Abstract

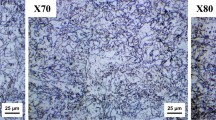

The correlation between the microstructures and tensile properties of strain-based American Petroleum Institute (API) X60 pipeline steels was investigated. Eight types of strain-based API X60 pipeline steels were fabricated by varying the chemical compositions, such as C, Ni, Cr, and Mo, and the finish cooling temperatures, such as single-phase and dual-phase regions. In the 4N and 5C steels, the volume fractions of bainitic ferrite (BF) and the secondary phases increased with the increasing C and adding Cr instead of Ni. In the 5C and 6NC steels, the volume fractions of acicular ferrite (AF) and BF decreased with increasing C and adding Ni, whereas the volume fractions of polygonal ferrite (PF) and the secondary phases increased. In the 6NC and 6NM steels, the volume fraction of BF was increased by adding Mo instead of Cr, whereas the volume fractions of PF and the secondary phases decreased. In the steels rolled in the single-phase region, the volume fraction of polygonal ferrite ranged from 40 to 60 pct and the volume fraction of AF ranged from 20 to 40 pct. In the steels rolled in the dual-phase region, however, the volume fraction of PF was more than 70 pct and the volume fraction of AF was below 20 pct. The strength of the steels with a high volume fraction of AF was higher than those of the steels with a high volume fraction of PF, whereas the yield point elongation and the strain hardening exponent were opposite. The uniform elongation after the thermal aging process decreased with increasing volume fraction of PF, whereas the uniform elongation increased with increasing volume fraction of AF. The strain hardening exponent increased with increasing volume fraction of PF, but decreased with increasing volume fraction of AF and effective grain size.

Similar content being viewed by others

References

R. Denys: Pipeline Technology Conference, Elsevier, Amsterdam, 2000, vol. I & II, pp. 1-166.

J.Y. Koo, M.J. Luton, N.V. Bangaru, R.A. Petkovic, D.P. Fairchild, C.W. Petersen, H. Asahi, T. Hara, Y. Terada, M. Sugiyama, H. Tamehiro, Y. Komizo, S. Okaguchi, M. Hamada, A. Yamamoto, and I. Takeuchi: Proc. 13th Int. Offshore Polar Eng. Conf., Honolulu, Hawaii, 2003, pp. 10–18.

X.-L. Yang, Y.-B. Xu, X.-D. Tan, and D. Wu: Mater. Sci. Eng. A, 2014, vol. 607, pp. 53-62.

Y. Shinohara, T. Hara, E. Tsuru, H. Asahi, Y. Terada, and N. Doi: Int. Conf. Offshore Mech. Arctic Eng., OMAE, Halkidiki, Greece, 2005, pp. 27–84.

D.B. Lillig: Proc. 18th Int. Offshore Polar Eng. Conf., Vancouver, Canada, 2008, pp. 1–12.

K. Nagai, Y. Shinohara, S. Sakamoto, E. Tsuru, and H. Asahi: Proc. 19th Int. Offshore Polar Eng. Conf., Osaka, Japan, 2009, pp. 56–60.

G. Shigesato, Y. Shinohara, T. Hara, M. Sugiyama, and H. Asahi: Proc. 16th Int. Offshore Polar Eng. Conf., Lisbon, Portugal, 2007, pp. 2983–87.

T. Hara, Y. Shinohara, Y. Terada, H. Asahi, and N. Doi: Proc. 19th Int. Offshore Polar Eng. Conf., Osaka, Japan, 2009, pp. 73–79.

Y. Shinohara, T. Hara, E. Tsuru, and H. Asahi: Proc. 16th Int. Offshore Polar Eng. Conf., Lisbon, Portugal, 2007, pp. 2949–2954.

J.H. Baek, Y.P. Kim, C.M. Kim, W.S. Kim, and C.S. Seok: Mater. Sci. Eng. A, 2010, vol. 527, pp. 1473-79.

T. Hara, Y. Shinohara, Y. Hattori, T. Muraki, and N. Doi: Proc. 21th Int. Offshore Polar Eng. Conf., ISOPE, Hawaii, USA, 2011, pp. 575–80.

I. Tamura, H. Sekine, T. Tanaka, and C. Ouchi: Thermomechanical Processing of High-Strength Low-Alloy Steels, Butterworth-Heinemann, Oxford, 1988, pp. 80-100.

T. Sourmail and V. Smanio: Acta Mater., 2013, vol. 61, pp. 2639-48.

J. Speer, D.K. Matlock, B.C. De Cooman, and J.G. Schroth: Acta Mater., 2013, vol. 51, pp. 2611-22.

M.I. Isik, A. Kostka, V.A. Yardley, K.G. Pradeep, M.J. Duarte, P.P. Choi, D. Raabe, and G. Eggeler: Acta Mater., 2015, vol. 90, pp. 94-104.

Z.H. Tang and W. Stumpf: Mater. Charact., 2008, vol. 59, pp. 717-28.

V. Randle and O. Engler: Introduction to Texture Analysis, CRC Press, Boca Raton, FL, 2014, pp. 153–88.

ASTM Standard E8/E8m-13a: Standard Test Methods for Tension Testing of Metallic Materials, ASTM, West Conshohocken, PA, 2013.

S.W. Thompson, D.J. Colvin, and G. Krauss: Metall. Mater. Trans. A, 1990, vol. 21A, pp. 1493-1507.

20. T. Araki: Atlas for Bainitic Microstructures, ISIJ, Tokyo, 1992, pp. 1–100.

G. Krauss and S.W. Thompson: ISIJ Int., 1995, vol. 35, pp. 937-45.

H.K.D.H. Bhadeshia: Mater. Sci. Eng. A, 2004, vol. A378, pp. 34-39.

H. Ohtani, S. Okaguchi, Y. Fujishiro, and Y. Ohmori: Metall. Trans. A, 1990, vol. 21, pp. 877-88.

M. Diaz-Fuentes, A. Iza-Mendia, and I. Gutierrez: Metall. Mater. Trans. A, 2003, vol. 34A, pp. 2505-16.

B.L. Bramfitt and J.G. Speer: Metall. Trans. A, 1990, vol. 21, pp. 817-29.

F.G. Caballero, M.K. Miller, C. Garcia-Mateo, J. Cornide, and M.J. Santofimia: Scripta Mater., 2012, vol. 27, pp. 846-49.

W.B. Lee, S.G. Hong, C.G. Park, K.H. Kim, and S.H. Park: Scripta Mater., 2000, vol. 43, pp. 319-24.

H. Asahi: ISIJ Int., 2002, vol. 42, pp. 1150-55.

M. Calcagnotto, Y. Adachi, D. Ponge, and D. Raabe: Acta Mater., 2011, vol. 59, pp. 658-70.

D. Hull and D.J. Bacon: Introduction to Dislocations, 5th Ed., Elsevier Ltd., Amsterdam, 2011, pp. 1-272.

31. A.H. Cottrell: Trans. Am. Inst. Mech. Eng.. 1958, vol. 212, pp. 192-203.

A. Ma, F. Roters, and D. Raabe: Acta Mater., 2006, vol. 54, pp. 2181-94.

N.J. Kim and G. Thomas: Scripta Metall., 1984, vol. 18, pp. 817-20.

R.T. Li, X.R. Zuo, Y.Y. Hu, Z.W. Wang, and D.X. Hu: Mater. Charact., 2011, vol. 62, pp. 801-06.

L.P. Kubin and A. Mortensen: Scripta Mater., 2003, vol. 48, pp. 119-25.

H. Gao, Y. Huang, W.D. Nix, and J.W. Hutchinson: J. Mech. Phys. Solids, 1999, vol. 47, pp. 1239-63.

M. Calcagnotto, D. Ponge, E. Demir, and D. Raabe: Mater. Sci. Eng. A, 2010, vol. 527, pp. 2738-46.

Acknowledgments

This work was supported by the Ministry of Knowledge Economy under a Grant No. 100400-25, the Ministry of Land, the Infrastructure and Transport under a Grant No. 14IFIP-B067087-02-000000 and the 2013 Research Fund of University of Ulsan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 16, 2015.

Rights and permissions

About this article

Cite this article

Sung, H.K., Lee, D.H., Lee, S. et al. Correlation Between Microstructures and Tensile Properties of Strain-Based API X60 Pipeline Steels. Metall Mater Trans A 47, 2726–2738 (2016). https://doi.org/10.1007/s11661-016-3453-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3453-3