp. 29–36. .

M. Iguchi, J. Yoshida, T. Shimizu, and Y. Mizuno: ISIJ Int., 2000, vol. 40(7), pp. 685–91. .

D. Gupta and A.K. Lahiri: Ironmak. Steelmak., 1996, vol. 23(4), pp. 361–3. .

J. Mietz, S. Schneider, and F. Oeters: Steel Res. Int., 1991, vol. 62(1), pp. 10–5. .

H. Lei, M.Y. Zhu, and J.C. He: Acta Metall. Sin., 2000, vol. 36(10), pp. 1113–7. .

A. Sharan and A.W. Cramb: Metall. Mater. Trans. B., 1995, vol. 26(1), pp. 87–94. .

Y. Chung and A.W. Cramb: Metall. Mater. Trans. B., 2000, vol. 31(5), pp. 958–71. .

J.M. Harman and A.W. Cramb: 79rd Steelmaking Conference Proceedings. Iron and Steel Society, Pittsburgh, 1996, pp. 773–84.

M. Saeedipour, S. Puttinger, N. Doppelhammer, and S. Pirker: Chem. Eng. Sci., 2019, vol. 198, pp. 98–107. .

Z.Q. Liu, Z.B. Sun, and B.K. Li: Metall. Mater. Trans. B., 2017, vol. 48(2), pp. 1248–67. .

S.M. Cho, B.G. Thomas, and S.H. Kim: Metall. Mater. Trans. B., 2019, vol. 50(1), pp. 52–76. .

X.L. Li, B.K. Li, Z.Q. Liu, R. Niu, and X.C. Huang: Steel Res. Int., 2019, vol. 90(4), pp. 1800133.

Z.Q. Liu, B.K. Li, M.F. Jiang, and F. Tsukihashi: ISIJ Int., 2014, vol. 54(6), pp. 1314–23. .

Z.Q. Liu, B.K. Li, M.F. Jiang, and F. Tsukihashi: ISIJ Int., 2013, vol. 53(3), pp. 484–92. .

B.G. Thomas, Q. Yuan, S. Mahmood, R. Liu, and R. Chaudhary: Metall. Mater. Trans. B., 2014, vol. 45(1), pp. 22–35. .

X.L. Li, B.K. Li, Z.Q. Liu, R. Niu, and Q. Liu: ISIJ Int., 2018, vol. 58(11), pp. 2052–61. .

Z.Q. Liu, L.M. Li, and B.K. Li: JOM., 2016, vol. 68(8), pp. 2180–90. .

M. Bielnicki and J. Jowsa: Steel Res. Int., 2018, vol. 89(9), p. 1800110. .

X.L. Li, B.K. Li, Z.Q. Liu, R. Niu, Q. Liu, X.C. Huang, G.D. Xu, and X.M. Ruan: Steel Res. Int., 2019, vol. 90(3), p. 1800423. .

S. Kunstreich and P.H. Dauby: Ironmak. Steelmak., 2005, vol. 32(1), pp. 80–6. .

Y. Wang, S.F. Yang, F. Wang, and J.S. Li: Materials., 2019, vol. 12(11), pp. 1–20. .

T. Zhang, J. Yang, and P. Jiang: Metals., 2019, vol. 9(1), pp. 1–9. .

A. Theodorakakos and G. Bergeles: Metall. Mater. Trans. B., 1998, vol. 29(6), pp. 1321–7. .

G.A. Panaras, A. Theodorakakos, and G. Bergeles: Metall. Mater. Trans. B., 1998, vol. 29(5), pp. 1117–26. .

H. Mizukami, M. Hanao, S. Hiraki, M. Kawamoto, T. Watanabe, A. Hayashi, and M. Iguchi: Tetsu-to-Hagané., 2000, vol. 86(4), pp. 265–70. .

J. Yoshida, M. Iguchi, and S. Yokoya: Tetsu-to-Hagané., 2001, vol. 87(8), pp. 9–15. .

T. Teshima, M. Osame, K. Okimoto, and Y. Nimura: Steelmaking Conference Proceedings, Transactions of the Iron and Steel Institute of Japan, Tokyo, 1988, pp. 111–18.

L.F. Zhang, J. Aoki, and B.G. Thomas: Metall. Mater. Trans. B., 2006, vol. 37(3), pp. 361–79. .

D. Gupta and A. Lahiri: Metall. Mater. Trans. B., 1994, vol. 25(2), pp. 227–33. .

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51974071 and 51874203), Young Elite Scientists Sponsorship Program by CAST (No. 2018QNRC001), and Fundamental Research Funds for the Central Universities (No. N182505039).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted February 13, 2020; accepted June 5, 2021

Rights and permissions

About this article

Cite this article

Li, X., Li, B., Liu, Z. et al. Evaluation of Slag Entrapment in Continuous Casting Mold Based on the LES-VOF-DPM Coupled Model. Metall Mater Trans B 52, 3246–3264 (2021). https://doi.org/10.1007/s11663-021-02253-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02253-z