Abstract

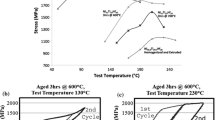

The objective of this study is to examine fundamental processing-structure-property relationships in polycrystalline NiTi bars. Three different polycrystalline Ti-50.9 at. pct Ni (Ti-55.7 wt pct Ni) materials were examined: (1) cast, (2) cast then hot rolled, and (3) cast, hot rolled, then cold drawn. The structure of the materials was investigated at various scales ranging from nanometers to micrometers. The cast materials contained random crystallographic textures along the loading axis of the extracted samples. The hot-rolled and cold-drawn materials contained a strong 〈111〉 texture parallel to the deformation-processing direction. The high-temperature hot-rolling process facilitated recrystallization and recovery, and curtailed precipitate formation, leaving the hot-rolled and cold-drawn materials in near solutionized states. The cold-drawn material contained a high density of dislocations and martensite. After a mild aging treatment, all three materials contained distributed coherent Ti3Ni4 precipitates on the order of 10 nm in size. The cast material was capable of full shape-memory transformation strain recovery up to approximately 5 pct strain at room temperature under both tension and compression. The hot-rolled and cold-drawn materials demonstrated significant tension-compression stress-strain asymmetry owing to their strong crystallographic texture. Under compression, the deformation-processed materials were only capable of 3 pct transformation strain recovery while under tension they were capable of nearly 7 pct transformation strain recovery. Based on the present results, the presence of small coherent Ti3Ni4 precipitates is determined to be the driving force for the favorable strain transformation strain recovery properties in all three materials, despite drastically different grain sizes and crystallographic textures. The unique dependence of elastic modulus on stress-state, temperature, and structure is also presented and discussed for the deformation-processed materials. In addition, we demonstrate that the appearance of a Lüders band transformation under tensile loading can be controlled by material structure. Specifically, the presence of significant martensite and dislocations in the cold-drawn materials was shown to mitigate the Lüders band propagation and result in a more gradual transformation.

Similar content being viewed by others

References

R. DesRoches and M. Delemont: Eng. Struct., 2002, vol. 24, pp. 325–32.

C.A. Rogers: J. Intelligent Mater. Systems Struct., 1995, vol. 6, pp. 4–12.

Y. Liu, Z.L. Xie, J. Van Humbeeck, and L. Delaey: Acta Mater., 1999, vol. 47, pp. 645–60.

S. Miyazaki, V.H. No, K. Kitamura, A. Khantachawana, and H. Hosoda: Int. J. Plasticity, 2000, vol. 16, pp. 1135–54.

H. Sehitoglu, I. Karaman, R. Anderson, X. Zhang, K. Gall, H.J. Maier, and Y. Chumlyakov: Acta Mater., 2000, vol. 48, pp. 3311–26.

J.M. Legresy, B. Prandi, and G.M. Raynaud: J. Phys. IV, 1991, vol. 1, pp. C4 241-C4 246.

D.N. Abujudom, P.E. Thoma, and S. Fariabi: Mater. Sci. Forum, 1990, vols. 56–58, pp. 565–70.

K. Johansen, H. Voggenreiter, and G. Eggeler: Mater. Sci. Eng., 1999, vols. A273-A275, pp. 410–14.

W. Tang, B. Sundman, R. Sandström, and C. Qiu: Acta Mater., 1999, vol. 47, pp. 3457–68.

P. Filip and K. Mazanec: Scripta Metall. Mater., 1995, vol. 32, pp. 1375–80.

T. Todoroki and H. Tamura: Trans. Jpn. Inst. Met., 1987, vol. 28, pp. 83–94.

D. Treppmann and E. Hornbogen: J. Phys. IV, 1997, vol. 7, pp. C5 211-C 220.

D. Treppmann and E. Hornbogen: J. Phys. IV, 1995, vol. 5, pp. C2 211-C 216.

P. Filip, J. Rusek, and K. Mazanec: Z. Metallkd., 1991, vol. 82, pp. 488–91.

H.C. Lin and S.K. Wu: Mater. Sci. Eng., 1992, vol. A158, pp. 87–91.

W. Siegert, K. Neuking, M. Mertmann, and G. Eggeler: Mater. Sci. Forum., 2002, vols. 394–395, pp. 361–64.

J.K. Allafi, A. Dlouhy, K. Neuking, and G. Eggeler: J. Phys. IV, 2001, vol. 11, pp. PR8 529-PR8 534.

K. Gall, T. Jesse Lim, D.L. McDowell, H. Sehitoglu, and Y.I. Chumlyakov: Int. J. Plasticity, 2000, vol. 16, pp. 1189–1214.

I. Lee, A.K. Ghosh, R. Ray, and S. Jha: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 2017–26.

K.J. Bowman, J. Jenny, and S. Kim: Mater. Sci. Eng., 1993, vol. A160, pp. 201–08.

D. Raabe and J. Keichel: J. Mater. Res., 1996, vol. 11, pp. 1694–1701.

W.Q. Yuan, and S.Q. Yang: J. Mater. Sci. Lett., 2002, vol. 21, pp. 443–45.

K. Gall and H. Sehitoglu: Int. J. Plasticty, 1999, vol. 15, pp. 69–92.

K. Gall, H. Sehitoglu, Y.I. Chumlyakov, and I.V. Kireeva: Acta Mater., 1999, vol. 47, pp. 1203–17.

K. Gall, H. Sehitoglu, R. Anderson, I. Karaman, Y.I. Chumlyakov, and I.V. Kireeva: Mater. Sci. Eng., 2001, vol. A317, pp. 85–92.

L. Orgéas and D. Favier: Acta Mater., 1998, vol. 46, pp. 5579–91.

L. Orgéas and D. Favier: J. Phys. IV, 1995, vol. 5, pp. C8 605-C8 610.

R. Plietsch and K. Ehrlich: Acta Mater., 1997, vol. 45, pp. 2417–24.

T. Duerig, A. Pelton, and D. Stöckel: Mater. Sci. Eng., 1999, vol. A273–A275, pp. 149–60.

D. Treppmann, E. Hornbogen, and D. Wurzel: J. Phys. IV, 1995, vol. 5, pp. C8 569-C8 574.

P. Filip and K. Mazanec: Scripta Mater., 2001, vol. 45, pp. 701–07.

J. Kim, Y. Liu, and S. Miyazaki: Acta Mater., 2004, vol. 52, pp. 487–99.

S. Miyazaki, Y. Ohmi, K. Otsuka, and Y. Suzuki: J. Phys. IV, 1982, vol. 43, pp. C4 255-C4 260.

K. Gall and H.J. Maier: Acta Mater., 2002, vol. 50, pp. 4643–57.

J.S. Kallend, U.F. Kocks, A.D. Rollett, and H.R. Wenk: Mater. Sci. Eng., 1991, vol. A132, pp. 1–11.

M. Kompatscher, B. Deme, G. Kostorz, C. Somsen, and E.F. Wassermann: Acta Mater., 2002, vol. 50, pp. 1581–86.

C. Somsen: Ph.D. Thesis, University Duisburg, Shaker Verlag, Aachen, 2002.

E. Hornbogen: Mater. Sci. Eng., 1999, vols. A273–A275, pp. 630–33.

P.S. Khadkikar, G.M. Michal, and K. Vedula: Metall. Trans. A, 1990, vol. 21A, pp. 279–88.

S. Miyazaki, K. Ostsuka, and C.M. Wayman: Acta Mater., 1989, vol. 37, pp. 1873–84.

S. Miyazaki, K. Ostsuka, and C.M. Wayman: Acta Mater., 1989, vol. 37, pp. 1885–90.

J.R. Davis, D. Hodgson, M. Wu, and R. Biermann: ASM Handbook, 10th ed., ASM INTERNATIONAL, Materials Park, OH, 1990, vol. 2, p. 899.

J. Shaw and S. Kyriakides: Acta Mater., 1997, vol. 45, p. 683.

A. Heckman and E. Hornbogen: Mater. Sci. Forum, 2002, vols. 394–395, pp. 325–28.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Frick, C.P., Ortega, A.M., Tyber, J. et al. Multiscale structure and properties of cast and deformation processed polycrystalline NiTi shape-memory alloys. Metall Mater Trans A 35, 2013–2025 (2004). https://doi.org/10.1007/s11661-004-0150-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-004-0150-4