Abstract

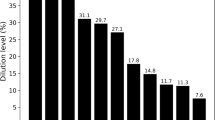

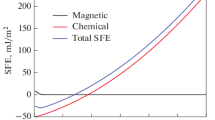

A subregular solution thermodynamic model was used to calculate the stacking fault energies (SFEs) of high-manganese (10 to 35 wt pct) steels with carbon contents of 0 to 1.2 wt pct. Based on these calculations, composition-dependent diagrams were developed showing the regions of different SFE values for the mentioned composition range. These diagrams were called SFE maps. In addition, variations in the SFE maps were observed through increasing the temperature, aluminum content, and austenite grain size. These changes were seen either as an increasing trend of SFE caused by raising the temperature and aluminum content, or as a decreasing behavior caused by increasing the grain size. The SFE value of 20 mJ/m2 within these diagrams was introduced as the upper limit for the strain-induced martensite formation. The variations in this limit caused by increasing the temperature and aluminum content were mathematically evaluated to find out the minimum amount of manganese that was required to avoid the martensitic transformation. By introducing the isocarbon and isomanganese diagrams of the SFE, it was seen that both temperature and aluminum had a greater effect on the SFE when added to the steels with the lower manganese contents. Moreover, by adding more aluminum to the composition of the high-manganese steels, its influence on the SFE decreased continuously.

Similar content being viewed by others

References

V.H. Schumann: Neue Hütte, 1972, vol. 17, pp. 605–09.

H. Schumann: J. Kristall Technik, 1974, vol. 10, pp. 1141–50.

B.W. Oh, S.J. Cho, Y.G. Kim, Y.P. Kim, W.S. Kim, and S.H. Hong: Mater. Sci. Eng., A, 1995, vol. 197, pp. 147–56.

O. Grässel, L. Krüger, G. Frommeyer, and L.W. Meyer: Int. J. Plast., 2000, vol. 16, pp. 1391–1409.

Y.K. Lee and C.S. Choi: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 355–60.

S. Allain, J.-P. Chateau, and O. Bouaziz: Mater. Sci. Eng., A, 2004, vols. 387–389, pp. 143–47.

S. Allain, J.-P. Chateau, O. Bouaziz, S. Migot, and N. Guelton: Mater. Sci. Eng., A, 2004, vols. 387–389, pp. 158–62.

A.S. Hamada: Doctoral Thesis, University of Oulu, Linnanmaa, Finland, 2007.

L. Bracke, J. Penning, and N. Akdut: Metall. Mater. Trans. A, 2007, vol. 38A, pp. 520–28.

O. Bouaziz, S. Allain, and C. Scott: Scripta Mater., 2008, vol. 58, pp. 484–87.

O. Bouaziz and N. Guelton: Mater. Sci. Eng., A, 2001, vols. 319–321, pp. 246–49.

P.J. Brofman and G.S. Ansell: Metall. Trans. A, 1978, vol. 9A, pp. 879–80.

A. Dumay, J.-P. Chateau, S. Allain, S. Migot, and O. Bouaziz: Mater. Sci. Eng., A, 2008, vols. 483–484, pp. 184–87.

W.S. Yang and C.M. Wan: J. Mater. Sci., 1990, vol. 25, pp. 1821–23.

L. Remy: Acta Metall., 1977, vol. 25, pp. 173–79.

J. Wan, S. Chen, and Z. Xu: Sci. China, 2001, vol. 44 (4), pp. 345–52.

J. Jun and C. Choi: Mater. Sci. Eng., A, 1998, vol. 257, pp. 353–56.

S. Takaki, H. Nakatsu, and Y. Tokunaga: Mater. Trans. JIM, 1993, vol. 34, pp. 489–95.

P.Y. Volosevich, V.N. Grindnev, and Y.N. Petrov: Phys. Met. Metallogr., 1976, vol. 42, pp. 126–30.

Y. Tomota, M. Strum, and J.W. Morris, Jr.: Metall. Trans. A, 1987, vol. 18A, pp. 1073–81.

K. Ishida and T. Nishizawa: Trans. JIM, 1974, vol. 15, pp. 225–31.

G. Frommeyer, U. Brüx, and P. Neumann: ISIJ Int., 2003, vol. 43 (3), pp. 438–46.

H. Ding, Z. Tang, W. Li, M. Wang, and D. Song: J. Iron Steel Res., 2006, vol. 13 (6), pp. 66–70.

K. Sato, M. Ichinose, Y. Hirotsu, and Y. Inoue: ISIJ Int., 1989, vol. 29 (10), pp. 868–77.

S. Vercammen: Doctoral Thesis, Katholieke Universiteit Leuven, Leuven, Belgium, 2004.

C. Scott, S. Allain, M. Faral, and N. Guelton: Rev. Metall., 2006, vol. 103 (6), pp. 293–302.

L. Vitos, P.A. Korzhavyi, and B. Johansson: Phys. Rev. Lett., 2006, vol. 96, paper no. 117210, pp. 1–4.

L. Vitos, J.-O. Nilsson, and B. Johansson: Acta Mater., 2006, vol. 54, pp. 3821–26.

L. Vitos and B. Johansson: in Lecture Notes in Computer Science, vol. 4699, Springer, Berlin/Heidelberg, 2007, pp. 510–19.

T. Hickel, A. Dick, B. Grabowski, F. Körmann, and J. Neugebauer: Steel Res. Int., 2009, vol. 80 (1), pp. 4–8.

C. Brandl, P.M. Derlet, and H. Van Swygenhoven: Phys. Rev. B, 2007, vol. 76, paper no. 054124, pp. 1–8.

R.E. Schramm and R.P. Reed: Metall. Trans. A, 1975, vol. 6A, pp. 1345–51.

S. Vercammen, B.C. De Cooman, N. Akdut, B. Blanpain, and P. Wollants: Steel Res., 2003, vol. 74 (6), pp. 370–75.

O. Grässel, G. Frommeyer, C. Derder, and H. Hofmann: J. Phys. IV France, 1997, vol. 7, pp. 383–88.

Y. Lee: Metall. Mater. Trans. A, 2002, vol. 33A, pp. 1913–17.

X. Tian and Y.S. Zang: Acta Metall. Sinica, 2003, vol. 16 (3), pp. 211–16.

P. Hohenberg and W. Kohn: Phys. Rev., 1964, vol. 136, pp. 864–71.

S. Kibey, J.B. Liu, M.J. Curtis, D.D. Johnson, and H. Sehitoglu: Acta Mater., 2006, vol. 54, pp. 2991–3001.

D. Finkenstadt and D.D. Johnson: Phys. Rev. B, 2006, vol. 73, paper no. 024101, pp. 1–10.

G. Lu, N. Kioussis, V.V. Bulatov, and E. Kaxsiras: Phys. Rev. B, 2000, vol. 62, pp. 3099–3108.

C. Cheng, R.J. Needs, V. Heine, and N. Churcher: Europhys. Lett., 1987, vol. 3, pp. 475–79.

A.P. Miodownik: Z. Metallkd., 1998, vol. 89, pp. 840–46.

S. Maggi and M. Murgia: Weld. Int., 2008, vol. 22 (9), pp. 610–18.

P.H. Adler, G.B. Olsen, and W.S. Owen: Metall. Trans. A, 1986, vol. 17A, pp. 1725–37.

D. Dew-Hughes and L. Kaufman: CALPHAD, 1979, vol. 3, pp. 175–203.

J.F. Breedis and L. Kaufman: Metall. Trans., 1971, vol. 2, pp. 2359–71.

L. Kaufman: CALPHAD, 1977, vol. 1, pp. 7–89.

D. Saulov: CALPHAD, 2006, vol. 30, pp. 405–14.

B. Lee: Metall. Trans. A, 1993, vol. 24A, pp. 1919–33.

A.T. Dinsdale: CALPHAD, 1991, vol. 15 (4), pp. 317–425.

X.J. Jin and T.Y. Hsu: Mater. Chem. Phys., 1999, vol. 61, pp. 135–38.

L. Li and T.Y. Hsu: CALPHAD, 1997, vol. 21 (3), pp. 443–48.

R. Ueji, N. Tsuchida, D. Terada, N. Tsuji, Y. Tanaka, A. Takemura, and K. Kunishige: Scripta Mater., 2008, vol. 59, pp. 963–66.

S.S. Babu, E.D. Specht, S.A. David, E. Karapetrova, P. Zschack, M. Peet, and H.K.D.H. Bhadeshia: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 3281–89.

C. Garcia de Andres, F.G. Caballero, C. Capdevila, and H.K.D.H. Bhadeshia: Scripta Mater., 2008, vol. 39 (6), pp. 791–96.

G.B. Olson and M. Cohen: Metall. Trans. A, 1976, vol. 7A, pp. 1897–1904.

S.M. Cotes, A. Fernandez Guillermet, and M. Sade: Metall. Mater. Trans. A., 2004, vol. 35A, pp. 83–91.

P.J. Ferreira and P. Müllner: Acta Mater., 1998, vol. 46 (13), pp. 4479–84.

K. Ishida: Scripta Metall., 1977, vol. 11, pp. 237–42.

B.K. Zuidema, D.K. Subramanyam, and W.C. Leslie: Metall. Trans. A, 1987, vol. 18A, pp. 1629–39.

A.S. Hamada, L.P. Karjalainen, M.C. Somani, and R.M. Ramadan: Mater. Sci. Forum, 2007, vol. 550, pp. 217–22.

M.R. Barnett: Scripta Mater., 2008, vol. 59, pp. 696–98.

H. Haddou, C. Gaudin, and X. Feaugas: J. Phys. IV France, 2001, vol. 11, pp. 283–91.

P. Hedström: Doctoral Thesis, Lulea University of Technology, Lulea, Sweden, 2007.

A.S. Hamada, L.P. Karjalainen, and M.C. Somani: Mater. Sci. Eng., A, 2007, vol. 467, pp. 114–24.

Acknowledgments

The authors gratefully acknowledge the financial support of the Deutsche Forschungsgemeinschaft (DFG) within the Collaborative Research Center (SFB) 761 “Steel–ab initio.” The assistance of H. Majedi, Department of Ferrous Metallurgy, RWTH Aachen University, for developing the required computer software, B. Hallstedt, Chair of Materials Chemistry, RWTH Aachen University, with the thermodynamics-based models, and A. Dick, Max-Planck-Institut für Eisenforschung (MPIE) (Düsseldorf, Germany), on the ab-initio techniques is deeply appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 23, 2009.

Rights and permissions

About this article

Cite this article

Saeed-Akbari, A., Imlau, J., Prahl, U. et al. Derivation and Variation in Composition-Dependent Stacking Fault Energy Maps Based on Subregular Solution Model in High-Manganese Steels. Metall Mater Trans A 40, 3076–3090 (2009). https://doi.org/10.1007/s11661-009-0050-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0050-8