Abstract

We present two-dimensional numerical simulations of tilted lamellar growth patterns during directional solidification of nonfaceted binary eutectic alloys in the presence of an anisotropy of the free energy \(\gamma \) of the interphase boundaries in the solid. We used a dynamic boundary-integral (BI) method. The physical parameters were those of the transparent eutectic \(\mathrm CBr_4\)-\(\mathrm C_2Cl_6\) alloy. As in Ghosh et al. (Phys Rev E 91, 022407, 2015), the anisotropy of \(\gamma \) was described by a model function with tunable parameters. The lamellar-locking effect in the vicinity of a deep minimum of the interfacial energy was reproduced. For a weak anisotropy, the lamellar tilt angle \(\theta _t\) was shown to depend on the growth conditions. We systematically studied the influence of usual control parameters (pulling velocity, temperature gradient, lamellar spacing, alloy concentration) on the tilted-lamellar pattern. We identified experimentally accessible conditions under which \(\theta _t\) falls close to the theoretical prediction based on the so-called symmetric-pattern approximation. We finally simulated locked and weakly locked lamellar patterns and found empirically a good morphological matching with experimental observations during directional solidification of thin \(\mathrm CBr_4\)-\(\mathrm C_2Cl_6\) samples.

Similar content being viewed by others

References

J. Kwon, M.L. Bowers, M.C. Brandes, V. McCreary, I.M. Robertson, P. Sudaharshan Phani, H. Bei, Y.F. Gao, G.M. Pharr, E.P. George, and M.J. Millsa: Acta Mater., 2015, vol. 89, pp. 315–26.

J. Llorca and V. M. Orera: Progr. Mater. Sci., 51, 711-809 (2006).

J. Choi, A. A. Kulkarni, E. Hanson, D. Bacon-Brown, K. Thornton, and P. V. Braun: Adv. Optical Mater., 6, 1701316 (2018).

W. Kurz and D.J. Fisher: Fundamentals of Solidification, 4th ed., Trans Tech Publications Ltd, 1998.

J. A. Dantzig and M. Rappaz, Solidification, 2nd Edition, EPFL Press, Lausanne (2016).

S. Akamatsu and M. Plapp: Curr. Opin. Solid State Mater. Sci., 20, 46-54 (2016).

L. M. Hogan, R. W. Kraft, and F.D. Lemkey: Adv. Mater. Res., 5, 83-126 (1971).

R.W. Kraft: Trans. Metall. Soc. AIME, 224, 65-75 (1962).

S. K. Aramanda, S. Khanna, S. K. Salapaka, K. Chattopadhyay, and A. Choudhury: Metall. Mater. Trans. A, 51, 6387-6405 (2020).

K. A. Jackson and J. D. Hunt: Trans. Metall. Soc. AIME, 236, 1129-1142 (1966).

B. Caroli, C. Caroli, G. Faivre, and J. Mergy: J. Cryst. Growth, 118, 135-150 (1992).

S. Akamatsu, S. Bottin-Rousseau, M. Şerefoğlu, and G. Faivre: Acta Mater., 60, 3199-3205 (2012).

S. Akamatsu, S. Bottin-Rousseau, M. Şerefoğlu, and G. Faivre: Acta Mater., 60, 3206-3214 (2012).

S. Ghosh, A. Choudhury, M. Plapp, S. Bottin-Rousseau, G. Faivre, and S. Akamatsu: Phys. Rev. E, 91, 022407 (2015).

S. Bottin-Rousseau, O. Senninger, G. Faivre, and S. Akamatsu: Acta Mater., 150, 16-24 (2018).

Z. Tu, J. Zhou, L. Tong, and Z. Guo: J. Cryst. Growth, 532, 125439 (2020).

A. Karma and A. Sarkissian: Met. Trans. A, 27, 635-656 (1996).

J. Mergy, G. Faivre, C. Guthmann, and R. Mellet: J. Cryst. Growth, 13, 353-368 (1993).

M. Ginibre, S. Akamatsu, and G. Faivre: Phys. Rev. E, 56, 780-796 (1997).

S. Akamatsu, S. Bottin-Rousseau, M. Perrut, G. Faivre, V.T. Witusiewicz, and L. Sturz: J. Cryst. Growth, 299, 418-428 (2007).

K. Kassner and C. Misbah: Phys. Rev. A, 44, 6513-6532 (1991).

D.W. Hoffman and J.W. Cahn: Surf. Sci., 1972, vol. 31, pp. 368–88.

C. Herring: Phys. Rev., 82, 87-93 (1951).

R. Folch and M. Plapp: Phys. Rev. E, 72, 011602 (2005).

K.B. Kim, J. Liu, N. Marasli, and J.D. Hunt: Acta Metall. Mater., 1995, vol. 43, pp. 2143–47.

G. Faivre and J. Mergy: Phys. Rev. A, 45, 7320-7329 (1992).

V.T. Witusiewicz, U. Hecht, and S. Rex: J. Cryst. Growth, 372, 57-64 (2013).

R. Kokotin and U. Hecht: Comput. Mater. Sci., 86, 30-37 (2014).

S. Ghosh and M. Plapp: Acta Mater., 140, 140-148 (2017).

C. Zhua, Y. Koizumi, A. Chiba, K. Yuge, K. Kishida, and H. Inui: Intermetallics, 116, 106590 (2020).

K. D. Noubary, M. Kellner, P. Steinmetz, J. Hötzer, B. Nestler: Comput. Mater. Sci., 138, 403-411 (2017).

A. Lahiri, C. Tiwary, K. Chattopadhyay, and A. Choudhury: Comput. Mater. Sci., 130, 109-120 (2017).

M. Ignacio and M. Plapp: Phys. Rev. Materials, 3, 113402 (2019).

Z. Tu, J. Zhou, Y. Zhang, W. Li, and W. Yu: J. Cryst. Growth, 549, 125851 (2020).

A. Valance, C. Misbah, and D. Temkin: Phys. Rev. E, 48, 1924 (1993).

K. Kassner and C. Misbah: Phys. Rev. A, 45, 7372-7384 (1992).

Acknowledgments

We thank Mathis Plapp for insightful discussions. This work was financially funded by M.Era-net Grant ANPHASES no 187777.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted 23 April 2021; accepted 18 July 2021.

Appendices

Appendix A

In this Appendix, we propose a list of the symbols used in the text. In Table II, physical parameters are listed. Table III provides a list of dimensionless variables and symbols.

Appendix B

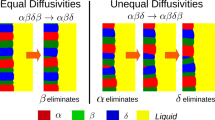

In this Appendix, we were aiming to show useful details related to the anisotropy effect that was simulated in Figures 9 (Figure 11) and 10 (Figure 12) in Section IV–E. We recall that the anisotropic surface energy of the interphase boundary is written in the form of \(\gamma (\theta ) = \gamma _0 [1-a_c(\theta -\theta _R)]\), with \(\theta _R\) setting the angular orientation of the eutectic grain (see Eq. [14]). The model anisotropy function \(a_c\) is taken in the form \(a_c(\theta ) = \epsilon _g \exp \left[ -(\theta /w_g)^2\right] - \epsilon _2\cos 2\theta - \epsilon _4\cos 4\theta \) (see Eq. [15]). The relevant values of the various coefficients are recalled in the captions of Figures 11 and 12 for convenience.

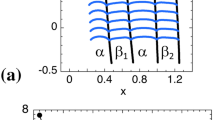

(a) Wulff shape (green line) and \(\gamma \) plot (blue line) of the anisotropy function used for the simulations shown in Fig. 9. The graph is rotated by an angle equal to the relevant \(\theta _R\) value. (b) Tilt angle \(\theta _{sp}\) in the sp approximation for the same anisotropy function. (c) Detail of the experimental microstructure. Red dots: locked (label L) and floating (label F) interphase boundaries. The L and F points are both close to an intersect in the Wulff shape. The arrow (label U) in (a) and (b) designates the unstable branch. Coefficients in the anisotropy function: \(\epsilon _g=0.2\), \(w_g=0.1\), \(\epsilon _2=0.104\), \(\epsilon _4=0.02208\), and \(\theta _R=51^o\). Color online

(a) Wulff shape (green line) and \(\gamma \) plot (blue line) of the anisotropy function used for the simulations shown in Fig. 10. The graph is rotated by an angle equal to the relevant \(\theta _R\) value. (b) Tilt angle \(\theta _{sp}\) in the sp approximation for the same anisotropy function. (c) Details of the experimental microstructure. Red dots: locked (label L) and floating (label F) interphase boundaries. The arrow (label U) in (a) and (b) designates the unstable branch. Coefficients in the anisotropy function: \(\epsilon _g=0.2\), \(w_g=0.005\), \(\epsilon _2=0.2\), \(\epsilon _4=0.06\), and \(\theta _R=35.0^o\). Color online

Rights and permissions

About this article

Cite this article

Akamatsu, S., Bottin-Rousseau, S. Numerical Simulations of Locked Lamellar Eutectic Growth Patterns. Metall Mater Trans A 52, 4533–4545 (2021). https://doi.org/10.1007/s11661-021-06407-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06407-1