Abstract

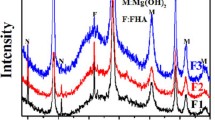

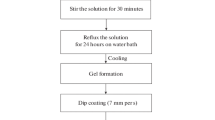

This work deals with the electrodeposition of calcium phosphate coatings on the surface of Fe-Mn-Si alloys which is designed for bone implant applications. Three different alloy compositions are considered (Fe-23Mn-5Si, Fe-26Mn-5Si and Fe-30Mn-5Si, all in wt pct). In order to explore the impact of hydrogen peroxide (H2O2) on the electrodeposition process, two different electrolytic solutions are studied, one that contains no H2O2 and the other that contains 9 vol pct H2O2. The physicochemical characterizations reveal that the electrodeposited coating is made of an apatite phase of low crystallinity with less porosity when hydrogen peroxide is added to the electrolyte solution. The corrosion measurements of the uncoated and coated alloys are also carried out during immersion in Hank’s solution at 310 K (37 °C), a physiological solution that simulates the inorganic composition of the body fluids. Interestingly, it was found that the manganese content in the alloy and the porosity of the coating both modify the corrosion behavior, i.e., the biodegradability of the Fe-Mn-Si alloy immersed in the physiological environment. Hence, the corrosion behavior of the calcium phosphate-coated Fe-Mn-Si alloys is tunable as a function of the experimental parameters used during the synthesis of the material.

Similar content being viewed by others

References

[1] Y.F. Zheng, X.N. Gu, and F. Witte: Mater. Sci. Eng. R, 2014, vol. 77, pp. 1-34.

[2] H. Li, Y. Zheng, and L. Qin: Prog. Nat. Sci., 2014, vol. 24, pp. 414-22.

[3] M. Niinomi: Metall. Mater. Trans. A, 2002, vol. 33, pp. 477-86.

[4] H. Hermawan, D. Dubé, and D. Mantovani: Acta Biomater., 2010, vol. 6, pp. 1693-7.

[5] M. Schinhammer, A.C. Hänzi, J.F. Löffler, and P.J. Uggowitzer: Acta Biomater., 2010, vol. 6, pp. 1705-13.

[6] A. Francis, Y. Yang, S. Virtanen, and A.R. Boccaccini: J. Mater. Sci., 2015, vol. 26, pp. 138-53.

[7] C.H. Yang, H.C. Lin, K.M. Lin, and H.K. Tsai: Mater. Sc. Eng. A, 2008, vol. 497, pp. 445-50.

[8] R. Drevet, Y. Zhukova, P. Malikova, S Dubinskiy, A. Korotitskiy, Y. Pustov, and S. Prokoshkin: Metall. Mater. Trans. A, 2018, vol. 49, pp. 1006-13.

[9] T. Niendorf, F. Brenne, P. Hoyer, D. Schwarze, M. Schaper, R. Grothe, M. Wiesener, G. Grundmeier, and H.J. Maier: Metall. Mater. Trans. A, 2015, vol. 46, pp. 2829-33.

[10] F. Witte: Acta Biomater., 2010, 6, pp. 1680-92.

[11] Y. Chen, Z. Xu, C. Smith, and J. Sankar: Acta Biomater., 2014, vol. 10, pp. 4561-73.

[12] H. Hermawan, D. Dubé, and D. Mantovani: J. Biomed. Mater. Res., 2010, vol. 93A, pp. 1-11.

[13] M. Kaya and O. Cakmak: Metall. Mater. Trans. A, 2016, vol. 47, pp. 1499-503.

[14] Y.P. Feng, N. Gaztelumendi, J. Fornell, H.Y. Zhang, P. Solsona, M.D. Baró, S. Suriñach, E. Ibáñez, L. Barrios, E. Pellicer, C. Nogués, and J. Sort: J. Alloy. Compd, 2017, vol. 724, pp. 1046-56.

[15] Y.P. Feng, A. Blanquer, J. Fornell, H. Zhang, P. Solsona, M.D. Baró, S. Suriñach, E. Ibáñez, E. García-Lecina, X. Wei, R. Li, L. Barrios, E. Pellicer, C. Nogués, and J. Sort: J. Mater. Chem. B, 2016, vol. 4, pp. 6402-12.

[16] S.R. Paital, and N.B. Dahotre: Mater. Sci. Eng. R, 2009, vol. 66, pp. 1-70.

[17] S.V. Dorozhkin: Mater. Sci. Eng. C, 2015, vol. 55, pp. 272-326.

[18] R.A. Surmenev, M.A. Surmeneva, and A.A. Ivanova: Acta Biomater., 2014, vol. 10, pp. 557-79.

[19] R.B. Heimann: Surf. Coat. Technol., 2006, vol. 201, pp. 2012-9.

[20] C. Domínguez-Trujillo, E. Peón, E. Chicardi, H. Pérez, J.A. Rodríguez-Ortiz, J.J. Pavón, J. García-Couce, J.C. Galván, F. García-Moreno, and Y. Torres: Surf. Coat. Technol., 2018, vol. 333, pp. 158-62.

[21] R.A. Ismail, E.T. Salim, and W.K. Hamoudi: Mater. Sci. Eng. C, 2013, vol. 33, pp. 47-52.

[22] M. Farrokhi-Rad: Surf. Coat. Technol., 2017, vol. 329, pp. 155-62.

[23] M. Ibrahim Coskun, I.H. Karahan, Y. Yücel, and T.D. Golden: Surf. Coat. Technol., 2016, vol. 301, pp. 42-53.

[24] J.Fornell, Y.P.Feng, E.Pellicer, S.Suriñach, M.D.Baró, and J.Sort: J. Alloy. Compd., 2017, vol. 729, pp. 231-9.

[25] R. Drevet, H. Benhayoune, L. Wortham, S. Potiron, J. Douglade, and D. Laurent-Maquin: Mater. Charact., 2010, vol. 61, pp. 786-95.

[26] F.A. Azem, T.K. Delice, G. Ungan, and A. Cakir: Mater. Sci. Eng. C, 2016, vol. 68, pp. 681-6.

R. Drevet and H. Benhayoune: Calcium Phosphate: Structure, Synthesis, Properties, and Applications, R.B. Heimann (Eds.), Nova Science Publishers Inc, New York, 2012, pp. 231-52.

[28] M.C. Kuo, and S.K. Yen: Mater. Sci. Eng. C, 2002, vol. 20, pp. 153-60.

[29] N. Eliaz, and T.M. Sridh: Cryst. Growth Des., 2008, vol. 8, pp. 3965-77.

[30] J.M. Zhang, C.J. Lin, Z.D. Feng, and Z.W. Tian: J. Electroanal. Chem., 1998, vol. 452, pp. 235-40.

[31] E.A. Abdel-Aal, D. Dietrich, S. Steinhaeuser, and B. Wielage: Surf. Coat. Technol., 2008, vol. 202, pp. 5895-900.

[32] N. Dumelié, H. Benhayoune, C. Rousse-Bertrand, S. Bouthors, A. Perchet, L. Wortham, J. Douglade, D. Laurent-Maquin, and G. Balossier: Thin Solid Films, 2005, vol. 492, pp. 131-9.

[33] I. Zhitomirsky: Adv. Colloid Interface Sci, 2002, vol. 97, pp. 279-317.

[34] N. Eliaz and M. Eliyahu: J. Biomed. Mater. Res. A, 2007, vol. 80, pp. 621-34.

[35] R. Drevet, A. Viteaux, J. C. Maurin, and H. Benhayoune: RSC Adv., 2013, vol. 3, pp. 11148-54.

[36] S. Stanciu, A. Ursanu, L.C. Trinca, T.A. Elena, S. Carmen, C. Munteanu, N. Cimpoesu, D. Acatrinei, E.V. Sindilar, T. Stanciu, M. Fantanariu, and L. Topliceanu: Environ. Eng. Manag. J., 2016, vol. 15, pp. 973-80.

[37] R.I.M. Asri, W.S.W. Harun, M. Samykano, N.A.C. Lah, S.A.C. Ghani, F. Tarlochan, and M.R. Raza: Mater. Sci. Eng. C, 2017, vol. 77, pp. 1261-74.

[38] U. Kamachimudali, T.M. Sridhar, and B. Raj: Sadhana-Acad. Proc. Eng. Sci., 2003, vol. 28, pp. 601-37.

[39] R. Singh, and N.B. Dahotre: J. Mater. Sci. Mater. Med., 2007, vol. 18, pp. 725-51.

Acknowledgments

The present work was carried out with the financial support of the Ministry of Education and Science of the Russian Federation, in the framework of the Increase Competitiveness Program of NUST “MISIS” (Grant No. К4-2016-57). The authors thank Dr. E. Bazanova, NUST “MISiS” Director of Academic Writing Office, and Dr. M.F. Ijaz for their critical reading of the manuscript and some helpful suggestions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 20, 2018.

Rights and permissions

About this article

Cite this article

Drevet, R., Zhukova, Y., Kadirov, P. et al. Tunable Corrosion Behavior of Calcium Phosphate Coated Fe-Mn-Si Alloys for Bone Implant Applications. Metall Mater Trans A 49, 6553–6560 (2018). https://doi.org/10.1007/s11661-018-4907-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4907-6