Abstract

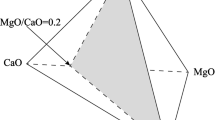

Slags play an important role in blast furnace operation, and their compositions are based on the CaO-SiO2-MgO-Al2O3 quaternary system in many steel companies. The binary basicity (CaO/SiO2 weight ratio) of blast furnace slags, especially primary slag and bosh slag, can be as high as 1.5 or higher. Phase equilibria and liquidus temperatures in the CaO-SiO2-MgO-Al2O3 system with binary basicity of 1.50 are experimentally determined for temperatures in the range 1723 K to 1823 K (1450 °C to 1550 °C). High temperature equilibration, quenching, and electron probe X-ray microanalysis techniques have been used in the present study. The isotherms are obtained in the primary phase fields of Ca2SiO4, melilite, spinel, periclase, and merwinite related to blast furnace slags. Effects of Al2O3, MgO, and binary basicity on liquidus temperatures have been discussed. In addition, extensive solid solutions have been measured for different primary phases and will be used for development and optimization of the thermodynamic database.

Similar content being viewed by others

References

X. L. Wang: Ferrous Metallurgy (Ironmaking Part), China Metallurgical Industry Press, Beijing, 1991. (In Chinese)

A. K. Biswas: Principles of blast furnace ironmaking, Cootha Publishing House, Brisbane, 1981.

K. Sunahara, K. Nakano, M. Hoshi, T. Inada, S. Komatsu, and T. Yamamoto: ISIJ Int., 2008, vol. 48, pp. 420-429.

E. F. Osborn, R. C. DeVries, K. H. Gee, and H. M. Kraner: Trans. AIME, 1954, 6: 33-45.

W. Gutt and A. D. Russel: J. Mater. Sci., 1977, vol. 12, pp. 1869-1878.

G. Cavalier and M. Sandrea-Deudon: Rev. Metall., 1960, vol. 57, pp. 1143-1157.

A. T. Prince, J. Am. Ceram. Soc., 1954, vol. 37, pp. 402-408.

F. Dahl, J. Brandberg, and S. Du: ISIJ Int., 2006, vol. 46, pp. 614-616.

J. Gran, Y. Wang, and S. Du: Calphad, 2011, vol. 35, pp. 249-254.

J. Gran, B. Yan, and S. Du: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 1008-1016.

D. Zhang, E. Jak, P. Hayes, and B. Zhao: 4th Annual High Temperature Processing Symposium, Swinburne University of Technology, Melbourne, 2012, pp. 16–18.

X. Ma, G. Wang, S. Wu, J. Zhu, and B. Zhao: ISIJ Int., 2015, vol. 55, pp. 2310-2317.

C. W. Bale, P. Chartrand, S. A. Degterov, G. Eriksson, K. Hack, R. B. Mahfoud, J. Melançon, A. D. Pelton, and S. Petersen: Calphad, 2002, vol. 26, pp. 189-228.

S. Yi and Y. Seonghoon: Steel Res. Int., 2003, vol. 74, pp. 413-417.

J. Ma: ISIJ Int., 1999, vol. 39, pp. 697-704.

M. Chen and B. Zhao: J. Am. Ceram. Soc., 2013, vol. 96, pp. 3631-3636.

B. Zhao, E. Jak, and P. Hayes: ISIJ Int., 2005, vol. 45, pp. 1019-1026.

B. Zhao, E. Jak, and P. Hayes: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 597-605.

V. D. Eisenhuttenleute: Slag Atlas 2 nd ed., Verlag Sthaleisen GmbH, Düsseldorf, 1995.

O. Žigo, K. A. L. Kosa, I. Nerád, and I. Proks: Chem. Papers, 1987, vol. 41, pp.171-181.

Acknowledgments

The financial supports from the Baosteel-Australia Joint Research and Development Centre (Project BA12002) and the Fundamental Research Funds for the Central Universities (Grant No. FRF-TP-15-065A1) are gratefully acknowledged. The authors also wish to thank Ms. Jie Yu, Mr. Hongquan Liu, and Daniel Jang for the lab assistance in the high temperature experiments, Mr. Ron Rasch and Ms. Ying Yu in Centre for Microscopy and Microanalysis (CMM) at University of Queensland for technical support of EPMA and SEM. The authors also thank China Scholarship Council (CSC) for providing scholarship for Mingyin Kou.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 22, 2015.

Rights and permissions

About this article

Cite this article

Kou, M., Wu, S., Ma, X. et al. Phase Equilibrium Studies of CaO-SiO2-MgO-Al2O3 System with Binary Basicity of 1.5 Related to Blast Furnace Slag. Metall Mater Trans B 47, 1093–1102 (2016). https://doi.org/10.1007/s11663-016-0584-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0584-2