Abstract

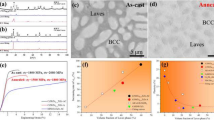

A novel refractory CoCrMoNbTi0.4 high-entropy alloy (HEA) was prepared via vacuum arc melting. After annealing treatment at different temperatures, the microstructure evolution, phase stability, and mechanical properties of the alloy were investigated. The alloy was composed of two primary body-centered cubic structures (BCC1 and BCC2) and a small amount of (Co, Cr)2Nb-type Laves phase under different annealing conditions. The microhardness and compressive strength of the heat-treated alloy was significantly enhanced by the solid-solution strengthening of the BCC phase matrix and newborn Laves phase. Especially, the alloy annealed at 1473 K (1200 °C) achieved the maximum hardness and compressive strength values of 959 ± 2 HV0.5 and 1790 MPa, respectively, owing to the enhanced volume fraction of the dispersed Laves phase. In particular, the HEAs exhibited promising high-temperature mechanical performance, when heated to an elevated temperature of 1473 K (1200 °C), with a compressive fracture strength higher than 580 MPa without fracture at a strain of more than 20 pct. This study suggests that the present refractory HEAs have immense potential for engineering applications as a new class of high-temperature structural materials.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang: Adv. Eng. Mater., 2004, vol. 6, pp. 299-303.

Y. Dong, K.Y. Zhou, Y.P. Lu, X.X. Gao, T.M. Wang, and T.J. Li: Mater. Des., 2014, vol. 57, pp. 67-72.

L. Jiang, Z.Q. Cao, J.C. Jie, J.J. Zhang, Y.P. Lu, T.M. Wang, and T.J. Li: J. Alloy. Compd., 2015, vol. 649, pp. 585-590.

C. Li, Y.F. Xue, M.T. Hua, T.Q. Cao, L.L. Ma, and L. Wang: Mater. Des., 2016, vol. 90, pp. 601-609.

D.C. Ma, M.J. Yao, K.G. Pradeep, C.C. Tasan, H. Springer, and D. Raabe: Acta. Mater., 2015, vol. 98, pp. 288-296.

M.R. Chen, S.J. Lin, J.W. Yeh, S. Chen, Y.S. Huang, and M.H. Chuang: Metall. Mater. Trans., 2006, vol. 37, pp. 1363-1369.

M.H. Chuang, M.H. Tsai, W.R. Wang, S.J. Lin, and J.W. Yeh: Acta. Mater., 2011, vol. 59, pp. 6308-6317.

Z.T. Zhang, Eugen Axinte, W.J. Ge, C.Y. Shang, and Y. Wang: Mater. Des., 2016, vol. 108, pp. 106-113.

O.N. Senkov and C.F. Woodward: Mater. Sci. Eng. A., 2011, vol. 529, pp. 311-320.

A. Poulia, E. Georgatis, A. Lekatou, and A.E. Karantzalis: Int. J. Refract. Met. Hard. Mater., 2016, vol. 57, pp. 50-63.

Mitsuharu Todai, Takeshi Nagase, Takao Hori, Aira Matsugaki, Aiko Sekita, and Takayoshi Nakano: Scripta. Mater., 2017, vol. 129, pp. 65-68.

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle: Intermetallics., 2011, vol. 19, pp. 698-706.

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw: Intermetallics., 2010, vol. 18, pp. 1758-1765.

O. N. Senkov, J. M. Scott, S. V. Senkova, F. Meisenkothen, D. B. Miracle, and C. F. Woodward: J. Mater. Sci., 2012, vol. 47, pp. 4062-4074.

C.C. Juan, K.K. Tseng, W.L. Hsu, M.H. Tsai, C.W. Tsai, C.M. Lin, S.K. Chen, S.J. Lin, and J.W. Yeh: Mater. Lett., 2016, vol. 175, pp. 284-287.

Z.D. Han, N. Chen, S.F. Zhao, L.W. Fan, G.N. Yang, Y. Shao, and K.F. Yao: Intermetallics., 2017, vol. 84, pp. 153-157.

Y.D. Wu, Y.H. Cai, X.H. Chen, T. Wang, J.J. Si, L. Wang, Y.D. Wang, and X.D. Hui: Mater. Des., 2015, vol. 83, pp. 651-660.

H. Chen, A. Kauffmann, B. Gorr, D. Schliephake, C. Seemüller, J.N. Wagner, H.-J. Christ, and M. Heilmaier: J. Alloy. Compd., 2016, vol. 661, pp. 206-215.

A.E. Karantzalis, A. Poulia, E. Georgatis, and D. Petroglou: Scripta. Mater., 2017, vol. 131, pp. 51-54.

N.D. Stepanov, N.Yu. Yurchenko, E.S. Panina, M.A. Tikhonovsky. and S.V. Zherebtsov: Mater. Lett., 2017, vol. 188, pp. 162-164.

O.N. Senkov, S.V. Senkova, D.B. Miracle, and C. Woodward: Mater. Sci. Eng. A., 2013, vol. 565, pp. 51-62.

O.N. Senkov, S.V. Senkova, C. Woodward, and D.B. Miracle: Acta. Mater., 2013, vol. 61, pp. 1545-1557.

N.Yu. Yurchenko, N.D. Stepanov, D.G. Shaysultanov, M.A. Tikhonovsky, and G.A. Salishchev: Mater. Charact., 2016, vol. 121, pp. 125-134.

N.D. Stepanov, N. Yu Yurchenko, D.V. Skibin, M.A. Tikhonovsky, and G.A. Salishchev: J. Alloy. Compd., 2015, vol. 652, pp. 266-280.

M.N. Zhang, X.L. Zhou, and J.H. Li: J. Mater. Eng. Perform., 2017, vol. 26, pp. 3657-3665.

H. Zhang, Y. Pan, and Y.Z. He: Acta. Metall. Sin., 2011, vol. 47, pp. 1075-1079.

X Yang, Y Zhang (2012) Mater. Chem. Phys. 132:233-238.

S. Guo, and C. T. Liu: Prog. Nat. Sci-Mater., 2011, vol. 21, pp. 433-436.

Akira Takeuchi, and Akihisa Inoue: Mater. Trans., 2005, vol. 46, pp. 2817-2829.

J.H. Pi, Y. Pan, L. Zhang, and H. Zhang: J. Alloy. Compd., 2011, vol. 509, pp. 5641-5645.

Z.J. Wang and S. Guo, C.T. Liu: JOM., 2014, vol. 66, pp. 1966-1972.

Y. Dong, Y.P. Lu, L. Jiang, T.M. Wang, and T.J. Li: Intermetallics., 2014, vol. 52, pp. 105-109.

N. Yurchenko, N. Stepanov, and G. Salishchev: Maters. Sci. Tech-lond., 2017, vol. 33, pp. 17-22.

F. He, Z.J. Wang, P. Cheng, Q. Wang, J.J. Li, Y.Y. Dang, J.C. Wang, and C.T. Liu: J. Alloy. Compd., 2016, vol. 656, pp. 284-289.

W.H. Liu, J.Y. He, H.L. Huang, and H. Wang, Z.P. Lu, C.T. Liu: Intermetallics., 2015, vol. 60, pp. 1-8.

L. Jiang, Y.P. Lu, W. Wu, Z.Q. Cao, and T.J. Li: J. Mater. Sci. Technol., 2016, vol. 32, pp. 245-250.

M.N. Zhang, X.L. Zhou, X.N. Yu, and J.H. Li: Surf. Coat. Tech., 2017, vol. 311, pp. 321-329.

T.T. Shun, L.Y. Chang, and M.H. Shiu: Mater. Sci. Eng. A., 2012, vol. 556, pp. 170-174.

Y. Dong, Y.P. Lu, J.R. Kong, J.J. Zhang, and T.J. Li: J. Alloy. Compd., 2013, vol. 573, pp. 96-101.

N.N. Guo, L. Wang n, L.S. Luo, X.Z. Li, R.R. Chen, Y.Q. Su n, J.J. Guo, and H.Z. Fu: Mater. Sci. Eng. A., 2016, vol. 651, pp. 698-707.

Y. Liu, Y. Zhang, H. Zhang, N.J. Wang, X. Chen, H.W. Zhang, and Y.X. Li: J. Alloy. Compd., 2017, vol. 694, pp. 869-876.

C.C. Juan, M.H. Tsai, C.W. Tsai, C.M. Lin, W.R. Wang, C.C. Yang, S.K. Chen, S.J. Lin, and J.W. Yeh: Intermetallics., 2015, vol. 62, pp. 76-83.

D.B. Miracle, and O.N. Senkov: Acta. Mater., 2017, vol. 122, pp. 448-511.

Acknowledgments

This research was supported by the National Key Research and Development Program of China (Grant No. 2017YFB0306102), the National Natural Science Foundation of China (Grant No. 51271034) and the Fundamental Research Funds for the Central Universities (Grant No. FRF-BR-16-023A).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 25, 2017.

Rights and permissions

About this article

Cite this article

Zhang, M., Zhou, X., Zhu, W. et al. Influence of Annealing on Microstructure and Mechanical Properties of Refractory CoCrMoNbTi0.4 High-Entropy Alloy. Metall Mater Trans A 49, 1313–1327 (2018). https://doi.org/10.1007/s11661-018-4472-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4472-z