Abstract

Armco Iron was severely deformed by means of a high-performance, high-pressure torsion (HPT) tool at a hydrostatic pressure of 5.4 GPa at low homologous temperatures, T m , between 0.08 and 0.40 T m . The flow stress was estimated from the measured torque during severe plastic deformation (SPD). At all investigated deformation conditions, a saturation in the flow stress at large strains without any decline was obtained. It is shown that this occurrence of a “steady state” at low homologous temperatures is significantly influenced by the deformation parameters, whereby an increase in deformation temperature or a decrease in strain rate results in a decrease in onset strain and an increase in flow stress in both the steady state and the size and aspect ratio of the structural elements. The Zener–Hollomon parameter is used to analyze the mechanical and microstructural properties as a function of the processing parameters; this shows that the investigated range of deformation conditions is divided into two regimes. For comparable high-deformation temperatures, the occurrence of a steady state is ascribed to a process similar to geometric dynamic recrystallization (DRX). Possible reasons for the occurrence of a different behavior in the low homologous temperature regime are discussed; the size of the crystallites formed during straining by the subdivision of the initial grains is considered to play an important role.

Similar content being viewed by others

Notes

Steady-state shear stress is obtained under the assumption that the material deformation was deformed during HPT in the burr zone, κ = 0. Additional details on the estimation of flow stress from torque curves measured during SPD are given in the Appendix.

References

R.Z. Valiev, R.K. Islamgaliev, I.V. Alexandrov: Prog. Mater. Sci., 2000, vol. 45, pp. 103–89

M.J. Zehetbauer, J. Kohout, E. Schafler: J. Alloys Compd., 2004, vol. 378, pp. 329–34

M. Zehetbauer: Acta Mater., 1993, vol. 41, pp. 589–99

Y. Iwahashi, Z. Horita, M. Nemoto: Acta Mater., 1998, vol. 46 (9), pp. 3317–31

B.Q. Han, S. Yue: Mater. Process. Technol., 2003, vol. 136, pp. 100–04

S.H. Lee, T. Sakai, D.H. Shin: Mater. Trans., 2003, vol. 44 (7), pp. 1382–85

A. Vorhauer, R. Pippan: Scripta Mater., 2004, vol. 51, pp. 921–25

C. Xu, M. Furukawa, Z. Horita: Acta Mater., 2003, vol. 51, pp. 6139–49

F.J. Humphreys, P.B. Prangnell, J.R. Bowen: Philos. Trans. R. Soc. London, Ser. A, 1999, vol. 357, pp. 1663–81

P.J. Apps, M. Berta, P.B. Prangnell: Acta Mater., 2005, vol. 53, pp. 499–511

D.H. Shin, B.D. Ahn, and H.S. Cho: in Ultrafine Grained Materials II, D.H. Shin and T.C. Lowe, eds., Minerals, Metals and Materials Society, Warrendale, PA, 2004, pp. 421–26.

N. Tsuji, Y. Ito, Y. Saito: Scripta Mater., 2002, vol. 47, pp. 893–99

D.H. Shin, J.J. Pak, Y.K. Kim: Mater. Sci. Eng., 2002, vol. 323, pp. 409–15

A. Vorhauer, S. Kleber, R. Pippan: Mater. Sci. Eng., A, 2005, vols. 410–411, pp. 281–84

R.Z. Valiev: Adv. Eng. Mater., 2003, vol. 5 (5), pp. 296–300

T. Hebesberger, H.P. Stüwe, A. Vorhauer, R. Pippan: Acta Mater., 2005, vol. 53, pp. 393–402

H.P. Stüwe: Adv. Eng. Mater., 2003, vol. 5, pp. 291–300

F. Wetscher: unpublished research, Hilti, Lichtenstein, 2005.

F. Wetscher and R. Pippan: Philos. Mag.., 2006, vol. 86, pp. 5867–83

W.H. Huang, C.Y. Yu, P.W. Kao: Mater. Sci. Eng., 2004, vol. 366, pp. 221–28

T. Sakai, J.J. Jonas: Acta Metall., 1984, vol. 32, pp. 189–209

S.J. Hales, T.R. McNelly, H.J. McQueen: Metall. Trans. A, 1991, vol. 22A, pp. 1037–47

K. Tsuzaki, X. Huang, T. Maki: Acta Mater., 1996, vol. 44, pp. 4491–99

F.J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, Pergamon Press, Oxford, 1996, pp. 127–392

S. Gourdet, F. Montheillet: Mater. Sci. Eng., A, 2000, vol. A283, pp. 274–88

H.J. McQueen, E. Evangelista, M.E. Kassner: Z. Metallkd., 1991, vol. 82, pp. 336–45

H.J. McQueen, E. Evangelista: Czech. J. Phys., B, 1988, vol. 38, pp. 359–72

A. Belyakov, T. Sakai, H. Miura: ISIJ Int., 1999, vol. 39, pp. 592–99

A. Belyakov, T. Sakai, H. Miura: Acta Mater., 2002, vol. 50, pp. 1547–57

M.E. Kassner, H.J. McQueen, E. Evangelista: Mater. Sci. Forum, 1993, vols. 113–115, pp. 151–56

N. Tsuji, R. Ueji, and Y. Ito: Proc. 21st Riso Int. Symp. on Materials Science, Riso National Laboratory, Denmark, 200, pp. 105–14.

M.R. Druby, F.J. Humphreys: Acta Metall., 1986, vol. 34, pp. 2259–71

P. Cizek, B.P. Wynne: Mater. Sci. Eng., A, 1997, vol. 230, pp. 88–94

A. Belyakov, R. Kaibyshev, R. Zaripova: Mater. Sci. Forum, 1993, vols. 113–115, pp. 385–89

C.G. Schmidt, C.M. Young, B. Walser: Metall. Trans. A, 1982, vol. 13A, pp. 447–56

H.J. McQueen, W.A. Wong, J.J. Jonas: Can. J. Phys., 1967, vol. 45, pp. 1225–39

W.A. Wong, J.J. Jonas: Trans. TMS-AIME, 1968, vol. 242, pp. 2271–80

H.J. McQueen, N. Ryum: Scand. J. Metall., 1985, vol. 14, pp. 183–94

H.J. McQueen, W. Blum: Mater. Sci. Eng., A, 2004, vol. 290, pp. 95–107

J. Philibert: Atom Movements—Diffusion and Mass Transport in Solids, Number 110, Les Editions de Physique, Les Ulis, France, 1991, pp. 74–81.

D.W. James, G.M. Leak: Philos. Mag., 1966, vol. 14, pp. 701–13

H.J. Frost and M.F. Ashby: Deformation-Mechanism Maps—The Plasticity and Creep of Metals and Ceramics, Pergamon Press, Oxford, 1982, pp. 60–74.

H.J. McQueen, J.K. Solberg, N. Ryum: Philos. Mag. A, 1989, vol. 60, pp. 447–71

G. Glover, C.M. Sellars: Metall. Trans., 1973, vol. 4, pp. 765–75

F. Schuh, M. von Heimendahl: Z. Metallkd., 1974, vol. 65, pp. 346–52

A. Korbel, M. Richer, J. Richert: Deformation in Polycrystals: Mechanism and Microstructures, Riso National Laboratory, Roskilde, Denmark, 1981, pp. 445–50

H. Hero, C.J. Simenson: Scand. J. Metall., 1972, vol. 1, pp. 115–20

E.V. Kozlov, A.N. Zhdanov, N.A. Popova: Mater. Sci. Eng., A, 2004, vols. A387–A389, pp. 789–94

Y. Huang, T.G. Langdon: Mater. Sci. Eng., A, 2003, vol. 358, pp. 114–21

R.Z. Valiev, Y.V. Ivanishenko, E.F. Rauch: Acta Mater., 1996, vol. 44, pp. 4705–12

S. Takaki, K. Kawasaki, Y. Kimura: Mater. Process. Technol., 2001, vol. 117, pp. 359–63

B. Derby: Acta Metall. Mater., 1991, pp. 955–62.

H.P. Stüwe, H. Turk: Z. Metallkd., 1964, vol. 55, pp. 699–703

M. Zhou, M.P. Clode: Mech. Mater., 1998, vol. 27, pp. 63–76

F. Wetscher, A. Vorhauer, R. Pippan: Mater. Sci. Eng., A, 2005, vols. 410–411, pp. 213–16

D.S. Fields and A.W. Backofen: in Proc. ASTM, 1957, vol. 57, pp. 1259–72.

W. Ecker: Master’s thesis, University of Leoben, Austria, 2004.

Acknowledgments

The financial support of the Christian Doppler Forschungsgesellschaft and the Fonds zur Förderung der wissenschaftlichen Forschung (Project No. P17096N02) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 7, 2006.

Appendix

Appendix

Measurement of flow stress during HPT

For a conventional torsion test, the shear flow stress τ(γ) is generally integrated over the cross sections to equilibrate with the applied torque,[53–55] Γ t (γ):

where a is the radius at the circumference of the sample. The extraction of the flow stress from Eq. [A1] can be made at the circumference of the sample.[53,56] If only the saturation is of further interest rather than the detailed hardening behavior of the material, as is the case in the present study, then the saturation shear flow stress τ s is given as

where Γ t,s is the measured saturation torque.

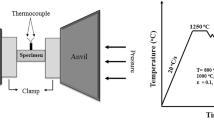

The torque measured in situ during HPT reflects the change of the flow stress of the processed materials at the given parameters shear strain γ, strain rate \( \ifmmode\expandafter\dot\else\expandafter\.\fi{\gamma } \), and deformation temperature T. Due to the geometry of the HPT tool used in the present study (Figure A1), the measured torque Γ consists of the torque Γ d needed for the torsional deformation of the material in the cavity between the two anvils (deformation zone, \( 0 \le r < r_{i} \)) and a torque Γ b that arises in the area of the burr (burr zone, \( r_{i} \le r < r_{o} \)) that is formed during the loading of the tool before one of the anvils starts to rotate with respect to the other one. The saturation shear flow stress is then calculated by

where Γ d,s represents the saturation torque arising in the deformation zone. This torque is calculated by subtracting the saturation torque arising in the burr zone Γ b,s from the totally measured torque Γ s at saturation:

Detailed sketch of the used tool with cavity zone and the area of the burr[25]

Depending on the behavior of the materials in the burr zone, the following two cases for the contribution of the burr to the totally measured torque can be distinguished.

1.1 A. Sliding between Burr and Tool

Assuming that slip between one side of the burr and the anvil is present, the torque arising in this area is given with

where r i and r o are the radii of the inner and the outer edge of the burr, p(r) describes the pressure in the burr zone as a function of the radius, r is the distance to the center of rotation, and μ represents the coefficient of friction. Recent results from finite element calculations[57] make it reasonable to assume for the given HPT tool a linear decrease from about 80 pct of the nominal hydrostatic pressure at the inner edge to the flow stress of the undeformed material at the outer edge of the burr. For this type of linear drop of pressure in the burr zone, the torque arising in this region is given by

1.2 B. Deformation of the Materials That Form the Burr

In the case in which friction is sufficient to deform the material in the burr zone, the saturation torque arising in this area is given by

where τ b,s is the saturation flow stress in the burr zone. Due to the geometry of the tool, the strain rate in the burr zone is larger than in the deformation zone, which conventionally increases the flow stress in this area a little; this is expressed as \( \tau _{{b,d,s}} \simeq {\left( {1 + \kappa } \right)}\tau _{s} \), where κ is a very small number, depending on the difference in strain rate between the deformation zone, the burr zone, and the processed material. The contribution of the burr zone to the total torque can then be expressed as a constant fraction, f b , which is calculated as

The torque from the burr zone can then be expressed as

The effect in the variation of the friction coefficient of sliding, μ, and the steady-state stress increase due to the higher strain rate in the burr regions on the estimation of the steady-state flow stress is illustrated in Figure A2 by the fraction of the corrected steady-state flow stress, τ s , and the uncorrected flow stress, τ s,uncorrected, determined from the measured torque. Assuming deformation of the material in the burr, the flow stress is only influenced by the parameter κ. In contrast, the flow stress determined under the assumptions of the sliding of the material in the burr against one of the anvils is much more affected by the chosen coefficient of friction. In addition, τ s /τ s,uncorrected depends on τ s and, therefore, on Γ s itself. An increase in Γ s reduces the difference between τ s and τ s,uncorrected.

Comparison of the fraction of corrected and uncorrected steady-state flow stress obtained from in-situ torque measurements during HPT, under the assumptions of sliding of the material that forms the burr against one anvil (dashed lines) and deformation of the burr material (solid line), respectively. See text for further description[26]

Rights and permissions

About this article

Cite this article

Vorhauer, A., Pippan, R. On the Onset of a Steady State in Body-Centered Cubic Iron during Severe Plastic Deformation at Low Homologous Temperatures. Metall Mater Trans A 39, 417–429 (2008). https://doi.org/10.1007/s11661-007-9413-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-007-9413-1