Abstract

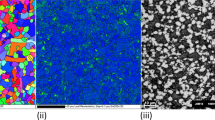

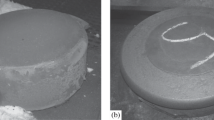

Two powder metallurgy nickel-base turbine disk alloys, RENE’95* and KM4, were studied for strength and deformation behavior at 650 °C. Two classes of microstructures were investigated: unimodal size distributions of γ′ precipitates with particle sizes ranging from 0.1 to 0.7 µm and commercially heat-treated structures with bimodal or trimodal size distributions of γ′ precipitates. The strength and deformation mechanisms were heavily influenced by the microstructure. In both alloys, deformation during compression tests consisted of a combination of a/2〈110〉 antiphase boundary (APB)-connected dislocation pairs and a/3〈112〉 partials creating superlattice intrinsic stacking faults (SISFs). In unimodal alloys, the fault density increased with decreasing particle size and decreasing strain rate. These trends, observed in compression testing, are consistent with earlier studies of similar alloys, which were tested in creep. As the γ′ size was reduced, the nature of the faults changed from being isolated within single precipitates to being extended across entire grains. Commercially heat-treated alloys, containing a bimodal distribution of γ′ particles, exhibited significantly more faulting than unimodal alloys at the same cooling γ′ size. This augmentation of the faulting in commercial alloys was apparently due to the presence of the fine, aging γ′ particles. The two typical commercial heat treatments (supersolvus and subsolvus) resulted in different deformation structures: the subsolvus behavior was similar to that of unimodal alloys with γ′ sizes between 0.2 and 0.35 µm, while the supersolvus deformation was similar to that of unimodal alloys with the 0.1 µm γ′ size. These differences were attributed to differences in the size of the fine, aging γ′ particles. Creep deformation in a commercially heat-treated material at 650 °C occurred solely by SISF-related mechanisms, resulting in a macroscopic slip vector of 〈112〉. The effects of alloy chemistry, APB energy, and microstructure on the deformation and mechanical behavior are discussed in detail, and possible effects of the faulting mechanisms on the mechanical behavior are explored. Finally, models for yield strength as a function of microstructure for bimodal alloys with large volume fractions of precipitates are found to be in need of development.

Similar content being viewed by others

References

D.D. Krueger, J.F. Wessels, and K-M. Chang: U.S. Patent 5,143,563, Sept. 1, 1992.

E.S. Huron: GE Aircraft Engines, Evendale OH, private communication, 1996.

I.M. Lifshitz and V.V. Slyozov: J. Phys. Chem. Solids, 1961, vol. 19, pp. 35–50.

C. Wagner: Z. Elektrochem., 1961, vol. 65, pp. 581–91.

A.J. Ardell: Proc. Int. Symp. on Mechanisms of Phase Transformations in Crystalline Solids, Institute of Metals Monograph and Report Series, 1968, pp. 111–16.

R.A. MacKay and M.V. Nathal: Acta Metall. Mater., 1990, vol. 38, pp. 993–1005.

H.A. Calderon, P.W. Voorhees, J.L. Murray, and G. Kostorz: Acta Metall. Mater., 1993, vol. 42, pp. 991–1000.

D.B. Williams and C.B. Carter: Transmission Electron Microscopy, Plenum Press, New York, NY, 1996, pp. 385–87.

A.J. Huis in’t Veld, G. Boom, P.M. Bronsveld, and J.T.M. de Hosson: Scripta Metall., 1985, vol. 19, pp. 1123–28.

M. Condat and B. Décamps: Scripta Metall., 1987, vol. 21, pp. 607–12.

P. Caron, T. Khan, and P. Veyssière: Phil. Mag. A, 1988, vol. 57, pp. 859–75.

R. Bonnet and A. Ati: Acta Metall., 1989, vol. 37, pp. 2153–69.

P.R. Bhowal, E.F. Wright, and E.L. Raymond: Metall. Trans. A, 1990, vol. 21A, pp. 1709–17.

W.W. Milligan and S.D. Antolovich: Metall. Trans. A, 1991, vol. 22A, pp. 2309–18.

D. Mukherji, F. Jiao, W. Chen, and R.P. Wahi: Acta Metall., 1991, vol. 39, pp. 1515–24.

T. Link and M. Feller-Kniepmeier: Metall. Trans. A, 1992, vol. 23A, pp. 99–105.

G.R. Leverant and B.H. Kear: Metall. Trans., 1970, vol. 1, pp. 491–98.

R.A. MacKay and R.D. Maier: Metall. Trans. A, 1982, vol. 13A, pp. 1747–54.

W.W. Milligan and S.D. Antolovich: Metall. Trans. A, 1989, vol. 20A, pp. 1888–89.

E. Nembach: Particle Strengthening of Metals and Alloys, Wiley and Sons, New York, NY, 1997.

S.M. Copley and B.H. Kear: Trans. TMS-AIME, 1967, vol. 239, pp. 984–92.

A.J. Ardell, V. Munjal, and D.J. Chellman: Metall. Trans. A, 1976, vol. 7A, pp. 1263–68.

B. Reppich: Acta Metall., 1982, vol. 30, pp. 87–94.

B. Reppich, P. Schepp, and G. Wehner: Acta Metall., 1982, vol. 30, pp. 95–104.

E. Nembach, S. Schänzer, W. Schröer, and K. Trinckauf: Acta Metall., 1988, vol. 36, pp. 1471–79.

S. Schänzer and E. Nembach: Acta Metall. Mater., 1992, vol. 40, pp. 803–13.

A. Nitz and E. Nembach: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 799–807.

A. Nitz and E. Nembach: Mater. Sci. Eng., 1999, vol. A263, pp. 15–22.

B. Reppich, W. Kuhlein, G. Meyer, D. Puppel, M. Schulz, and G. Schumann: Mater. Sci. Eng., 1986, vol. 83, pp. 45–63.

D.J. Chellman, A.J. Luévano, and A.J. Ardell: Proc. 9th Int. Conf. on the Strength of Metals and Alloys, D.G. Brandon, R. Chaim, and A. Rosen, eds., Freund Publishing House, London, 1991, vol. 1, p. 537.

R.N. Jarrett and J.K. Tien: Metall. Trans. A, 1982, vol. 13A, pp. 1021–32.

J.P. Collier, P.W. Keefe, and J.K. Tien: Metall. Trans. A, 1986, vol. 17A, pp. 651–61.

B.H. Kear and D.P. Pope: Refractory Alloying Elements in Superalloys, J.K. Tien and S. Reichman, eds., ASM, Metals Park, OH, 1984, pp. 135–51.

L.R. Curwick: Ph.D. Thesis, University of Minnesota, Minneapolis, MN, 1972.

K. Suzuki, M. Ichihara, and S. Takeuchi: Acta Metall., 1979, vol. 27, pp. 193–200.

Author information

Authors and Affiliations

Additional information

RENE′95 is a trademark of General Electric Company, Fairfield, CT.

Rights and permissions

About this article

Cite this article

Sinharoy, S., Virro-Nic, P. & Milligan, W.W. Deformation and strength behavior of two nickel-base turbine disk alloys at 650 °C. Metall Mater Trans A 32, 2021–2032 (2001). https://doi.org/10.1007/s11661-001-0014-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0014-0