Abstract

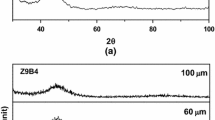

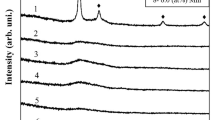

In this study, the glass-forming ability (GFA), structure and microstructure of (Fe1−xNix)88Zr7B4Cu1 (x = 0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8 and 1.0) alloys, in both the as-melt spun and heat-treated conditions, have been investigated. Almost complete amorphization was observed only for x = 0, 0.4 and 0.5 alloys at the highest melt spun wheel speed of 47 m/s. At lower wheel speeds all alloys are partially crystalline. The crystalline phases are bcc solid solution (bcc-SS) up to a composition of x = 0.2 and fcc solid solution (fcc-SS) for x = 0.6 and above. At a melt spun wheel speed of 47 m/s, the alloy with the composition of x = 0.3 is almost amorphous, along with traces of both bcc and fcc phases. Ribbons annealed at 450 °C/500 °C (after the first exothermic peak observed in DSC result) exhibit bcc-SS at low Ni concentration (up to x = 0.4) and fcc-SS at higher Ni concentration (x = 0.6 and beyond), whereas x = 0.5 ribbon shows the formation of both bcc-SS and fcc-SS. Ribbons annealed at 620 °C/750 °C (after the second exothermic peak observed in DSC results) exhibit Fe3Zr at low Ni concentration up to x = 0.3 and Ni5Zr from x = 0.4. The crystalline phases form during melt spinning are in the form of dendrites of submicron size, whereas the precipitated phases formed during annealing are nanocrystalline in nature. Thermodynamic modeling was carried out to understand the GFA and phase formation, which are in conformity with the experimental observations.

Similar content being viewed by others

References

G. Herzer: IEEE Trans. Magn., 1989, Vol. 25, pp. 3327–3329.

Y. Yosizawa, S. Oguma and K. Yamauchi: J. Appl. Phys., 1998, Vol. 64, pp. 6044–6046.

K. Suzuki, A. Makino, N. Kataoka, A. Inoue and T. Masumoto: Mater. Trans. JIM, 1991, Vol. 32, pp. 93–102.

M.A. Willard, M.Q. Huang, D.E. Laughlin, M.E. McHenry, J.O. Cross, V.G. Harris: J. Appl. Phys. 1999, Vol. 85, pp. 4421–4423.

M.E. McHenry, M.A. Willard and D.E. Laughlin:, Prog. Mater. Sci., 1999, Vol. 44, pp. 291–433.

Y.J. Liu, I.T.H. Chang and M.R. Lees: Scripta Mater., 2001, Vol 44, pp. 2729-2734.

Y.J. Liu, I.T.H. Chang and M.R. Lees: Mater. Sci. Eng. A, 304, 992–996 (2016)

W. Qin, Y.F. Zhang, F. Xu, Y.W. Du and Y.J. Wu: J. Alloys Comp., 2004, Vol. 372, pp. 1-6.

N. Aronhime, V. DeGeorge, V. Keylin, P. Ohodnicki, and M. E. McHenry: J. Materials., 2017, 69(11), 2164–2170.

N. Aronhime, E. Zhoglin, V. Keylin, X. Jin, P. Ohodnicki, and M. E. McHenry:Scripta Mat. 2018, Vol. 120C, pp. 133-137.

P. R. Ohodnicki, N. C. Cates, D. E. Laughlin, M. E. McHenry, and M. Widom. Phys. Rev. B 2008, Vol. 78, pp. 144414-144427.

J. Long, P. R. Ohodnicki, D. E Laughlin, M. E. McHenry, T. Ohkubo, and K. Hono. J. Appl. Phys., 2007, 101, 09N114-116.

N. Aronhime, P. R. Ohodnicki and M. E. McHenry, ScriptaMateriala, 2019, Vol. 169, pp 9-13.

J.J. Ipus, P. Herre, P.R. Ohodnicki, and M.E. McHenry: J. Appl. Phys., 2012, vol. 111, art. no. 07A323.

H. Ucar, J. J. Ipus, V. Franco, M. E. McHenry, D. E. Laughlin, J. Metals, 2012, Vol. 64, pp 772-781.

D. ArvindhaBabu, B. Majumdar, R. Sarkar, B.S. Murty and K. Chattopadhyay: Metall. Mater. Trans. A, 2016, 47, 560-571.

D.M. Zhu, K. Raviprasad, K. Suzuki and S.P. Ringer: J. Phys. D: Appl. Phys., 2004, Vol. 37, pp. 645-652.

M. Srinivas, B. Majumdar, G. Phanikumar, and D. Akhtar: Metal. Mater. Trans. B, 2011, Vol. 42B, pp. 370-379.

J.B. Nelson, and D.P. Riley: Proc. Phys. Soc. 1945, 57, 160.

D. ArvindhaBabu, B. Majumdar, R. Sarkar, and D. Akhtar: J. Phys. D: Appl. Phys., 2008, Vol. 41, pp. 195002-195008.

A.K. Niessen, F.R. Deboer, R. Boom, P.F. Dechatel, W.C.M. Mattens and A.R. Miedema: Calphad, 1983, 7, 51-70.

Y. Nakamura: IEEE Trans. Magn. 1976, 4, 278-291.

Acknowledgments

This work was supported by Defence Research and Development Organization (DRDO), New Delhi, India. The authors thank Dr. RP Mathur, Group Head, Advanced Magnetics Group, DMRL, and Dr. G Madhusudhan Reddy, Director, DMRL, for continued support and permission to publish this work.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 27, 2020 and accepted October 26, 2020.

Rights and permissions

About this article

Cite this article

Arvindha Babu, D., Majumdar, B., Sarkar, R. et al. Phase Stability of Rapidly Solidified (Fe1−xNix)88Zr7B4Cu1 Ribbons. Metall Mater Trans A 52, 560–573 (2021). https://doi.org/10.1007/s11661-020-06086-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-06086-4