Abstract

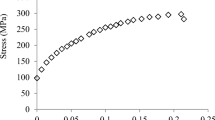

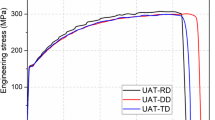

Hot tensile tests were conducted using a Gleeble 1500, at the temperature range of 623 K to 823 K (350 °C to 550 °C) and strain rate range of 0.1 to 10 s−1. Flow stress is significantly affected by temperature and strain rate. As strain increases; the flow stress first rapidly increases, subsequently maintains a steady state, and finally drops sharply because of damage evolution. The features and mechanism of the damage were studied utilizing a scanning electron microscope. Micro-void nucleation, growth, and coalescence result in the failure of the hot-formed specimen. A damage equation based on continuum damage mechanics and damage mechanism in hot metal forming was proposed. A unified viscoplastic damage model coupled with strain, strain rate, temperature, dislocation, hardening, damage, damage rate, and so on was developed and calibrated for AA6111 using Genetic Algorism Tool in three steps. This model can be used to describe viscoplastic flow behavior and damage evolution at various temperatures and strain rates. The model was implemented into the finite element (FE) model in ABAQUS platform via the variable user material subroutine. Thus, the FE model could be employed to study the damage distribution and the effects of blank holder force (BHF) and forming velocity on hot cylindrical deep drawing. It is revealed that lower BHF and higher velocity are beneficial for drawability. A good agreement between simulated and experimental results has been achieved.

Similar content being viewed by others

References

A. Tewari, S. Vijayalakshmi, S. Tiwari, P. Biswas, S. Kim, R.K. Mishra, R. Kubic, and A.K. Sachdev: Metall. Mater. Trans. A, 2013, vol. 44, pp. 2382-2398.

C.D. Marioara, S.J. Andersen, J. Røyset, O. Reiso, S. Gulbrandsen-Dahl, T. Nicolaisen, I. Opheim, J.F. Helgaker, and R. Holmestad: Metall. Mater. Trans. A, 2014, vol. 45, pp. 2938-2949.

N. Anjabin, A.K. Taheri, and H.S. Kim: Metall. Mater. Trans. A, 2013, vol. 44, pp. 5853-5860.

Y. Tu, H. Qian, X. Zhou, and J. Jiang: Metall. Mater. Trans. A, 2014, vol. 45, pp. 1883-1891.

J. Zhou, B. Wang, J. Lin, and L. Fu: Arch. Civ. Mech. Eng, 2013, vol. 13, pp. 401-411.

C. Poletti, T. Wójcik, and C. Sommitsch: Metall. Mater. Trans. A, 2013, vol. 44, pp. 1577-1586.

L. Shi, H. Yang, L.G. Guo, and J. Zhang: Mater. Design, 2014, vol. 54, pp. 576-581.

L. Li, Y.C. Lin, H. Zhou, and Y. Jiang: Comp. Mater. Sci., 2013, vol. 73, pp. 72-78.

M.J. Roy, D.M. Maijer, and L. Dancoine: Mater. Sci. Eng. A, 2012, vol. 548, pp. 195-205.

J. Li, F. Li, J. Cai, R. Wang, Z. Yuan, and G. Ji: Comp. Mater. Sci., 2013, vol. 71, pp. 56-65.

J. Lin, B.H. Cheong, and X. Yao: J. Mater. Process. Tech., 2002, vol. 125–126, pp. 199-205.

Y. Estrin: J. Mater. Process. Tech., 1998, vol. 80–81, pp. 33-39.

Ø. Grong and H.R. Shercliff: Prog. Mater. Sci., 2002, vol. 47, pp. 163-282.

M. Zhou and F. P. E. Dunne: J. Strain Anal. Eng. Des., 1996, vol. 31, pp. 187-196.

J. Lin and J. Yang: Int. J. Plasticity, 1999, vol. 15, pp. 1181-1196.

H.R. RezaeiAshtiani, M.H. Parsa, and H. Bisadi: Mater. Sci. Eng. A, 2012, vol. 545, pp. 61–67.

D. Lassance, D. Fabregue, F. Delannay, and T. Pardoen: Prog. Mater. Sci., 2007, vol. 52, pp. 62-129.

M.S. Mohamed, A.D. Foster, J. Lin, D.S. Balint, and T.A. Dean: Int. J. Mach. Tools Manuf., 2012, vol. 53, pp. 27-38.

J. Lin: Int. J. Damage Mech., 2005, vol. 14, pp. 299-319.

S. Thuillier, N. Le Maout, and P.Y. Manach: Mater. Design, 2011, vol. 32, pp. 2049-2057.

Y.F. Lung, M.C. Lin, H.C. Lin, and K.M. Lin: Mater. Design, 2011, vol. 32, pp. 4369-4375.

M.A. Khaleel, H.M. Zbib, and E.A. Nyberg: Int. J. Plasticity, 2001, vol. 17, pp. 277-296.

Y. Liu and J. Lin: J. Mater. Process. Technol., 2003, vol. 143–144, pp. 723–28.

R.P. Garrett, J. Lin, and T.A. Dean: Int. J. Plasticity, 2005, vol. 21, pp. 1640-1657.

J. Lin and T.A. Dean: J. Mater. Process. Tech., 2005, vol. 167, pp. 354-362.

H. Agarwal, A.M. Gokhale, S. Graham, and M.F. Horstemeyer: Mater. Sci. Eng. A, 2003, vol. 341, pp. 35-42.

Acknowledgments

The authors would like to acknowledge the financial support provided by the State Key Laboratory of Materials Processing and Die & Mould Technology, Huazhong University of Science and Technology (No. P2014-15), the Specialized Research Fund for the Doctoral Program of Higher Education of China (No. 20120006110017) and Beijing Laboratory of Metallic Materials and Processing for Modern Transportation. The authors are also grateful to Professor Jianguo Lin, Royal Academy of Engineering and Department of Mechanical Engineering, Imperial College, UK for the guidance and help.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 3, 2015.

Rights and permissions

About this article

Cite this article

Ma, W., Wang, B., Bian, J. et al. A New Damage Constitutive Model for Thermal Deformation of AA6111 Sheet. Metall Mater Trans A 46, 2748–2757 (2015). https://doi.org/10.1007/s11661-015-2823-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2823-6