Abstract

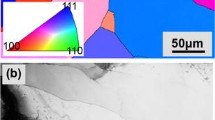

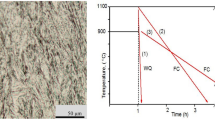

Regions with sharp local texture, called macrozones, are often found in titanium alloy forgings and can reduce fatigue performances. This study observed the evolution of macrozones during hot compression of the Ti–5Al–2Sn–2Zr–4Mo–4Cr alloy in the α + β field. The results show that the macrozones are primarily related to the prior β grains and remained stable during compression. We analyzed the evolution of the β phase inter-structure at various deformation parameters, discussed the role of the primary α grains on the recrystallization of β grains. From studying the microstructural characteristics of the material, the effect of deformation parameters on the microstructure evolution was discussed by combining the effect of the primary α grains. New insights to identify the stability of the macrozones are revealed.

Graphical Abstract

Similar content being viewed by others

References

S.L. Semiatin: Metall. Mater. Trans. A, 2020, vol. 53A, pp. 2593–625.

D. Qin, F. Zhao, Y. Li: Mater. Sci. Eng. A, 2022, vol. 841.

D.G. Leo Prakash, P. Honniball, D. Rugg, P.J. Withers, J. Quinta Da Fonseca, M. Preuss: Acta Mater., 2013, vol. 61(9), pp. 3200–13.

D. Banerjee and J.C. Williams: Acta Mater., 2013, vol. 61(3), pp. 844–79.

A.P. Woodfield, M.D. Gorderman, R.R. Corderman, J.A. Sutliff, B. Yamrom: Proc. 8th World Conf. Titan., Science and Technology, Birmingham, UK, 1995, pp. 1116–23.

N. Gey, P. Bocher, E. Uta, L. Germain, and M. Humbert: Acta Mater., 2012, vol. 60(6–7), pp. 2647–55.

M.G. Glavicic, B.B. Bartha, S.K. Jha, and C.J. Szczepanski: Mater. Sci. Eng. A, 2009, vol. 513–514, pp. 325–28.

J. Qiu, Y. Ma, J. Lei, Y. Liu, A. Huang, D. Rugg, and R. Yang: Metall. Mater. Trans. A, 2014, vol. 45(13), pp. 6075–87.

A.L. Pilchak, R.E.A. Williams, and J.C. Williams: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 106–24.

K. Le Biavant, S. Pommier, and C. Prioul: Fatigue Fract. Eng. Mater. Struct., 2002, vol. 25(6), pp. 527–45.

M.H. Pourian, F. Bridier, P. Pilvin, and P. Bocher: Int. J. Fatigue, 2016, vol. 85, pp. 85–97.

C. Lavogiez, C. Dureau, Y. Nadot, P. Villechaise, S. Hémery: Acta Mater., 2023, vol. 244.

L. Germain, N. Gey, M. Humbert, P. Vo, M. Jahazi, and P. Bocher: Acta Mater., 2008, vol. 56(16), pp. 4298–308.

L. Germain, N. Gey, M. Humbert, P. Bocher, and M. Jahazi: Acta Mater., 2005, vol. 53(13), pp. 3535–43.

Z.B. Zhao, Z. Liu, Q.J. Wang, J.R. Liu, and R. Yang: J. Mater. Sci. Technol., 2019, vol. 35(4), pp. 591–95.

Z.B. Zhao, Q.J. Wang, J.R. Liu, and R. Yang: J. Alloys Compd., 2017, vol. 712, pp. 179–84.

I. Bantounas, D. Dye, and T.C. Lindley: Acta Mater., 2010, vol. 58(11), pp. 3908–18.

A.L. Pilchak, J. Li, and S.I. Rokhlin: Metall. Mater. Trans. A, 2014, vol. 45(10), pp. 4679–97.

Z.B. Zhao, Q.J. Wang, J.R. Liu, and R. Yang: Acta Mater., 2017, vol. 131, pp. 305–14.

Z.B. Zhao, Q.J. Wang, H. Wang, J.R. Liu, and R. Yang: J. Appl. Crystallogr., 2018, vol. 51(4), pp. 1125–31.

L. Germain, N. Gey, and M. Humbert: Ultramicroscopy, 2007, vol. 107(12), pp. 1129–35.

C. Cayron, B. Artaud, and L. Briottet: Mater. Charact., 2006, vol. 57(4–5), pp. 386–401.

M.G. Glavicic, P.A. Kobryn, and S.L. Semiatin: Mater. Sci. Eng. A, 2004, vol. 385(1–2), pp. 372–76.

S. Hémery, J.C. Stinville, F. Wang, M.A. Charpagne, M.G. Emigh, T.M. Pollock, V. Valle: Acta Mater., 2021, vol. 219.

T. Furuhara, B. Poorganji, H. Abe, and T. Maki: JOM, 2007, vol. 59(1), pp. 64–67.

L. Li, M.Q. Li, and J. Luo: Acta Mater., 2015, vol. 94, pp. 36–45.

F. Warchomicka, C. Poletti, and M. Stockinger: Mater. Sci. Eng. A, 2011, vol. 528(28), pp. 8277–85.

L. Li, J. Luo, J.J. Yan, and M.Q. Li: J. Alloys Compd., 2015, vol. 622, pp. 174–83.

F.J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, 2nd ed. Elsevier, New York, 2004, pp. 333–78.

Y. Li, B. Gu, S. Jiang, Y. Liu, Z. Shi, J. Lin: Int. J. Plast., 2020, vol. 134.

S. Gourdet and F. Montheillet: Acta Mater., 2003, vol. 51(9), pp. 2685–99.

V. Yadav, N. Moelans, Y. Zhang, D. Juul Jensen: Acta Mater., 2021, vol. 221.

N. Moelans, B. Blanpain, and P. Wollants: Acta Mater., 2006, vol. 54(4), pp. 1175–84.

N. Moelans, B. Blanpain, and P. Wollants: Acta Mater., 2007, vol. 55(6), pp. 2173–82.

K. Chang, W. Feng, and L.Q. Chen: Acta Mater., 2009, vol. 57(17), pp. 5229–36.

K. Huang, K. Marthinsen, Q. Zhao, and R.E. Logé: Prog. Mater. Sci., 2018, vol. 92(17), pp. 284–359.

P. Vo, M. Jahazi, and S. Yue: Metall. Mater. Trans. A, 2008, vol. 39, pp. 2965–80.

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D. Juul Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, A.D. Rollett: Mater. Today, 1998, vol. 1 (2), pp. 14–15.

H. Jazaeri and F.J. Humphreys: Acta Mater., 2004, vol. 52(11), pp. 3239–250.

Acknowledgments

This work was supported by the Youth Innovation Promotion Association CAS (No. 2020193), CAS Project for Young Scientists in Basic Research (YSBR-025) and National Science and Technology Major Project (J2019-VI-0005-0119).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, Z.B., Zhang, B.H., Wang, Q.J. et al. Microtexture Evolution of Titanium Alloy During Hot Deformation: For Better Understanding the Role of Primary α Grains. Metall Mater Trans A 54, 2890–2902 (2023). https://doi.org/10.1007/s11661-023-07066-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07066-0