Abstract

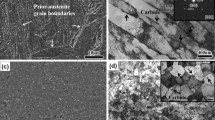

Ultrafine-grained (UFG) dual-phase (DP) steel was produced by severe cold rolling (true strain of 2.4) and intercritical annealing of a low carbon V-Nb microalloyed steel in a temperature range of 1003 K to 1033 K (730 °C to 760 °C) for 2 minutes, and water quenching. The microstructure of UFG DP steels consisted of polygonal ferrite matrix with homogeneously distributed martensite islands (both of size <1 µm) and a small fraction of the inter lath films of retained austenite. The UFG DP steel produced through intercritical annealing at 1013 K (740 °C) has good combination of strength (1295 MPa) and ductility (uniform elongation, 13 pct). The nanoscale V- and Nb-based carbides/carbonitrides and spheroidized cementite particles have played a crucial role in achieving UFG DP microstructure and in improving the strength and work hardening. Analysis of work hardening behavior of the UFG DP steels through modified Crussard–Jaoul analysis showed a continuously varying work hardening rate response which could be approximated by 2 or 3 linear regimes. The transmission electron microscopy analysis on post tensile-tested samples indicated that these regimes are possibly related to the work hardening of ferrite, lath, and twin martensite, respectively.

Similar content being viewed by others

References

ULSAB-AVC Body Structure Materials, Technical Transfer Dispatch No. 6, May, 2001.

Y. T Zhu, and C. L. Terry, Mater. Sci. Eng. A, 2000, vol. 291, pp. 46–53

Z. Horita, T. Fujinami, and T. G. Langdon, Mater. Sci. Eng. A, 2001, vol.318, pp. 34-41.

G. Frommeyer, and J. A. Jiménez, Metall. Mater. Trans. A, 2005, vol. 36A, pp. 295–300.

H. Conrad, and J. Narayan Acta Mater., 2002, vol. 50, pp. 5067–78.

H. Conrad, Mater. Sci. Eng. A, 2003, vol.341, pp. 216–28.

N. Tsuji, Y. Ito, Y. Saito, and Y. Minamino, Scripta Mater., 2002, vol. 47, pp. 893–99.

D. Jia, K.T. Ramesh, and E. Ma, Acta Mater., 2003, vol. 3, pp. 3495–509.

M. Calcagnotto, D. Ponge, and D. Raabe, Mater. Sci. Eng. A, 2010, vol. 527, pp. 2738–46.

M. Papa Rao, V. Subramanya Sarma and S. Sankaran, Metall. Mater. Trans. A, 2014, vol. 45A, pp. 5313–17.

KT. Park, YK. Lee, and DH. Shin, ISIJ Int., 2005, vol. 45, pp. 750–55.

Y.I. Son, Y.K. Lee, K.T. Park, C.S. Lee, and D.H. Shin, Acta Mater., 2005, vol. 53, pp. 3125–34.

M. Okayasu, K. Sato, M. Mizuno, DY. Hwang, and D.H. Shin, Int. J. Fatigue, 2008, vol. 30, pp. 1358–65.

M. Delince, Y. Brechet, J.D. Embury, M.G.D. Geers, P.J. Jacques, and T. Pardoen, Acta Mater., 2007, vol.55,pp. 2337–50.

M. Calcagnotto, D. Ponge, and D. Raabe Mater. Sci. Eng. A, 2010, vol.527, pp. 7832–40.

K.T. Park, S.Y. Han, B.D. Ahn, D.H. Shin, Y.K. Lee and K.K. Um, Scripta Mater., 2004, vol.51,pp. 909–13.

M. Papa Rao, V. Subramanya Sarma and S. Sankaran, Mater. Sci. Eng. A, 2013, vol. 568, pp. 171–175.

H. Aziz-Alizamini, and M. Militzer, WJ. Poole, Scr. Mater., 2007, vol.57, pp. 1065–68.

M.D. Abramoff, P.J. Magelhaes, and S.J. Ram, Biophotonics Int., 2004, vol. 11, pp. 36–42.

Y. Ivanisenko, X.I. Sauvage, MacLaren and H.J. Fecht, Nano Sci. Technol., 2009, vol. 2, pp. 41–55.

G.R. Speich, V.A. Demarest, and R.L. Miller Metall. Trans. A, 1981, vol. 12A, pp. 1419–28

M. Hillert, K. Nilsson, and L.E. Torndahl, J. Iron Steel Inst., 1971, vol.209, pp. 49–66.

N. Peranio, Y.J. Li, F. Roters, D. Raabe, Mater. Sci. Eng. A, 2010, vol. 527 pp. 4161–4168.

J.Gautam, A. Miroux, J. Moerman, C. Barbatti, L.A.I. Kestens Mater. Sci. Forum 2011, vols. 702–703, pp. 778–81.

R.K. Ray, J. Mater. Sci. Lett., 1985, vol. 4, pp. 67–70.

D.K. Mondal and R.K. Ray, Mater. Sci. Eng. A, 1992, vol.158, pp. 147-56.

R.A. Knot and J.W. Morris, AIME, 1979, pp. 1–19.

M. Erdogan, Scripta Mat., 2003, vol.48, pp. 501–06.

M. Erdogan, J. Mat. Sci., 2002, vol.37, pp. 3623–30.

M. Erdogan, R. Priestner, Mat. Sci. Tech., 1999, vol.15, pp. 1273–84.

R.G. Davies, Metall. Trans. A, 1978, vol. 9A, pp. 671–79.

R.G. Davies, Metall. Trans. A, 1979, vol. 10, pp. 1549–55.

R.W.K. Honeycombe and H.K.D.H. Bhadeshia, Steels Microstructure and Properties, 2nd Edition. Edward Arnold: London, 1995.

G. Garmong and R.B. Thompson, Metall. Trans., 1973, vol. 4, pp. 863–73.

A.R. Marder, Metall. Trans. A, 1981, vol. 12, pp. 1569–79.

Z. Fan and A.P. Miodownik, Scr. Metall., 1993, vol. 28, pp. 895–900

A. Bag, K.K. Ray, E.S. Dwarakadasa, Metall. Mater. Trans. A, 1999, vol. 30A, pp. 1193–202.

T. Hayashi, K. Nagai, T. Hanamura, Camp-ISIJ Int., 2000, vol. 13, pp. 473–76.

M. Mazinani, W.J. Poole, Metall. Mater. Trans. A, 2007, vol. 38A, p. 328.

H. Saghafian, S.H. Kheirandish, Mater. Lett., 2007, vol. 61, pp. 3059–63.

R. K. Ray, J. J. Jonas & R. E. Hook Int. Mater. Rev., 1994, vol. 39, pp. 139–72

R.E. Reed-Hill, W.R Cribb, and S.N Monteiro Metall. Mater. Trans. B, 1973, vol. 4B, pp. 2665–67.

H.W. Swift and J. Mech. Phys. Solids, 1 1952, vol. 1, pp. 1–18.

Y. Tomita, K. Okabayashi. Metall. Trans. A, 1985, vol. 65, pp 865–72.

V. Colla, M. De Sanctis, A. Dimatteo, G. Lovicu, A. Solina and R. Valentini, Metall. Mater. Trans. A, 2009, vol. 40A, pp 2557–67

I. Timokhina, E. Pereloma and P. Hodgson, Metall. Mater. Trans. A, 2014, vol. 45A, pp 4247–55.

A. Karmakar, S. Sivaprasad, S. Kundu and D. Chakrabarti, Metall. Mater. Trans. A, 2014, vol. 45 A, pp 1659–63.

Acknowledgments

The authors acknowledge the financial support of DST, Govt. of India through a sponsored project for the above research work. They are also thankful to Dr. Arnab Chattopadhyay formerly with TATA Steel, Jamshedpur, India for gifting the V-Nb microalloyed steels for the research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted November 1, 2015.

Rights and permissions

About this article

Cite this article

Papa Rao, M., Subramanya Sarma, V. & Sankaran, S. Microstructure and Mechanical Properties of V-Nb Microalloyed Ultrafine-Grained Dual-Phase Steels Processed Through Severe Cold Rolling and Intercritical Annealing. Metall Mater Trans A 48, 1176–1188 (2017). https://doi.org/10.1007/s11661-016-3889-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3889-5