Abstract

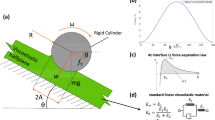

Friction stir welding generates periodic features within the weld. These “onion ring” features are associated with variations in both texture and the orientation of that texture along the length of the weld. Analysis of an AA2195 friction stir weld reveals the presence of periodic oscillations between the dominant B and \( \overline{\text{B}} \) components of the ideal shear texture, suggesting a periodic reversal in the predominant shear orientation during welding that is inconsistent with current understandings of the friction stir welding process. Microstructural features present in the weld and machine force variations during welding indicate that these textures may arise from the oscillation of an off-centered tool. Such a tool oscillation can generate a periodic extrusion of material around the tool, giving rise to the observed flow features, machine force variations, and reversals of the local shear texture orientations. A new model of material flow during friction stir welding is proposed to explain the observed features.

Similar content being viewed by others

References

W.M. Thomas, E.D. Nicholas, J.C. Needham, M.G. Murch, P. Templesmith, and C.J. Dawes: International Patent Application No. PCT/GB92/02203 and GB Patent Application No. 9125978.8, Dec. 1991, U.S. Patent No. 5,460,317, Oct. 1995.

A.C. Nunes, Jr.: Aluminum 2001: TMS 2001 Annual Meeting Aluminum Automotive and Joining Symposia, S.K. Das, J.G. Kaufmann, and T.J. Leinert, eds., TMS, Warrendale, PA, 2001, pp. 235–48.

J.A. Schneider and A. C. Nunes, Jr.: Metall. Mater. Trans. B, 2004, vol. 35B, pp. 777–83.

R.W. Fonda and K.E. Knipling: Sci. Technol. Weld. Join., 2011, vol. 16, pp. 288–94.

C.J. Dawes and W.M. Thomas: Weld. J., 1996, vol. 75(3), pp. 41–45.

H. Larsson, L. Karlsson, and L.-E. Svensson: Proceedings of the 6th International Conference on Aluminum Alloys, ICAA-6, Toyohashi, Japan, 1998, pp. 1471–76.

J. Karlsson, B. Karlsson, H. Larsson, L. Karlsson, and L.-E. Svensson: INALCO ‘98: 7th International Conference on Joints in Aluminium, TWI, Cambridge, U.K., 1998, pp. 231–40.

P.L. Threadgill: TWI Members Report 678/1999, TWI, Cambridge, U.K., 1999.

A.J. Leonard: TWI Members Report 683/1999, TWI, Cambridge, U.K., 1999.

M.A. Sutton, B. Yang, A.P. Reynolds, and R. Taylor: Mater. Sci. Eng. A, 2002, vol. 323(1–2), pp. 160–66.

B.C. Yang, J.H. Yan, M.A. Sutton, and A.P. Reynolds: Mater. Sci. Eng. A, 2004, vol. 364(1–2), p. 55.

K. Colligan: Weld. J., 1999, vol. 78(7), pp. 229s–37s.

L.-E. Svensson, L. Karlsson, H. Larsson, B. Karlsson, M. Fazzini, and J. Karlsson: Sci. Technol. Weld. Join., 2000, vol. 5(5), pp. 285–96.

K.N. Krishnan: Mater. Sci. Eng. A, 2002, vol. 327(2), pp. 246–51.

R.W. Fonda, J.F. Bingert, and K.J. Colligan: Scripta Mater., 2004, vol. 51, pp. 243–48.

Y. Li, L.E. Murr, and J.C. McClure: Scripta Mater., 1999, vol. 40(9), pp. 1041–46.

Y. Li, L.E. Murr, and J.C. McClure: Mater. Sci. Eng. A, 1999, vol. 271, pp. 213–23.

M.W. Mahoney, C.G. Rhodes, J.G. Flintoff, R.A. Spurling, and W.H. Bingel: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 1955–64.

A.F. Norman, I. Brough, and P.B. Prangnell: Mater. Sci. Forum, 2000, vol. 331–333, pp. 1713–18.

G. Pouget and A.P. Reynolds: Int. J. Fatigue, 2008, vol. 30(3), pp. 463–72.

H.J.K. Lemmen, R.C. Alderliesten, and R. Benedictus: Int. J. Fatigue,200, vol. 33(3), pp. 466–76.

P.B. Prangnell and C.P. Heason: Acta Mater., 2005, vol. 53, pp. 3179–92.

R.W. Fonda and J.F. Bingert: Scripta Mater., 2007, vol. 57, pp. 1052–55.

M.M.Z. Ahmed, B.P. Wynne, W.M. Rainforth, and P.L. Threadgill : Scripta Mater., 2008, vol. 59, pp. 507–10.

L.S. Toth, K.W. Neale, and J.J. Jonas: Acta Metall., 1989, vol. 37(8), pp. 2197–2210.

S. Li, I.J. Beyerlein and M.A.M. Bourke: Mater. Sci. Eng. A, 2005, vol. 394(1–2), pp. 66–77.

H.J. McQueen and H. Mecking: Z. Metallkd., 1987, vol. 78(5), pp. 387–96.

Ph. Bocher, J. Azar, B.L. Adams, and J.J. Jonas: Mater. Sci. Forum, 1998, vols. 273–275, pp. 249–54.

B. Nelson and C. Sorensen: Friction Stir Welding and Processing VI, R. Mishra, M.W. Mahoney, Y. Sato, Y. Hovanski, and R. Verma, eds., TMS, Warrendale, PA, 2011, pp. 113–120.

T. Pettersen and E. Nes: Metall. Mater. Trans. A, 1998, vol. 34A, pp. 2727–36.

E.J. Gunter, Jr.: Dynamic Stability of Rotor-Bearing Systems. NASA SP-113, NASA, Washington, DC, 1966.

H.S. Samarasekera: Vibration and Shock Handbook, C.W. de Silva, ed., CRC Press, Boca Raton, FL, 2005, pp. 34–58.

E. Boldsaikhan, D.A. Burford, and P.J. Gimenez Britos: Friction Stir Welding and Processing VI, R. Mishra, M.W. Mahoney, Y. Sato, Y. Hovanski, and R. Verma, eds., TMS, Warrendale, PA, 2011, pp. 335–43.

A.P. Reynolds: Scripta Mater., 2008, vol. 58, pp. 338–42.

J.W. Qian, J.L. Li, J.T. Xiong, F.S. Zhang, W.Y. Li, and X. Lin: Sci. Technol. Weld. Join., 2012, vol. 17 (4), pp. 338–41.

Acknowledgments

RWF, CRF, KEK, and DJR would like to acknowledge funding for this research from the Naval Research Laboratory under the auspices of the Office of Naval Research and from the Structural Metallics program of ONR. APR was partially supported by the NASA-Langley Research Center and the Center for Friction Stir Processing (an NSF I/UCRC). The authors would also like to acknowledge the valuable assistance of Leroy Levenberry, Helen Fonda, and Dr. Marie Cox.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 23, 2012.

Rights and permissions

About this article

Cite this article

Fonda, R., Reynolds, A., Feng, C.R. et al. Material Flow in Friction Stir Welds. Metall Mater Trans A 44, 337–344 (2013). https://doi.org/10.1007/s11661-012-1460-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1460-6