Abstract

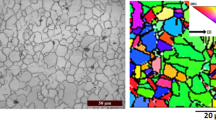

In this work, the effect of welding temperature on material flow during friction stir welding (FSW) of AZ31 magnesium alloy was examined. To this end, FSW was conducted in the temperature range of 0.65-0.85 Tm (Tm is the melting point) and sample-scale EBSD mapping was employed to characterize texture distribution. Despite that the low-temperature welds contained macro-scale defects (which presumably affected material flow), several important observations were made. In the entire temperature range, the global material motion was shown to consist of two principal components, viz. shoulder-induced flow and probe-induced flow. In some cases, however, a synergetic effect of these two constituents resulted in transitional orientation of macro-scale shear plane thus giving rise to a transitional material flow. During low-temperature FSW, the global material transportation was dominated by the probe. However, the contribution of the shoulder and transitional components was found to increase with welding temperature. This effect was attributed to the dominant role of the shoulder in generation of FSW heat. Above ~ 0.8 Tm, however, the transitional material flow was found to abruptly disappear. This result was associated with reduction of temperature sensitivity of flow stresses and the resulting equilibration of their distribution within the stir zone.

Similar content being viewed by others

Notes

Here and hereafter, a reader is referred to on-line version of this paper to see figures in color.

The textural data shown in these figures were derived from the regions numbered in Figures 5(b) and (c), respectively.

References

R.S. Mishra, Z.Y. Ma: Mater. Sci. Eng. R., 2005. Vol. 50A, pp. 1–78

R. Nandan, T. DebRoy, H.K.D.H. Bhadeshia: Progress Mater. Sci., 2008, vol. 53, pp. 980–1023

P.L. Threadgill, A.J. Leonard, H.R. Shercliff and P.J. Withers: Int. Mater. Rev., 2009, vol. 54, pp. 49-93

U.F.H.R. Suhuddin, S. Mironov, Y.S. Sato, H. Kokawa, C.-W. Lee: Acta Mater., 2009, vol. 57, pp. 5406-5418

S. Mironov, Q. Yang, H. Takahashi, I. Takahashi, K. Okamoto, Y.S. Sato, H. Kokawa: Metall. Mater. Trans A., 2010, vol. 41, pp. 1016-1024

R.W. Fonda and K.E. Knipling: Sci. Tech. Weld. Join., 2011, vol. 16, pp. 288-294

P.B. Prangnell, C.P. Heason: Acta Mater., 2005, vol. 53, pp. 3179-3192

R.W. Fonda, J.F. Bingert: Scripta Mater., 2007, vol. 57, pp. 1052-1055

Y.S. Sato, H. Kokawa, K. Ikeda, M. Enomoto, S. Jogan, T. Hashimoto: Metall. Mater. Trans. A, 2001, vol. 32, pp. 941-948

D.P. Field, T.W. Nelson, Y. Hovanski, K.V. Jata: Metall. Mater. Trans. A, 2001, vol. 32, pp. 2869-2877

A.P. Reynolds, E. Hood, W. Tang: Scripta Mater., 2005, vol. 52, pp. 491–494

T.U. Seidel, A.P. Reynolds: Metall. Mater. Trans. A, 2001, vol. 32, pp. 2879-2884

K.N. Krishnan: Mater. Sci. Eng. A, 2002, vol. 327, pp. 246-251

Y. Morisada, T. Imaizumi and H. Fujii: Sci. Technol. Weld. Join., 2015, vol. 20, pp. 130-137

Y. Morisada, T. Imaizumi and H. Fujii: Scripta Mater., 2015, vol. 106 (2015), pp. 57-60

T.U. Seidel, A.P. Reynolds: Sci. Technol. Weld. Join., 2003, vol. 8, pp. 175–183

R. Nandan, G.G. Roy, T.J. Lienert, T. DebRoy: Sci. Technol. Weld Join, 2006, vol. 11, pp. 526–537

H. Schmidt, T.L. Dickerson, J. Hattel: Acta Mater., 2006, vol. 54, pp. 1199–209

M. Guerra, C. Schmidt, J.C. McClure, L.E. Murr, A.C. Nunes: Mater. Character., 2002, vol. 49, pp. 95–101

R. Crawford, G. E. Cook, A. M. Strauss, D. A. Hartman and M. A. Stremler: Sci. Technol. Weld. Join., 2006, vol. 11, pp. 657–665

A.P. Reynolds: Sci. Technol. Weld. Join., 2000, vol. 5, pp. 120–124

S. Mironov, T. Onuma, Y.S. Sato, H. Kokawa: Acta Mater., 2015, vol. 100, pp. 301-312

D.P. Field: Ultramicroscopy, 1997, vol. 67, pp. 1-9

S.H.C. Park, Y.S. Sato, and H. Kokawa: Metall. Mater. Trans. A., 2003, vol. 34, pp. 987-994

W. Tang, X. Guo, J.C. McClure, L.E. Murr, A. Nunes: J. Mater. Proc. Manuf. Sci., 1998, vol. 7, pp. 163-172.

I.A. Maksoud, H. Ahmed, J. Rodel: Mater. Sci. Eng. A., 2009, vol. 504, pp. 40–48

J.A. Schneider and A.C. Nunes: Metall Mater. Trans. B, 2004, vol. 35, pp. 777-783

Y. Huang, Y. Wang, L. Wan, H. Liu, J. Shen, J.F. dos Santos, L. Zhou, and J. Feng: Int. J. Adv. Manuf. Technol., 2016, vol. 87, pp. 115-1123

M.M.Z. Ahmed, B.P. Wynne, W.M. Rainforth, A. Addison, J.P. Martin, and P.L. Threadgill: Metall. Mater. Trans. A, 2019, vol. 50, pp. 271-284

Y. Huang, Y. Xie, X. Meng, Z. Lv, J. Cao: J. Mater. Process. Technol., 2018, vol. 252, pp. 233-241

Conflict of Interest

No potential conflict of interest was reported by the authors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 4, 2018.

Rights and permissions

About this article

Cite this article

Mironov, S., Sato, Y.S. & Kokawa, H. Influence of Welding Temperature on Material Flow During Friction Stir Welding of AZ31 Magnesium Alloy. Metall Mater Trans A 50, 2798–2806 (2019). https://doi.org/10.1007/s11661-019-05194-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05194-0