Abstract

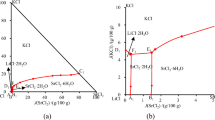

The thermodynamic information of the CaO-SiO2-Nb2O5-La2O3 system is of great significance for the utilization of Nb and RE resources from minerals. In this article, the phase equilibria of the CaO-SiO2-Nb2O5-La2O3 system were investigated by equilibrium experiments. Twelve kinds of phase equilibria were determined, and then a spatial liquidus phase diagram was constructed. The primary phase fields of SiO2, CaNb2O6, LaNbO4, Ca2Nb2O7 and CaSi3La4O13 were determined, respectively. Meanwhile, the liquidus surfaces in the primary phase fields of SiO2, Ca2Nb2O7 and LaNbO4 were determined. Finally, the CaO-SiO2-Nb2O5-(17.5, 20, 22.5, 25 pct)La2O3 pseudo-ternary phase diagrams were also obtained. In addition to the experimental results, two theoretical rules applicable for the spatial quaternary phase diagram were also proposed to obtain indirect information on the bivariate interface between two adjacent primary phase fields. The first rule was the “tangent line rule” for judging related precipitation reaction types, and the second rule was the “highest temperature rule” for judging related temperature trends. The present work will be helpful for the utilization of Nb and RE resources and for the establishment of related thermodynamic databases.

Similar content being viewed by others

Reference

Yandong Li, Tongsheng Zhang, Chengjun Liu and Maofa Jiang: Met., 2019, vol. 9, pp. 433.

Hong Tao, Chunlin Zhao, Ran Zhang and Jiagang Wu: J. Alloys Compd., 2019, vol. 795, pp. 401-07.

Junxiang Ning, Peiyang Shi, Maofa Jiang, Chengjun Liu and Xiaoliang Li: Nanomater, 2019, vol. 9, pp. 1039.

Xueyu Tan: Niobium Industry in China, 1st ed., Metallurgical Industry Press, Beijing, 2015, pp. 24-31.

Xiaowei Huang and Hongwei Li: Rare Earth in China, 1st ed., Metallurgical Industry Press, Beijing, 2015, pp. 81-153.

Donglu Lin, Chunlong Li and Hulin Wu: Key Research and Technical Progress of Mining and Smelting Technology in Bayan Obo Special Mineral, 1st ed., Metallurgical Industry Press, Beijing, 2007, pp. 1-42.

XiuLan Yu, Li Bai, QingChun Wang, Jia Liu, MingYu Chi and ZhiChang Wang: Metall. Mater. Trans. B, 2012, vol. 43, pp. 485-93.

Bo Zhang, Chengjun Liu, Chunlong Li and Maofa Jiang: Miner. Eng., 2014, vol. 65, pp. 17-23.

Bo Zhang, Chengjun Liu, Chunlong Li and Maofa Jiang: Int. J. Miner. Process, 2016, vol. 150, pp. 16-23.

Shangyi Li, Yusheng Zhou, Huayun Du and Guihua Qian: Development and Application Technology of Niobium Resources, 1st ed., Metallurgical Industry Press, Beijing, 1992, pp. 107-200.

J. R. Taylor and A. T. Dinsdale, Calphad, 1990, vol. 14, pp. 71-88.

T. L. Barry: Kinetics, phase equilibria, and crystal chemical studies in rare earth oxide-alkaline earth oxide systems (Thesis). 1964.

E. P. Savchenko, N.A. Godina and E. K. Keler (1969) Solid-phase reactions between pentoxides of niobium and tantalum and oxides of the rare-earth elements, In: Toropov NA (ed.), Chemistry of High-Temperature Materials. New York: Plenum Press

B. Pilarek, A. J. Pelczarska and I. Szczygieł: Ceram. Int., 2019, vol. 45, pp. 1562-68.

N. A. Toropov and I. A. Bondar: Russ. Chem. Bull., 1961, vol. 10, pp. 1278-85.

M. Ibrahim and N. F. H. Bright: J. Am. Ceram. Soc., 1962, vol. 45, pp. 221-22.

Chengjun Liu and Jiyu Qiu: J. Eur. Ceram. Soc., 2018, vol. 38, pp. 2090-97.

A. M. Frolov and A. A. Evdokimov: Russ. J. Inorg. Chem., 1987, vol. 32, pp. 1771-3.

A. Jongejan and A. L. Wilkins: J. Less-Common Met., 1969, vol. 19, pp. 203-08.

Mao Chen and Baojun Zhao: J. Am. Ceram. Soc., 2013, vol. 96, pp. 3631-36.

Mao Chen, Ximei Hou, Junhong Chen and Baojun Zhao: Metall. Mater. Trans. B, 2016, vol. 47, pp. 1690-96.

Xiaodong Ma, Dianwei Zhang, Zhixing Zhao, Tim Evans and Baojun Zhao: ISIJ Int., 2016, vol.4, pp.513-19.

Lifeng Sun, Junjie Shi, Zhe Yu and Maofa Jiang: Ceram Int., 2019, vol. 45, pp. 481-87.

Baijun Yan, Xu Wang and ZhanBing Yang: J. Alloys Compd., 2017, vol. 695, pp. 3476-83.

Nan Wang, Weijun Huang, Shuaichao Chen and Min Chen: J. Iron Steel Res. Int., 2012, vol. 19, pp. 8-12.

Hector M. Henao, Claudio Pizarro, Jonkion Font, Alex Moyano, Peter C. Hayes and Evgueni Jak: Metall. Mater. Trans. B, 2010, vol. 41, pp. 1186-93.

Xu Gao, Hiroyuki Matsuura, Masaki Miyata and Fumitaka Tsukihashi: ISIJ int., 2013, vol. 53, pp. 1381-85.

Lifeng Sun and Junjie Shi: ISIJ Int., 2019, vol. 59, pp. 1184-91.

Jiyu Qiu, Chengjun Liu, Zhengyue Liu and Zhe Yu: Ceram. Int., 2019, vol. 45, pp. 2281-88.

Jiyu Qiu, Chengjun Liu, Zhengyue Liu and Zhe Yu: J. Rare Earths, 2019, vol. 38, pp.100-107.

Fengman Shen: Physical chemistry of metallurgy, Beijing, Higher Education Press, 2017, pp. 86-126.

Jiyu Qiu and Chengjun Liu: Metall. Mater. Trans. B, 2018, vol. 49, pp.69-77.

Acknowledgments

This work was supported by the National Key R&D Program of China (No. 2017YFC0805100) and National Natural Science Foundation of China (NSFC, No. 51874082).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 12, 2019.

Rights and permissions

About this article

Cite this article

Qiu, J., Liu, C., Liu, Z. et al. Liquidus Phase Diagram of CaO-SiO2-La2O3-Nb2O5 System with w(La2O3) = 15 to 25 Pct. Metall Mater Trans B 51, 1190–1200 (2020). https://doi.org/10.1007/s11663-020-01818-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01818-8