Abstract

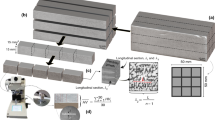

The solidification kinetics of a high strength B206 aluminum casting alloy as a function of cooling rates between 1 and 15 K/min has been characterized through a combination of differential scanning calorimetry (DSC), scanning electron microscopy (SEM), and optical microscopy. Three different peaks were detected in the DSC analysis, which corresponded to the nucleation of an α-Al solid solution, an Al-Cu-Fe intermetallic, and the eutectic phases. The presence of these phases was confirmed using a coupled SEM–energy dispersive spectroscopy analysis. The α-Al nucleation temperature was found to be independent of cooling rate while the eutectic and the intermetallic formation temperatures were depressed by up to 20 K (20 °C). The evolution of the fraction solid, particularly during the solidification of α-Al was also affected by the cooling rate in such a way that slower cooling was accompanied by a higher fraction solid at a given temperature. Concurrently, microscopy was used in order to quantify the variation in secondary dendrite arm spacing with cooling rate for use in numerical simulations of casting processes.

Similar content being viewed by others

Notes

The B206 alloy has reduced levels Ti and Fe as compared to the traditional 206-type variant so that grain refinement via TiB2 will be effective.

References

D. Carle, B. Gordon, Mater. Des. 20 (1999) 267.

S. Das, W. Yin, JOM 59 (2007) 83.

L. Backerud, C. Guocai, T. Jarmo, AFS 2 (1990) 266.

J.F. Major, G.K. Sigworth, Trans. AFS 114 (2006) 117.

F. D’Elia, C. Ravindran, D. Sediako, Can. Metal. Quart. 53 (2014) 151.

M. Manivannan, D.O. Northwood, and J.H. Sokolowski: 3rd International Conference on Integrity, Reliability and Failure, Porto/Portugal, 2009.

F. D’Elia, C. Ravindran, Trans. Indian Inst. Metals 62 (2009) 315.

H. Kamali, M. Emamy, A. Razaghian, Mater. Sci. Eng. A 590 (2014) 161.

H.K. Kamga, D. Larouche, M. Bournane, A. Rahem, Metal. Mater. Trans. A 41 (2010) 2844.

K. Liu, X. Cao, X.G. Chen, Metal. Mater. Trans. A 42 (2011) 2004.

E.M. Elgallad, X.G. Chen, Mater. Sci. Eng. A 556 (2012) 783.

D.G. Eskin, Q. Du, D. Ruvalcaba, L. Katgerman, Mater. Sci. Eng. A 405 (2005) 1.

M.A. Talamantes-Silva, A. Rodríguez, J. Talamantes-Silva, S. Valtierra, R. Colás, Metal. Mater. Trans. B 39 (2008) 911.

K. Liu, X. Cao, X.G. Chen, J. Mater. Sci. 47 (2012) 4290.

H. Iwasaki, T. Mori, M. Mabuchi, K. Higashi, Acta Mater. 46 (1998) 6351.

H.B. Dong, M.R.M. Shin, E.C. Kurum, H. Cama, J.D. Hunt, Fluid Phase Equilibr. 212 (2003) 199.

H.B. Dong, R. Brooks, Mater. Sci. Eng. A 413 (2005) 480.

N. D’Souza, M. Lekstrom, H.J. Dai, B.A. Shollock, H. B. Dong, Mater. Sci. Technol. 23 (2007) 1085.

N. D’Souza, H.B. Dong, Scripta Mater. 56 (2007) 41.

N. D’Souza, H. B. Dong, Mater. Sci. Technol. 27 (2011) 325.

U.R. Kattner, K.W. Moon, and J.H. Perepezko: US Department of Commerce, Technology Administration, National Institute of Standards and Technology, 2006.

L. Backerud, Solidification characteristics of aluminum alloys. American foundrymen’s Society, Des Plains, IL, 1986.

M.A. Talamantes-Silva, A. Rodriguez, J. Talamantes-Silva, S. Valtierra, R. Colás, Mater. Charac. 59 (2008) 1434.

K. Liu, X. Cao, X.G. Chen, Metal. Mater. Trans. B 43 (2012) 1231.

Q.G. Wang, C. J. Davidson, J. Mater. Sci. 36 (2001) 739.

D. Larouche, C. Laroche, M. Bouchard, Acta Mater. 51 (2003) 2161.

S. Thompson, S.L. Cockcroft, M.A. Wells, Mater. Sci. Technol. 20 (2004) 194.

H.K. Kamga, D. Larouche, M. Bournane, A. Rahem, Mater. Sci. Eng. A 527 (2010) 7413.

J.A. Sarreal, G.J. Abbaschian, Metal. Trans. A 17 (1986) 2063.

S. Nafisi, D. Emadi, R. Ghomashchi, Mater. Sci. Eng. A 507 (2009) 87.

M.C. Flemings, Solidification Processing, McGraw-Hill, NY, USA, 1974.

J.A. Horwath, L.F. Mondolfo, Acta Metal. 10 (1962) 1037.

A.B. Michael, M.B. Bever. Trans. Metall. Soc. AIME (1954) 200:47.

M. Solari, H. Biloni, J. Cryst. Growth 49 (1980) 451.

J.B. Wiskel, K. Navel, H. Henein, E. Maire, Can. Metal. Quart. 41 (2002) 193.

S.G. Shabestari, M. Malekan, Can. Metal. Quart. 44 (2005) 305.

M. Easton, J.F. Grandfield, D.H. StJohn, B. Rinderer, Mater. Sci. Forum 519 (2006) 1675.

Acknowledgments

The authors would like to thank the Natural Sciences and Engineering Research Council of Canada (NSERC) and partner companies within the Strategic Project “Through-Process Modelling: Castings for Marine Energy Systems” for funding this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 30, 2014.

Rights and permissions

About this article

Cite this article

Haghdadi, N., Phillion, A.B. & Maijer, D.M. Microstructure Characterization and Thermal Analysis of Aluminum Alloy B206 During Solidification. Metall Mater Trans A 46, 2073–2081 (2015). https://doi.org/10.1007/s11661-015-2780-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-015-2780-0