Abstract

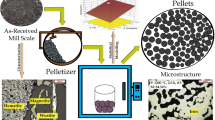

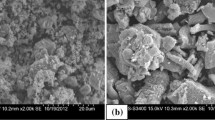

Preparation of the reduced iron powder has been attempted with mill scale as the iron-bearing material and with wood charcoal as the reducing agent through microwave heating. The response surface methodology (RSM) is used to optimize the process conditions, with wood charcoal, process temperature, and holding time being the three process parameters. The regressed model equation eliminating the insignificant parameters through an analysis of variance (ANOVA) was used to optimize the process conditions. The optimum process parameters for the preparation of reduced iron powders have been identified to be the wood charcoal of 13.8 pct, a process temperature of 1391 K (1118 °C), and a holding time of 43 minutes. The optimum conditions resulted in reduced iron powders with a total iron content of 98.60 pct and a metallization ratio of 98.71 pct. X-ray fluorescence (XRF) was used to estimate the elemental contents of the reduced iron powder, which meets the specification of the HY100.23 first-class iron powder standard. Additionally X-ray diffraction (XRD), energy-dispersive spectroscopy (EDS), and scanning electron microscopy (SEM) analysis were performed and the results are compiled.

Similar content being viewed by others

References

Y. Xieting: Powder Metall. Ind., 1997, vol. 7, no. 3, pp. 31-39.

H. Feng-lin: Powder Metall. Ind., 2003, vol. 13, no. 2, pp. 16-21.

W.B. Eisen, B.L. Ferguson, R.M. German, R. Iacocca, P.W. Lee, D. Madan, K. Moyer, H. Sanderow, and Y. Trudel, eds.: ASM Metals Handbook, Powder Metal Technologies and Applications, vol. 7, ASM International, Materials Park, OH, 1998, p. 117.

C. Zhaoding: Powder Metall. Ind., 1994, no. 2, pp. 66–68.

J. Zhihe: Powder Metall. Ind., 1995, no. 5, pp. 169–73.

A. Bose: Metal Powder Report, 2002, vol. 57, pp. 88.

R.K. Sidhu: J. Alloy. Compd., 2002, vol. 346, pp. 250-4.

L. Lefebvre and S. Pelletier: J. Magnet. Magnet. Mater., vol. 176, nos. 2–3, pp. L93–96.

S.B. Bibikov, E.I. Kulikovskij, A.M. Kuznetsov, V.N. Gorshenev, V.V. Orlov, and M.V. Prokof’ jev: Second International Workshop on Ultrawide Band Ultra-short Impulse Signal Proceeding UWBUSIS, 2004, p. 129.

P.B. Jana, A.K. Mallick, and K. De: IEEE Trans. Electromagnet. Compatib., 1992, vol. 34, no. 4, pp. 478-81.

M.A. Solomon, P. Kurian, M.R. Anantharaman, and P.A. Joy: Polym. Plastic Technol. Eng., 2004, vol. 43, no. 4, pp. 1013-28.

Y. Rui-Gang: J. Magnet. Magnet. Mater., 2011, vol. 323, pp. 1805-10.

L. Liu, Y. Duan, L. Ma, S. Liu, and Z. Yu: Appl. Surf. Sci., 2010, vol. 257, pp. 842-6.

A. Volpe, A. Lopez, G. Mascolo, and A. Detomaso: Chemosphere, 2004, vol. 57, no. 7, pp. 579-86.

A. Ghauch, J. Rima, C. Amine, and M. Martin-Bouyer: Chemosphere, 1999, vol. 39, no. 8, pp. 1309-15.

A. Ghauch: Chemosphere, 2008, vol. 71, no. 5, pp. 816-26.

J. Guan, L. Zhou, S. Nie, T. Yan, X. Tang, and W. Pan: Int. J. Pharmaceut., 2010, vol. 383, nos. 1–2, pp. 30–36.

INACG: Nutrition Research, Nutrition Foundation, New York, 1977, pp. 1–29.

M. Arredondo, V. Salvat, F. Pizarro, and M. Olivares: Nutrition Res., 2006, vol. 26, no. 5, pp. 235-39.

C.K. Yeung, D.D. Miller, Z. Cheng, and R.E. Glahn: J. Food Sci., 2005, vol. 70, no. 3, pp. 199-203.

T. Umadevi, M.G. Sampath Kumar, P.C. Mahapatra, T. Mohan Babu, and M. Ranjan: Ironmaking Steelmaking, 2009, vol. 36, pp. 409-15.

S. Cho and J. Lee: Met. Mater. Int.., 2008, vol. 14, pp. 193-96.

W.H. Sutton, M.F. Iskander, and R.L. Beatty: Mater. Res. Soc., 1992, vol. 269, pp. 3-20.

M.S. Venkateshl and G.S.V. Raghavan: Biosyst. Energ., 2004, vol. 88, pp. 1-18.

D. Bas and I.H. Boyac: J. Food Eng., 2007, vol. 78, pp. 836-45.

C. Liyana-Pathirana and F. Shahidi: Food Chem., 2005, vol. 93, no. 1, pp. 47-56.

K. Anupam, S. Dutta, C. Bhattacharjee, and S. Datta: Chem. Eng. J., 2011, vol. 173, no. 1, pp. 135-43.

Z. Erbay and F. Icier: J. Food Eng., 2009, vol. 91, no. 4, pp. 533-41.

V.A.-E. King and R.R. Zall: Food Res. Int., 1992, vol. 25, no. 1, pp, 1-8.

R. Azargohar and A.K. Dalai: Micropor. Mesopor. Mater., 2005, vol. 85, pp. 219-25.

Acknowledgments

Financial support from the National Natural Science Foundation of China (no. 51090385) and the National Basic Research Program of China (no. 2007CB613606) is sincerely acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Manuscript submitted September 24, 2012.

Rights and permissions

About this article

Cite this article

Ye, Q., Zhu, H., Peng, J. et al. Preparation of Reduced Iron Powders from Mill Scale with Microwave Heating: Optimization Using Response Surface Methodology. Metall Mater Trans B 44, 1478–1485 (2013). https://doi.org/10.1007/s11663-013-9872-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-013-9872-2