Abstract

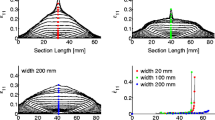

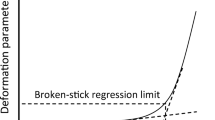

A heterogeneous finite element model with randomly distributed inhomogeneities has been developed for the determination of the forming limit diagram (FLD) for thin aluminum sheet material based on the prediction of localized necking. The strength difference between the inhomogeneities and the matrix is ascertained either from the fluctuation of the experimental stress-strain curve or from a micromechanical analysis that uses a representative particle field. By changing the specimen geometry and friction conditions, different stress states (or strain paths) are achieved. A plot of the critical Oyane fracture parameter is used to identify the limit strain state. Also, a plot of equivalent plastic strain rate is used to distinguish the boundary of intense shear bands and hence to identify where to take the measurement point. Both a plane stress model and a three-dimensional (3-D) model are adopted to predict the shear banding phenomenon and hence the FLD. The predicted FLD agrees well with the measurements from a recent round robin experimental FLD involving several independent research laboratories. The Taguchi method is applied to assess how the various parameters involved in the heterogeneous model affect the calculated forming limit strain.

Similar content being viewed by others

References

K. Narasimhan and R.H. Wagoner: Metall. Trans. A, 1991, vol. 22, pp. 2655–65.

M. Jain, D.J. Lloyd, and S.R. MacEwen: Int. J. Mech. Sci., 1996, vol. 38, pp. 219–32.

P.D. Wu, K.W. Ncale, and E. Van der Giessen: Proc. R. Soc. London, Ser. A: Math., Phys. Eng. Sci., 1997, vol. 453, pp. 1831–48.

H.P. Gänser, E.A. Werner, and F.D. Fischer: Int. J. Mech. Sci. 2000, vol. 42, pp. 2041–54.

P.D. Wu, S.R. MacEwen, D.J. Lloyd, and K.W. Neale: Modell. Simul. Mater. Sci. Eng., 2004, vol. 12, pp. 511–27.

K. Inal, K.W. Neale, and A. Aoutajeddine: Int. J. Plast., 2005, vol. 21, pp. 1255–66.

K. Janssens, F. Lambert, S. Vanrostenberghe, and M. Vermeulen: J. Mater. Process. Technol., 2001, vol. 112, pp. 174–84.

R. Hill: J. Mech. Phys. Solids, 1952, vol. 1, pp. 19–30.

X. Duan, M. Jain, D. Metzger, J. Kang, D.S. Wilkinson, and J.D. Embury: Mater. Sci. Eng., A, 2005, vol. 394, pp. 192–203.

W. Hotz: GOM User Meeting, Braunschweig, Germany, 2004.

K. Nakajima, T. Kikuuma, and K. Hasuka: “Yawata Technical Report No. 284”, Yawata, Japan, 1971, pp 678–90.

W.Y. Fowlkes and C.M. Creveling: Engineering Methods for Robust Product Design Using Taguchi Methods in Technology and Product Development, Addison-Wesley, Reading, MA, 1995.

D.R. Metzger, X. Duan, and M. Jain: Paper presented at the American Society of Mechanical Engineers, Pressure Vessels and Piping Division, Denver, CO, July 17–21, 2005, Paper Number PVP2005-71383.

M. Moore and P. Bate: J. Mater. Process. Technol., 2002, vols. 125–26, pp. 258–66.

E. Voce: J. Inst. Met., 1948, vol. 74, pp. 537–62.

M. Oyane, T. Sato, K. Okimoto, and S. Shima: J. Mech. Working Technol., 1980, vol. 4, pp. 65–81.

X. Duan, M. Bruhis, M. Jain, and D.S. Wilkinson: Adv. Mater. Res., 2005, vol. 66, pp. 737–44.

ARAMIS 4.7, GOM mbH, Braunschweig, Germany, 2001.

X. Duan, Y. Osokov, M. Jain, D.R. Metzger, and D.S. Wilkinson: unpublished report, McMaster University, Hamilton, Canada, 2005.

C. Liu: Exp. Mech., 2005, vol. 45, pp. 238–43.

Z.Y. Ren and Q.S. Zheng: J. Mech. Phys. Solids, 2002, vol. 50, pp. 881–93.

P.D. Wu and D.J. Lloyd: Acta Mater., 2004, vol. 52, pp. 1785–98.

F. Barlat, D.J. Ledge, and J.C. Brem: Int. J. Plast., 1991, vol. 7, pp. 693–712.

F. Barlat, J.C. Brem, J.W. Yoon, K. Chung, R.E. Dick, D.J. Lege, F. Pourboghrat, S.H. Choi, and E. Chu: Int. J. Plast., 2003, vol. 19, pp. 1297–319.

Z. Marciniak and K. Kuczynski: Int. J. Mech. Sci., 1967, vol. 9, pp. 609–20.

A.L. Gurson: J. Eng. Mater. Technol., 1977, vol. 99, pp. 2–15.

V. Tvergaard and A. Needleman: Acta Metall., 1984, vol. 32, pp. 461–90.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Duan, X., Jain, M. & Wilkinson, D.S. Development of a heterogeneous microstructurally based finite element model for the prediction of forming limit diagram for sheet material. Metall Mater Trans A 37, 3489–3501 (2006). https://doi.org/10.1007/s11661-006-1044-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-1044-4