Abstract

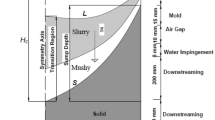

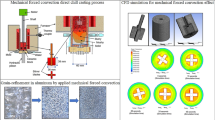

Experimental techniques remain reliable approaches for investigating the effects of parameters of the direct chill (DC) casting process on macrosegregation, grain structure formation, and surface quality. However, experimental analysis methods of these effects are expensive and can often prove difficult to implement. Understanding of the complex physics of the solidification process remains limited, and this makes it indispensable to use accurate numerical modeling tools as a complement to experiments. Numerical modeling without consideration of turbulent flow is unsuitable for application to solidification occurring during DC casting, since significant turbulent flow exists in the upper section of the cast, where the liquid pool exists. The present work employed a low-Re \( v^{2}{-}f\) turbulence model and a dual-zone solidification flow model to predict the melt flow pattern, turbulence level, sump depth, transition zone thickness, and mushy zone thickness in the DC casting of Al-Cu alloy. The obtained results provided evidence of significant damping of the flow in the slurry zone. Furthermore, results of different simulation cases revealed a narrower transition zone and shallower sump.

Similar content being viewed by others

References

D.G. Eskin: Physical metallurgy of direct chill casting of aluminum alloys, CRC Press, Boca Raton, 2008, pp. 1-18.

J.F. Grandfield and P.T. Mcglade: Mater. Forum, 1996, vol. 20, pp. 29-51

C. Devadas and J.F. Grandfield., Experiences with Modeling Dc Casting of Aluminum, in Proceedings of the 120th TMS Annual Meeting Light Metals, TMS Annual Meeting: TMS (The Minerals, Metals and Materials Society), 1990, pp. 883-92.

[4] S. C. Flood, L. Katgerman, V.R. Voller, in: M. Rappaz, M.R. Ozgu, K.W. Martin (Eds.): The Minerals, Metals and Materials Society, Warrendale, USA, 1991, pp. 683-690.

[5] C.J. Vreeman, M. J. M. Krane, F.P. Incropera: Int. J. Heat Mass Transfer, 2000, vol. 43, pp. 677-686.

C.J. Vreeman, F.P. Incropera: Int. J. Heat Mass Transfer, 2000, vol. 43, pp. 687-704.

[7] R.S. Rerko, H.C.D. Groh, C, Beckermann: Mater. Sci. and Eng. A, 2003, vol. 347, pp. 186-197.

[8] M. Zaloznik, B. Sarler, D. Gobin: Mater. Technol., 2004, vol. 38, pp. 249-255.

[9] D.G. Eskin, J. Zuidema, V. I. Savran, L. Katgerman: Mater. Sci. Eng. A, 2004, vol. 384, pp. 232-244.

[10] Q. Du, D.G. Eskin, L. Katgerman: Mater. Sci. Eng. A, 2005, vol. 413-414, pp. 144-150.

A. Jafari, S.H. Seyedein, M.R. Aboutalebi, D.G. Eskin, L. Katgerman: Iran. J. Mater. Sci. Eng., 2010, vol. 7, pp. 39-50.

[12] S. Verma, A. Dewan, Metall. Mater. Trans. B, 2014, vol.45, pp. 1456-1471.

[13] S. Asian and J. Szekely, Ironmak. Steelmak, 1975, vol. 3, pp. 205-13

P.J. Flint: Steelmak. Conf. Proc., 1990, pp. 481-90

[15] X. Huang, B.G. Thomas, F. M. Najjar: Metall. Mater. Trans. B 1992, Vol. 23 pp. 339-356.

[16] B.Q. Li: J. Mater. Process. Technol., 1995, vol. 55, pp. 351-359.

[17] W. Shyy, Y. Pang, G.B. Hunter, D.Y. Wei, M. H. Chen: Int. J. Heat Mass Transf., 1992, vol. 35, pp. 1229-1245.

[18] S. Chakraborty, N. Chakraborty, P. Kumar, P. Dutta: Int. J. Heat Mass Transf, 2003, vol. 46, pp. 1115-1137.

[19] C.M. Oldenburg, F.J. Spera: Numer. Heat Transfer, Part B, 1992, vol. 21, pp. 217-229.

L. Zhang, D.G. Eskin, A. Miroux, T. Subroto, L. Katgerman: IOP Conf. Series Mater. Sci. Eng., 2012, vol. 33, pp. 1-7.

[21] D. Mortensen: Metall. Mater. Trans. B, 1999, vol. 30B pp. 119.

[22] L. Begum, M. Hasan: Numer. Heat Transfer, Part A, 2015, vol. 67, pp.719-745.

[23] B.E. Launder, B.I. Sharma: Lett. Heat. Mass Transfer, 1974, vol. 1, pp. 131-137.

[24] P.A. Durbin: J.Theor. Comput. Fluid Dyn., 1991, vol. 3, pp. 1-13.

[25] F.S. Lien, G. Kalitzin: Int. J. Heat Fluid Flow, 2001, vol. 22, pp. 53-61.

[26] A. Sveningsson, L. Davidson: Int. J. Heat Fluid Flow, 2004, vol. 25, pp. 785-794.

[27] D.R. Laurence, J.C. Uribe, S.V. Utyuzhnikov: Flow Turbulence Combust, 2004, vol. 73, pp. 169-185.

F.S. Lien and P.A. Durbin: Non-linear k-v2 modeling with application to high lift, Proceedings of 1996 Summer Programme, 1996, pp. 5-22.

[29] B.R. Kazerooni, and S.K. Hannani: Trans. B: Mechanical Engineering, 2009, vol. 16, pp. 159-167.

[30] S. Chang, D.M. Stefanescu: Metall. Trans. A, 1996, vol. 27A, pp. 2708-2721

[31] G. Poole, N. El-Kaddah: ISIJ Inter., 2014, vol. 54, pp. 321-327.

[32] W.D. Bennon, F.P.Incropera: Int. J. Heat Mass Transfer, 1987, vol. 30, pp. 2161-2170

[33] V.R. Voller, C. Prakash: Int. J. Heat Mass Transfer 1987, vol. 30, pp.1709-1719.

[34] D.R. Poirier: Metall. Trans. B, 1987, vol. 18, pp. 245-255.

J. Sengupta, S.L. Cockcroft, D.M. Maijer, M.A. Wellsand, A. Larouche: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 523-540.

[36] Suyitno, W.H. Kool, L. Katgerman: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 2917-2926.

E.D. Suyitno, D.G. Eskin, V.I. Savran, L. Katgerman: Metall. Mater. Trans. A, 2004, vol. 35A, pp. 3551-3561

ANSYS FLUENT 16.0, ANSYS, Inc., Canonsburg, PA, 2011.

[39] I.B. Celik, U. Ghia, P.J. Roache, C.J. Freitas, H. Coleman, P.E. Raad: J. Fluids Eng., 2008, vol.130, pp. 1-4

[40] D.G. Eskin, V.I. Savran, L. Katgerman: Metall. Mater. Trans. A, 2005, vol. 36, pp. 1965-1976.

[41] B.C.H. Venneker, L. Katgerman: J. Light Metals, 2002, vol. 2, pp. 149-159.

[42] D.G. Eskin, Q. Du, L. Katgerman: Metall. Mater. Trans. A, 2008, vol. 39A, pp.1206-1212.

Dewan, A: Tackling Turbulent Flows in Engineering, Springer, New York, 2010, pp. 59-79.

Acknowledgment

This work was conducted under the sponsorship of the Tertiary Education Trust Fund (TETFUND) (www.tetfund.gov.ng).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 19, 2018.

Rights and permissions

About this article

Cite this article

Nzebuka, G.C., Waheed, M.A., Kuye, S.I. et al. Accounting for Melt Flow Pattern and Solid Fraction Evolution in DC Casting of Al-Cu Alloy Using \( v^{2}{-}f \) Turbulence Model. Metall Mater Trans B 50, 866–880 (2019). https://doi.org/10.1007/s11663-018-01502-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-018-01502-y