Abstract

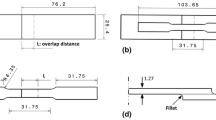

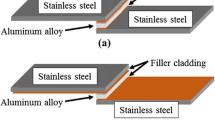

The high-cycle fatigue performance and crack growth pattern of transient liquid phase-brazed joints in a nickel-based superalloy Inconel 625 were studied. Assemblies with different geometries and types of overlaps were vacuum-brazed using the brazing paste Palnicro-36M in conditions such as to generate eutectic-free joints. This optimal microstructure provides the brazed assemblies with static mechanical strength corresponding to that of the base metal. However, eutectic micro-constituents were observed in the fillet region of the brazed assembly due to an incomplete isothermal solidification within this large volume of filler metal. The fatigue performance increased significantly with the overlap distance for single-lap joints, and the best performance was found for double-lap joints. It was demonstrated that these apparent changes in fatigue properties according to the specimen geometry can be rationalized when looking at the fatigue data as a function of the local stress state at the fillet radii. Fatigue cracks were nucleated from brittle eutectic phases located at the surface of the fillet region. Their propagation occurred through the bimodal microstructure of fillet and the diffusion region to reach the base metal. High levels of crack path tortuosity were observed, suggesting that the ductile phases found in the microstructure may act as a potential crack stopper. The fillet region must be considered as the critical region of a brazed assembly for fatigue applications.

Similar content being viewed by others

References

J.R. Davis: Heat-resistant materials, ASM International, Materials Park, OH, 1997, pp. 1-592.

N. Sheng, X. Hu, J. Liu, T. Jin, X. Sun, and Z. Hu: Metall. Mater. Trans. A, 2015, 46, pp. 1670-1677.

R. Bakhtiari, and A. Ekrami: Mater. Charact., 2012, 66, pp. 38-45.

D.S. Duvall, W.A. Owczarski, and D.F. Paulonis: Weld. J., 1974, 53, pp. 203-214.

W.F. Gale, and S.V. Orel: Metall. Mater. Trans. A, 1996, 27A, pp. 1925-1931.

J. Ruiz-Vargas, N. Siredey-Schwaller, N. Gey, P. Bocher, and A. Hazotte: J. Mater. Process. Technol., 2013, 213, pp. 20-29.

A. Sakamoto, C. Fujiwara, T. Hattori, and S. Sakai: Weld. J., 1989, 68, pp. 63-71.

Y. Zhishui, L. Ruifeng, and S. Kun: Appl. Mech. and Mater., 2012, 236-237, pp. 26-30.

A.T. Egbewande, C. Chukwukaeme, and O.A. Ojo: Mater. Charact., 2008, 59, pp. 1051-1058.

O.J. Adebajo, and O.A. Ojo: Metall. Mater. Trans. A, 2017, 48, pp. 26-33.

V. Jalilvand, H. Omidvar, H.R. Shakeri, and M.R. Rahimipour: Mater. Charact., 2013, 75, pp. 20-28.

L.M. Suave, J. Cormier, P. Villechaise, A. Soula, Z. Hervier, D. Bertheau and J. Laigo: Metall. Mater. Trans. A, 2014, 45, pp. 2963-2982.

L.M. Suave, J. Cormier, D. Bertheau, P. Villechaise, A. Soula, Z. Hervier and F. Hamon: Mater. Sci. Eng. A, 2016, 650, pp. 161-170.

M. Pouranvari, A. Ekrami, and A.H. Kokabi: Mater. Sci. Technol., 2014, 30, pp. 109-115.

C.Y. Su, W.C. Lih, C.P. Chou, and H.C. Tsai: J. Mater. Process. Technol., 2001, 115, pp. 326-332.

S. Neumeier, M. Dinkel, F. Pyczak, and M. Goken: Mater. Sci. Eng. A, 2011, 528, pp. 815-822.

L.O. Osoba, and O.A. Ojo: Metal. Mater. Trans. A, 2013, 44, pp. 4020-4024.

X. Yang, C. Dong, D. Shi, and L. Zhang: Mater. Sci. Eng., A, 2011, 528, pp. 7005-7011.

W.A. Demo, S. Ferrigno, D. Budinger, and E. Huron: Superalloys 2000 (9th International Symposium) Champion, Pennsylvania, 2000, pp. 713–20.

D. Shi, C. Dong, X. Yang, Y. Sun, J. Wang, and J. Liu: Mater. Des., 2013, 45, pp. 643-652.

Y.H. Kim, I.H. Kim, and C.S. Kim: Key Eng. Mater., 2005, 297-300, pp. 2876-2882.

J.D. Liu, T. Jin, N.R. Zhao, Z.H. Wang, X.F. Sun, H.R. Guan, and Z.Q. Hu: Mater. Charact., 2008, 59, pp. 68-73.

S. Steuer, and R.F. Singer: Metall. Mater. Trans. A, 2014, 45, pp. 3545-3553.

Metallic Materials and Elements for Aerospace Vehicle Structures, U.S. Department of Defense, 1998.

Technical bulletin Inconel alloy 625, Special Metals Corporation, pp. 1–18.

The AWS Brazing Handbook, 5th ed., American Welding Society (AWS), 2007, pp. 1–704.

D. Turner, Évolution microstructurale des joints brasés sur l’inconel 718 avec les alliages BNi-2 et PALNICRO 36M, Master Thesis, École de technologie supérieure, 2005.

J. Ruiz-Vargas, Étude des mécanismes de formation des microstructures lors du brasage isotherme de superalliages à base de nickel, PhD thesis, École de technologie supérieure, 2014.

J. Chen, V. Demers, E.-L. Cadotte, D. Turner, and P. Bocher: J. Mater. Eng. Perform., 2016, 26, pp. 547–553.

E. Lugscheider, H. Reimann, and O. Knotek: Weld. J., 1977, 56, pp. 189-192.

D.K. Wang, H.C. Wu, R.K. Shiue, and C. Chen: Adv. Mater. Res., 2008, 51, pp. 71-78.

S.D. Nelson, S. Liu, S. Kottilingam, and J.C. Madeni: Weld. in the World, 2014, 58, pp. 593-600.

N.C. Sheng, J.D. Liu, T. Jin, X.F. Sun, and Z.Q. Hu: Metall. Mater. Trans. A, 2013, 44, pp. 1793-1804.

Acknowledgments

The authors acknowledge the Natural Sciences and Engineering Research Council of Canada (NSERC), the Center for Research and Innovation in Aerospace in Quebec (CRIAQ), Pratt & Whitney Canada, and Turbomeca Canada under MANU-405 for financial support for this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 17, 2017.

Rights and permissions

About this article

Cite this article

Chen, J., Demers, V., Turner, D.P. et al. Experimental Investigation on High-Cycle Fatigue of Inconel 625 Superalloy Brazed Joints. Metall Mater Trans A 49, 1244–1253 (2018). https://doi.org/10.1007/s11661-018-4474-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4474-x