Abstract

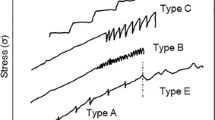

Eight medium manganese steels ranging from 10 to 15 wt pct Mn have been produced with varying levels of aluminum, silicon, and carbon to create steels with varying TRIP (transformation-induced plasticity) character. Alloy chemistries were formulated to produce a range of intrinsic stacking fault energies (ISFE) from − 2.2 to 13.3 mJ/m2 when calculated at room temperature for an austenitic microstructure having the nominal alloy composition. Two-stage TRIP behavior was documented when the ISFE of the γ-austenite phase was 10.5 mJ/m2 or less, whereas an ISFE of 11.9 mJ/m2 or greater exhibited TWIP (twin-induced plasticity) with single-stage TRIP to form α-martensite. Properties were measured in both hot band (hot rolled) and batch annealed (hot rolled, cold rolled, and annealed) conditions. Hot band properties were influenced by the Si/Al ratio and this dependence was related to incomplete recovery during hot working for alloys with Si/Al ratios greater than one. Batch annealing was conducted at 873 K (600 °C) for 20 hours to produce ultrafine-grained microstructures with mean free slip distances less than 1 μm. Batch-annealed materials were found to exhibit a Hall–Petch dependence of the yield strength upon the mean free slip distance measured in the polyphase microstructure. Ultimate tensile strengths ranged from 1450 to 1060 MPa with total elongations of 27 to 43 pct. Tensile ductility was shown to be proportional to the sum of the products of volume fraction transformed times the volume change associated for each martensitic transformation. An empirical relationship based upon the nominal chemistry was derived for the ultimate tensile strength and elongation to failure for these batch-annealed steels. Two additional alloys were produced based upon the developed understanding of these two-stage TRIP steels and tensile strengths of 1150 MPa with 58 pct total elongation and 1400 MPa and 32 pct ductility were achieved.

Similar content being viewed by others

References

Q. Li, X. Huang, and W. Huang: Met Sci. Eng., 2016, vol. 662, pp. 129-35.

E.J. Seo, L. C, Y. Estrin, and B.C. De Cooman: Acta Mater., 2016, vol. 113, pp. 124-39

L. Cho, E.J. Seo, and B.C. De Cooman: Scripta Materialia, 2016, vol. 123, pp. 69-72

T. Tschiyama, T. Inoe, J. Tobata, D. Akami, and S. Takaki: Scripta Mat. 2016, vol. 122, pp. 36-39

D.-W. Suh, S.-J. Park, T.-H. Lee, C.-S. Oh, and S.-J. Kim: Met Trans A, 2010, vol. 41A, pp. 397–408

D.-W. Suh, J.-H. Ryu, M.-S. Joo, H.-S. Yang, H.K.D.H. Bhadeshia: Met Trans A, 2013, vol. 44A, pp. 286–93

J. Shi, X. Sun, M. Wang, W. Hui, H. Dong, and W. Cao: Scripta Mat, 2010, vol. 63, pp. 815-18

Z.H. Cai, H. Ding, R.D.Misra, and Z.Y. Ying: Acta Materialia, 2015, vol. 84, pp. 229-36

R. Zhang, W.Q. Ca, Z.J. Peng, J. Shi, H. Dong, and C.X. Huang: Mater. Sci. & Eng. A, 2013, vol. 583, pp. 84-88

R. Skolly, ArcelorMittal personal communication.

Y. Zhang, L. Wang, K. O. Findley, and J. Speer: Met Trans. A, 2017, vol. 48A, pp. 2140-49

H. Luo, H. Dong, and M. Huang: Mater. & Design, 2015, vol. 83, pp.42-48

S. Lee, W. Woo, and B.C. De Cooman: Met. Trans A, 2016, vol. 47A, pp. 2125-40

G. Frommeyer, U. Brux, and P. Neumann: ISJ Inter. 2003, vol. 43, pp. 438-46

L. Remy, and A. Pineau: Mater. Sci and Eng. 1976, vol. 26 pp. 123-32

S. Allain, J.P. Chateau, and O. Bouaziz: Mater Sci and Eng. 2004, vol. 387, pp. 143-47

T.H. Lee, E. Shin, C.S. Oh, H.Y. Ha, and S.J. Kim: Acta Mater. 2010, vol. 58, 3173-86

H. Song, S.S. Sohn, J-H Kwak, B-J lee, and S. Lee: Met Trans A, 2016, vol. 47A, pp.2674-85

O. Grässel, L. Krüger, G. Frommeyer, and L.W. Meyer: International Journal of Plasticity, 2000, vol. 16, pp. 1391-1409

B.C. De Cooman, P. Gibbs, S. Lee, and D.K. Matlock: Met Trans A, 2013, vol. 44A, pp. 2563-72

D.M. Field and D.C. Van Aken: Metall. Mater. Trans. A, 2018, vol. 49A, pp. 1152–66

S.T. Pisarik, D.C. Van Aken, K. Limmer, and J.E. Medvedeva: AISTech 2014 Proceedings, 2014, vol. III, pp. 3013–23

S.K. Huang, Y.H. Wen, N.Li, J.Teng, S.Ding, Y.G. Xu: Mater Characterization vol.59, 2008, pp.681-87

S. Shin, M. Kwon, W. Cho, I. S. Suh, and B.C. De Cooman: Mater. Sci. & Eng. 2017, vol. 683, pp. 187-94

M.C. McGrath, D.C. Van Aken, N.I. Medvedeva, and J.E. Medvedeva: Metall. Mater. Trans. A, Vol. 44A, 2013, pp. 4634-43.

X.-S. Yang, S. Sun, H.-H. Ruan, S.-Q. Shi, and T.-Y. Zhang: Acta Mater., 2017, vol. 136, pp. 347–54

D.C. Van Aken, S.T. Pisarik, and M.C. McGrath: Proceedings of the International Symposium on New Developments in Advanced High-Strength Steels, Vail, Colorado, 2013, pp. 119–29.

D. M. Field, and D.C. Van Aken: Met Trans A., (2016) Vol. 47A pp.1912-17

N.I. Medvedeva, M.S. Park, D.C. Van Aken, and J.E. Medvedeva: J. Alloys Compd., Vol. 582, 2014, pp. 475–82

K.R. Limmer, J.E. Medvedeva, D.C. Van Aken and N.I. Medvedeva: Comput. Mater. Sci., 2015, vol. 99, pp. 253–55

S.T. Pisarik and D.C. Van Aken: Met Trans A., Vol. 47A 2016 pp1009-1018

D.M. Field, D.S. Baker, and D.C. Van Aken: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 2150–63

P.P. Suikkanen, V.T.E. Lang, M.C.Somani, D.A. Prter, and L.P. Karjalainen: ISIJ International, 2012, vol. 52, pp. 471-76

Z, Li-Juan, W. Di, and Z. Xian-ming: Jour. Iron and Steel research international, 2007, vol. 14, pp. 61-65

L.J. Zhu, D. Wu, X.M. Zhao: Acta Metall. 2008 vol. 21, pp. 163-68

M.C. Somani, L.P. Karjalainenm, D.A. Porter, and R.A. Morgridge: Proceedings of International Conference on Thermomechanical Processing Mechanics: Microstructures and Controls, University of Sheffield, Sheffield GB, (2003), 436.

S.F. Medina, and J. E. Mancilla: ISIJ Int. 1996, vol. 36, pp.1036-1070

S.F. Medina, and A. Quispe: ISIJ Int. 2001, vol. 41, pp.774-80

S-J. Lee, J. Kim, S.N. Kane, and B.C. De Cooman: Acta Materialia, 2011, vol. 59, pp.6809-19

S.J. Lee, S.W. Lee, B.C. De Cooman: Int. J. Mater. Res., 2013, vol. 104, pp. 423–29.

G.B. Olson, M. Cohen: Met Trans A Vol 7 1976 pp. 1897-1904

ASTM E 8/E 8M-08, Standard Test Methods for Tension Testing of Metallic Materials

S. Martin, C. Ullrich, D. Simek, U. Martin, and D. Rafaja: J. Appl. Crystallogr., 2011, vol. 44, pp. 779-87

N. Stanford and D.P. Dunne: Acta Materialia, 2010, Vol. 58, pp.6752-62

S. T. Pisarik, and D. C. Van Aken: Met Trans A., 2014, vol. 45, pp. 3173-78

M. Papa Rao, V. Subramanya Sarma, and S. Sankaran: Met. Trans. A 2014, vol 45A pp. 5313–17

M. Papa Rao, V. Subramanya Sarma, and S. Sankaran: Mater. Sci. & Eng. A 2013, vol. 568 pp. 171–75

O. Saray, G. Purcek, I. Karaman, H. Maier: Met Trans A 2012, vol. 43A. 4320–30

V.S.A. Challa, R.D.K. Misra, M.C. Comani and Z.D. Wang: Mater. Sci. & Eng 2016 vol. 661 pp.51–60

Y. Son, Y.K. Lee, K.-T. Park, C. S. Lee, and D. H. Shin: Acta Mater. 2005, vol. 53, pp. 3125–34

M. Calcagnotto, Y. Adachi, D. Ponge, and D. Raabe: Acta Meter. 2011, vol. 59 pp. 658–70

D. H. Shin, and K-T. Park: Mater. Sci. & Eng. A 2005, vol. 410-411, pp. 299-302

M. Calcagnotto, D. Ponge, E. Demir, and D. Raabe: Mater. Sci. & Eng. A 2010 vol. 527, pp. 2738-46

R.D.K. Misra, P.K.C. Vankatsurya, M.C. Somani, and L.P. Karjalinen: Met Trans A, 2012, vol. 43A, pp. 5286-97

P.J. Gibbs, E. De Moor, M.J. Merwin, B. Clausen, J.G. Speer, and D.K. Matlock: Met Trans A, 2011, vol. 42A, pp. 3691-3701

G. Dini, A. Najafizadeh, R. Ueji, and S.M. Monir-Vaghefi: Materials Letters, 2010, vol. 64, pp. 15-18

S. Rajasekhara, P.J. Ferreira, L.P. Karjalainenm and A. Kyröläinen: Met Trans A. 2007, vol. 38A, pp. 1202–1210

A. Rohatgi, K.S., Vecchio, and G.T. Gray III: Met. Trans. A, 2001, vol. 32A, pp. 135–45

D.J. Branagan, C.S. Parsons, T.V. Machrowicz, A.E. Frerichs, B.E. Meacham, S. Cheng, and A.V. Sergueeva 2016, Launch of a New Class of 3 rd Generation Cold Formable AHSS [PowerPoint slide 15 & 16]

Acknowledgments

This work was supported by the Peaslee Steel Manufacturing Research Center (PSMRC). Companies directly involved in this work include AK Steel, ArcelorMittal, Nucor Steel, and U. S. Steel. The FEI Helios NanoLab dual beam FIB was obtained with a Major Research Instrumentation Grant from the National Science Foundation under Contract DMR-0723128. The FEI Tecnai F20 scanning/transmission electron microscope was obtained through a major research instrumentation Grant from the National Science Foundation under Contract DMR-0922851. The authors also acknowledge the support of the Materials Research Center and in particular Dr. Clarissa Wisner for training on the SEM as well as Dr. Eric Bohannan for performing the XRD work. Special thanks are also extended to Dr. Narayan Pottore and Dr. Bernard Chukwulebe at ArcelorMittal, Todd Link from U.S. Steel, Eric Gallo at Nucor, and Dr. Luis Garza from AK Steel for their discussion and guidance on the engineering requirements for future 3rd generation advanced high-strength steels.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted date January 16, 2018.

Rights and permissions

About this article

Cite this article

Field, D.M., Qing, J. & Van Aken, D.C. Chemistry and Properties of Medium-Mn Two-Stage TRIP Steels. Metall Mater Trans A 49, 4615–4632 (2018). https://doi.org/10.1007/s11661-018-4798-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4798-6