Abstract

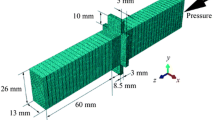

A model for the linear friction welding of the alloy Ti6Al4V was tested experimentally. Instrumented welds were carried out on rectilinear geometries of various dimensions, and the thermal profiles, upset rates, in-plane forces and subsequent micro hardness were measured for comparison. In particular the effects of weld size perpendicular and parallel to the oscillation were investigated, including a case in which the two sides of the weld had different sizes. The predictions of the model were found to be in good agreement with the experimental results, which provides confirmation that the model is useful for the purposes of design.

Similar content being viewed by others

References

M. Maalekian: Sci. Technol. Weld. Joining, 2007, 12, 8, 738-759.

E. Benini: Advances in Gas Turbine Technology, InTech, Rijeka 2011, pp. 411-434.

Rolls-Royce plc: The Jet Engine, 5 edition, 1996 Renault Printing Co. Ltd., Birmingham.

M.E. Nunn: 1st International Conference on Innovation and Integration in Aerospace Sciences. Queens University Belfast, Northern Ireland, 2005.

A. Chamanfar, M. Jahazi, J. Gholipour, P. Wanjara, S. Yue: Metall. Mater. Trans. A, 2010, 42, 3, 729-744.

R. Turner, J.-C. Gebelin, R. M. Ward, R. C. Reed.: Acta Mater., 2011, 59, 10, 3792-3803.

F. Schroeder, R.M. Ward, R.P. Turner, A.R. Walpole, M.M. Attallah, J.-C Gebelin, R.C. Reed: Proc. 9th Int. Trends in Welding Research Conf., Chicago, June 2012, University of Birmingham.

T.J. Ma, W.-Y. Li, S.Y. Yang: Materials Design, 2009, 30, 2128-2132.

P. Wanjara, M. Jahazi: Metall. Mater. Trans. A, 2005, 36, 2149-2164.

A. Mateo, M. Corzo, M. Anglada, J. Mendez, P. Villechaise, J.-P. Ferte, O. Roder: Mater. Sci. Technol., 2009, 25, 7, 905-913.

R. Turner, R.M. Ward, R. March, R.C. Reed: Metal. Mater. Trans. B, 2012, 43,1, 186-197.

I. Bhamji, M. Preuss, P. Threadgill, A.C. Addison: Mater. Sci. Technol., 2011, 27, 1, 2-12.

P. Frankel, M. Preuss, A. Steuwer, P. J. Withers, S. Bray: Mater. Sci Technol., 2009, 25, 5, 640- 650.

M Preuss J QuintadaFonseca, A Steuwer, L Wang, PJ Withers, S Bray (2004). J. Neutron Res.12(1), 165-173.

A. Vairis, M. Frost: Mater. Sci. Eng. A, 2000, 292, 8-17.

R.P. Turner, R.C. Reed: Heat Transfer Effects Arising During the Linear Friction Welding of Ti-6Al-4V, Proc. Titanium 2008, Las Vegas, University of Birmingham.

C. Mary, M. Jahazi: Adv. Mater. Res., 2007, 15-17, 357-362.

A. Vairis, M. Frost: Wear 1998, 217, 117-131.

A. Vairis, M. Frost: Mater. Sci. Eng. A, 1999, 292, 8-17.

DEFORM software: Version 10.2 SFTC, 2545 Farmers Drive, Suite 200, Columbus, OH.

W.-Y. Li, T. Ma, J. Li: J Mater and Design, 2010, 31, 3, 1497-1507.

F. Schroeder: Modelling and Validation of Linear Friction Welding of Ti-6Al-4V for Aeroengine Application PhD thesis, University of Birmingham, Birmingham, 2013.

JMatPro software: Surrey Technology Centre, Guildford.

Acknowledgments

The authors would like to acknowledge the Engineering and Physical Science Research Council (EPSRC) for funding of this project and give thanks to Rolls-Royce plc. for the use of their equipment. The authors would like to thank Mike Rowlson (MD Rowlson Ltd.) for advice and expertise in process modeling.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 24, 2014.

Rights and permissions

About this article

Cite this article

Schroeder, F., Ward, R.M., Turner, R.P. et al. Validation of a Model of Linear Friction Welding of Ti6Al4V by Considering Welds of Different Sizes. Metall Mater Trans B 46, 2326–2331 (2015). https://doi.org/10.1007/s11663-015-0396-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-015-0396-9