Abstract

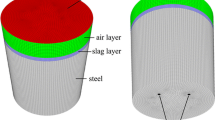

Mixing time, slag eye area, and wall shear stress in a ladle fitted with dual plugs have been studied as a function of operating variables, namely, gas flow rate, radial nozzle position, separation angle between nozzles and flow rate partitioning. While the mixing time and slag eye area have been experimentally investigated in a scaled water model (with and without a top slag layer), the shear stress on the vessel wall has been studied computationally via a RANS-based turbulent, three-dimensional coupled Eulerian–Lagrangian (VOF-DPM), multiphase flow model. Experimental and computational results have indicated that the mixing, eye area, and wall shear stress depend on the gas flow rate, i.e., while mixing efficiency increases with the increasing gas flow rate, the slag eye area, and wall shear stress, in contrast, become more pronounced with the increasing gas flow, leading to an undesirable operating regime. The radial nozzle position, separation angle between the nozzles and flow rate partitioning at any given flow rate also influence the ladle process performance, influencing the mixing, eye area, and wall shear stress, albeit to a varied degree. Within the range of operating conditions studied, an expected inverse correspondence between mixing time and shear behavior was observed. Experimental and computational results in conjunction have indicated that the best arrangement of porous plugs or gas injection nozzles for superior ladle process performance is dependent on the gas flow rate and is specific to the desired objective (i.e., decreasing the mixing time, or slag eye area and wall shear stress). Hence, a unique gas injection practice cannot and should not be suggested as the optimum for ladle metallurgy in steelmaking. Nevertheless, if the mixing time is the parameter of primary interest, a nozzle configuration with equal flow partitioning (1:1) between the nozzles and identical nozzle radial positions (0.7R/0.7R, 45 deg) should suffice for both low and high gas flow rates. In contrast, a nonidentical nozzle radial position (0.7R/0.5R, 90 deg) and an unequal gas flow rate per nozzle (1:3) appear preferable if both ladle eye and shear stresses, rather than mixing, are the issues of concern.

Similar content being viewed by others

Notes

Identical nozzle radial position indicates that both nozzles are equidistant from the center of a ladle. Therefore, if R is the radius of a ladle, r is the nozzle radial position or, X = r/R is the fractional or nondimensional radial position, then the nozzle radial position is r = XR, where X = 0 represents the center of the ladle and X = 1, represents the ladle wall.

Abbreviations

- α :

-

Volume fraction

- C D :

-

Bubble drag coefficient

- C μ, C 1, C 2, C 1ε G k, G ε, Y m :

-

Semiempirical coefficients for turbulence modeling

- D :

-

Molecular diffusivity, m2/s

- D t :

-

Turbulent diffusivity

- D eff :

-

Effective diffusivity

- d b :

-

Bubble diameter

- d n :

-

Nozzle diameter, m

- ε :

-

Turbulence dissipation rate, m2/s3

- g :

-

Gravitational acceleration, 9.81 m/s2

- H :

-

Height of water in bath

- k :

-

Kinetic energy of turbulence, m2/s2

- κ :

-

Interface curvature, m−1

- λ :

-

Scale factor

- m:

-

Mass

- M:

-

Concentration, gm/dcl

- μ :

-

Dynamic viscosity, Pa.s

- μt :

-

Turbulent viscosity

- μ eff :

-

Effective viscosity

- ν :

-

Kinematic viscosity, m2/s

- p :

-

Pressure (dynamic), Pa

- Q :

-

Gas flow rate, Nl/min

- R :

-

Vessel radius

- r :

-

Direction vector

- ρ :

-

Density, kg/m3

- S 1 :

-

Area-averaged shear stress near nozzles, Pa

- S 2 :

-

Area-averaged shear stress away from nozzles, Pa

- σ :

-

Surface tension (N/m)

- T :

-

Temperature, °C

- t :

-

time, s

- u :

-

Velocity, m/s

- mix:

-

Mixture

- b:

-

Bubble (dispersed air)

- g:

-

Gas (air continuum)

- l:

-

Liquid (water)

- i:

-

Chemical species (tracer)

References

D. Mazumdar, P. Dhandapani and R. Sarvanakumar: ISIJ Int., 2017, vol. 57, pp. 286–295.

N.J. Themelis and P. Goyal: Canad. Met. Quart., 1983, vol. 22, pp. 313-320.

J.K Brimacombe: in Int. Symp. Injection in process metallurgy, T. Lehner et al., eds., TMS, USA, 1991, pp. 13-42.

D. Mazumdar and R.I.L. Guthrie: ISIJ Int., 1995, vol. 35, pp. 1-20.

D. Mazumdar and J.W. Evans: ISIJ Int., 2004, vol. 44, pp. 447-461.

A.N. Conejo and S. Kitamura: Bull. Adv. Matls. Proc. Building IMRAM, 2009, vol. 65, pp. 26-35.

A.N. Conejo and S. Kitamura: Bull. Adv. Matls. Proc. Building IMRAM, 2009, vol. 65, pp. 36-46.

G. Irons, A. Senguttuvan and K. Krishnapisharody: ISIJ Int., 2015, vol. 55, pp. 1–6

N. Conejo: European Steel Technology and Application Days, 2017, June 26 – July 1, Vienna, Austria.

K. Nakanishi, T. Fujii and J. Szekely: Ironmaking and Steelmaking, 1975, vol. 2, pp. 193-197.

S. Asai, T. Okamoto, J. He and I. Muchi: Trans. ISIJ, 1983, vol. 23, pp. 43-50.

M. Sano and K. Mori: Trans. ISIJ, 1983, vol. 23, pp. 169-175.

S. Joo and R. I. L. Guthrie: Metall. Trans. B, 1992. vol. 23B, pp. 765-778.

M.-Y. Zhu, T. Inomoto, I. Sawada and T.-C. Hsiao: ISIJ Int., 1995, vol. 35, pp. 472-479.

L. Zhang, S. Taniguchi, K. Cai and Y. Qu: Steel Res., 2000, vol. 71, pp. 325-332.

M.A.C. Terrazas and A.N. Conejo. Metall. and Matls. Trans. B, 2015, Vol. 46, pp.711-718.

L. W. Helle: J. South Afr. Inst. Min. Met., 1981, pp. 329-337.

H. Turkoglu and B. Farouk: ISIJ Int., 1991, vol. 31, pp. 1371-1380

C. Chen, G. Cheng, H. Sun, Z. Hou, X. Wang and J. Zhang: Steel Res. Int., 2012, vol. 83, pp. 1141-1151.

J. Mietz and F. Oeters: Canad. Met. Quart., 1989, vol. 28, pp. 19-27.

Chattopadhyay, K.; Sengupta A.; Ajmani S.; Lenka, S.; Singh, V: Ironmaking and steelmaking, 2009, vol. 36, pp. 537-542.

L. Jardón, A. Amaro, A. N. Conejo, C. González and M. A. Ramírez: Matls. and Manuf. Proc., 2018, vol. 33, pp. 882-890.

O. Haida and J. K. Brimacombe: Trans. ISIJ, 1985, vol. 25, pp. 15-20.

N. B. Ballal and A. Ghosh: Metall. Trans. B, 1981, vol. 12, pp. 525-534.

R. Singh, D. Mazumdar and A. K. Ray: ISIJ Int., 2008, vol. 48, pp. 1033–1035.

D. Mazumdar: Metall. Trans. B, Vol. 1990, vol. 21B, pp. 925-928.

S. Pinho and E. A. Macedo: J. Chem. Eng. Data, 2005, vol. 50, pp. 29-32.

J.F. Davidson and B.O.G. Schüler, Trans. Inst. Chem. Eng., 1960, Vol. 38, pp. 385-42

P. C. Pistorius, Treatise on Proc. Metall., 2014, Vol. 2, pp.179-96

Q. Cao and L. Nastac. JOM. 2018, Vol. 70, 2071-2081.

S.T Johansen and F. Boysan: Metall. Trans. B, 1988, vol 19B, pp.755-764.

T-H. Shih, W. W. Liou, A. Shabbir, Z. Yang and J. Zhu: Computers & Fluids, 1995, vol. 24, pp. 227-238.

F. M. White: Fluid Mechanics, 7th Edition, McGraw Hill, NY, 2010, p. 467.

S. Chatterjee, D. Li, and K. Chattopadhyay: Metall. and Matls. Trans. B, 2018, vol. 49, pp 756–766.

G. Chen, S. He and Y. Li: Metall. and Matls. Trans. B, 2017,48, p.2176.

D. Mazumdar: Steel Res. Intl., 2018, “in press”

Ansys Fluent version 18: Theory Guide.

D. Mazumdar, H. Nakajima and R. Guthrie, Metall. Trans. B, 1988, vol. 19B, pp 507-510.

T. Haiyan, G. Xiaochen, W. Guanghui and W. Yong: ISIJ Int., 2016, vol. 56, pp. 2161-2170.

Acknowledgments

One of the authors (AC) acknowledges the financial support from the Mexican government through TecNM Grant 5794.16-P to conduct the experimental work and the assistance of undergraduate student Oscar Guzmán Guerrero. Simulation was carried out using the High Performance Computing clusters HPC 2010 and 2013 at the Computer Center, IIT Kanpur.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 13, 2018.

Rights and permissions

About this article

Cite this article

Conejo, A.N., Mishra, R. & Mazumdar, D. Effects of Nozzle Radial Position, Separation Angle, and Gas Flow Partitioning on the Mixing, Eye Area, and Wall Shear Stress in Ladles Fitted with Dual Plugs. Metall Mater Trans B 50, 1490–1502 (2019). https://doi.org/10.1007/s11663-019-01546-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-019-01546-8