Abstract

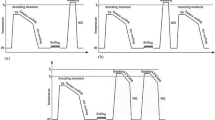

The effects of a recently developed interrupted aging procedure on the microstructural development and mechanical properties of the commercial Al-Mg-Si-Cu alloy 6061 have been studied using transmission electron microscopy (TEM), differential scanning calorimetry (DSC), and mechanical testing. This so-called T6I6 temper involves partially aging the alloy at a typical T6 temperature (the underaging stage), quenching, then holding at a reduced temperature (in this case 65 °C) to facilitate further hardening (the secondary aging stage), prior to final aging to peak properties at, or close to, the initial aging (T6) temperature (the reaging stage). The T6I6 aging treatment produces simultaneous increases in tensile properties, hardness, and toughness, as compared with conventional T6. The overall improvement in the mechanical properties of 6061 T6I6 is associated with the formation of a greater number of finer, and more densely dispersed, β″ precipitates in the final microstructure. Secondary precipitation took place during the interrupted aging stage of the T6I6 temper, resulting in the formation of a large number of Guinier-Preston (GP) zones that served as precursors to the needlelike β″ precipitates when elevated temperature aging was resumed.

Similar content being viewed by others

References

R.N. Lumley, I.J. Polmear, and A.J. Morton: Australian Patent AU766929, 2004.

R.N. Lumley, I.J. Polmear, and A.J. Morton: Mater. Sci. Forum, 2002, vols. 396–402, pp. 893–98.

R.N. Lumley, I.J. Polmear, and A.J. Morton: Mater. Sci. Technol., 2005, vol. 29 (9), pp. 1025–32.

R.N. Lumley, I.J. Polmear, and A.J. Morton: International Patent Application PCT/AU02/00234, 2002.

R.N. Lumley, I.J. Polmear, and A.J. Morton: Mater. Sci. Technol., 2003, vol. 19 (11), pp. 1483–90.

H. Löffer: Structure and Development of Al-Zn Alloys, Akademie Verlag, Berlin, 1995, pp. 250–66.

H. Löffler, I. Kovacs, and J. Lendvai: J. Mater. Sci., 1983, vol. 18, pp. 2215–21.

M.J. Starink, A.J. Hobson, I. Sinclair, and P.J. Gregson: Mater. Sci. Eng. A, 2000, vol. 289, pp. 130–42.

R.N. Lumley, I.J. Polmear, and A.J. Morton: Acta Mater., 2002, vol. 50, pp. 3597–608.

R.G. O’Donnell, R.N. Lumley, and I.J. Polmear: Proc. 9th Int. Conf. on Aluminium Alloys, Brisbane, Australia, 2004, pp. 975–80.

I. Dutta and S.M. Allen: J. Mater. Sci. Lett., 1991, vol. 10, pp. 323–26.

G.A. Edwards, K. Stiller, G.L. Dunlop, and M.J. Couper: Acta Mater., 1998, vol. 46, pp. 3898–3904.

D.E. Laughlin and W.F. Miao: Automotive Alloys II, TMS, Warrendale PA, 1998, pp. 63–79.

D.J. Chakrabarti, B.K. Cheong, and D.E. Laughlin: Automotive Alloys II, TMS, Warrendale, PA, 1998, pp. 27–44.

D.J. Chakrabarti and D.E. Laughlin: Progr. Mater. Sci., 2004, vol. 49, pp. 389–410.

M. Murayama and K. Hono: Acta Mater., 1999, vol. 47, pp. 1537–48.

M. Murayama, K. Hono, M. Saga, and M. Kikuchi: Mater. Sci. Eng. A, 1998, vol. 250, pp. 127–32.

M. Takeda, F. Ohkubo, and T. Shirai: J. Mater. Sci, 1998, vol. 33, pp. 2385–90.

L. Zhen and S.B. Kang: Mater. Sci. Technol., 1998, vol. 14, pp. 317–23.

C.D. Marioara, S.J. Andersen, J. Jansen, and H.W. Zandbergen: Acta Mater., 2003, vol. 51, pp. 789–96.

S.D. Dumolt, D.E. Laughlin, and J.C. Williams: Scripta Metall., 1984, vol. 18, pp. 1347–52.

K. Matsuda, Y. Uteani, T. Sato, and S. Ikeno: Metall. Trans. A, 2001, vol. 32, pp. 1293–99.

S.J. Andersen: Metall. Trans. A, 1995, vol. 26, pp. 1931–37.

J.W. Martin: Precipitation Hardening, 2nd ed., Butterworth-Heinemann, Oxford, United Kingdom, 1998, pp. 78–125.

J. Buha: Ph.D. Thesis, University of New South Wales, Sydney, 2005, http://adt.caul.edu.au/, pp. 234–76.

J.F. Nie, B.C. Muddle, and I.J. Polmear: Mater. Sci. Forum, 1996, vols. 217–222, pp. 1257–62.

D.W. Pashley, J.W. Rhodes, and A. Sendorek: J. Inst. Met., 1966, vol. 94, pp. 41–47.

D.W. Pashley, M.H. Jacobs, and J.T. Vietz: Phil. Mag., 1967, vol. 16, pp. 51–63.

I.J. Polmear: Light Alloys: from Traditional Alloys to Nanocrystals, 4th ed., Butterworth-Heinemann Publishers, Oxford, United Kingdom, 2006, p. 141.

J. Buha, P.R. Munroe, R.N. Lumley, A.G. Crosky, and A.J. Hill: Proc. 9th Int. Conf. on Aluminium Alloys, Brisbane, Australia, 2004, pp. 1028–33.

R. Ferragut, A. Somoza, A. Dupasquier, and I.J. Polmear: Mater. Sci. Forum, 2002, vols. 396–402, pp. 777–82.

C.E. Macchi, A. Somoza, A. Dupasquier, and I.J. Polmear: Acta Mater., 2003, vol. 51, pp. 5151–58.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Buha, J., Lumley, R.N. & Crosky, A.G. Microstructural development and mechanical properties of interrupted aged Al-Mg-Si-Cu alloy. Metall Mater Trans A 37, 3119–3130 (2006). https://doi.org/10.1007/s11661-006-0192-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-0192-x