Abstract

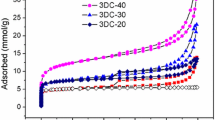

A convenient and cost-effective flame approach to produce a silica template with a unique structure was proposed. The hierarchical porous carbon materials (PCMs) fabricated employing presently prepared silica provide a high specific surface area for the diffusion of Li ions and transportation of electrons. Analysis of nitrogen absorption-desorption and pore size distribution (PSD) shows that PCMs possess plenty of micropores, mesopores, and macropores. Benefiting from the cooperation of various-sized pores, the PCMs-700 as anode material for lithium-ion batteries (LIBs) exhibits outstanding reversible capacities of 1332 mAh g−1 at current density of 37.2 mA g−1 (0.1 C) and 834 mAh g−1 at 372 mA g−1 (1 C). And when the current density is increased to 3.72 A g−1 (10 C), it could still retain reversible capacity of 430 mAh g−1. This result suggests that the hierarchical porous carbon material would be a promising anode material in the LIBs.

Similar content being viewed by others

References

Tarascon JM, Armand M (2001) Issues and challenges facing rechargeable lithium batteries. Nature 414:359–367. doi:10.1142/9789814317665_0024

Bhardwaj T, Antic A, Pavan B, Barone V, Fahlman BD (2010) Enhanced electrochemical lithium storage by graphene nanoribbons. J Am Chem Soc 132:12556–12558. doi:10.1021/ja106162f

Armand M, Tarascon JM (2008) Building better batteries. Nature 451:652–657. doi:10.1038/451652a

Ji L, Lin Z, Alcoutlabi M, Zhang X (2011) Recent developments in nanostructured anode materials for rechargeable lithium-ion batteries. Energy Environ Sci 4:2682–2699. doi:10.1039/C0EE00699H

Levi MD, Aurbach D (1997) Diffusion coefficients of lithium ions during intercalation into graphite derived from the simultaneous measurements and modeling of electrochemical impedance and potentiostatic intermittent titration characteristics of thin graphite electrodes. J Phys Chem B 101:4641–4647. doi:10.1021/jp9701911

Palacin MR (2009) Recent advances in rechargeable battery materials: a chemist’s perspective. Chem Soc Rev 38:2565–2575. doi:10.1039/B820555H

Ji L, Zhang X (2009) Fabrication of porous carbon nanofibers and their application as anode materials for rechargeable lithium-ion batteries. Nanotechnology 20:155705. doi:10.1088/0957-4484/20/15/155705

Morris RS, Dixon BG, Gennett T, Raffaelle R, Heben MJ (2004) High-energy, rechargeable Li-ion battery based on carbon nanotube technology. J Power Sources 138:277–280. doi:10.1016/j.jpowsour.2004.06.014

Yoo E, Kim J, Hosono E, Zhou H, Kudo T, Honma I (2008) Large reversible Li storage of graphene nanosheet families for use in rechargeable lithium-ion batteries. Nano Lett 8:2277–2282. doi:10.1021/nl800957b

Ren JG, He XM, Wang K, Pu WH (2010) The impact of carbon shell on a Sn–C composite anode for lithium-ion batteries. Ionics 16:503–507. doi:10.1007/s11581-010-0435-0

Cheng FY, Tao ZL, Liang J, Chen J (2008) Template-directed materials for rechargeable lithium-ion batteries. Chem Mater 20:667–681. doi:10.1021/cm702091q

Wang DW, Li F, Liu M, Lu GQ, Cheng HM (2008) 3D aperiodic hierarchical porous graphitic carbon material for high‐rate electrochemical capacitive energy storage. Angew Chem Int Ed 47:373–376. doi:10.1002/anie.200702721

Qiao Y, Zhao X (2009) Electrorheological effect of carbonaceous materials with hierarchical porous structures. Colloids Surf A 340:33–39. doi:10.1016/j.colsurfa.2009.02.036

Rodriguez-Reinoso F, Molina-Sabio M (1992) Activated carbons from lignocellulosic materials by chemical and/or physical activation: an overview. Carbon 30:1111–1118. doi:10.1016/0008-6223(92)90143-K

Hwang YJ, Jeong SK, Nahm KS, Shin JS, Manuel SA (2007) Pyrolytic carbon derived from coffee shells as anode materials for lithium batteries. J Phys Chem Solids 68:182–188. doi:10.1016/j.jpcs.2006.10.007

Fey GTK, Chen CL (2001) High-capacity carbons for lithium-ion batteries prepared from rice husk. J Power Sources 97:47–51. doi:10.1016/S0378-7753(01)00504-3

Zhang F, Wang KX, Li GD, Chen JS (2009) Hierarchical porous carbon derived from rice straw for lithium-ion batteries with high-rate performance. Electrochem Commun 11:130–133. doi:10.1016/j.elecom.2008.10.041

Ryoo R, Joo SH, Jun S (1999) Synthesis of highly ordered carbon molecular sieves via template-mediated structural transformation. J Phys Chem B 103:7743–7746. doi:10.1021/jp991673a

Jun S, Joo SH, Ryoo R, Kruk M, Jaroniec M, Liu Z, Ohsuna T, Terasaki O (2000) Synthesis of new, nanoporous carbon with hexagonally ordered mesostructure. J Am Chem Soc 122:10712–10713. doi:10.1021/ja002261e

Kim MS, Fang BZ, Yang DS, Bae TS, Yu JS (2013) Morphology-dependent Li storage performance of ordered mesoporous carbon as anode material. Langmuir 29:6754–6761. doi:10.1021/la401150t

Hu YS, Adelhelm PL, Smrsly BM, Hore S, Antonietti M, Maier J (2007) Synthesis of hierarchically porous carbon monoliths with highly ordered microstructure and their application in rechargeable lithium batteries with high‐rate capability. Adv Funct Mater 17:1873–1878. doi:10.1002/adfm.200601152

Li Z, Xu ZW, Tan XH, Wang HL, Holt CMB, Stephenson T, Olsen BC, Mitlin D (2013) Mesoporous nitrogen-rich carbons derived from protein for ultra-high capacity battery anodes and supercapacitors. Energy Environ Sci 6:871–878. doi:10.1039/c2ee23599d

Lee J, Sohn K, Hyeon T (2002) Low-cost and facile synthesis of mesocellular carbon foams. Chem Commun 22:2674–2675. doi:10.1039/B208642E

Kim SS, Pinnavaia TJ (2001) A low cost route to hexagonal mesostructured carbon molecular sieves. Chem Commun 23:2418–2419. doi:10.1039/B107896H

Kresge CT, Leonowicz ME, Roth WJ, Vertuli JC, Beck JS (1992) Ordered mesoporous molecular sieves synthesized by a liquid-crystal template mechanism. Nature 359:710–712. doi:10.1038/359710a0

Shio S, Kimura A, Yamaguchi M, Yoshida K, Kuroda K (1998) Morphological control of ordered mesoporous silica: formation of fine and rod-like mesoporous powders from completely dissolved aqueous solutions of sodium metasilicate and cationic surfactants. Chem Commun 22:2461–2462. doi:10.1039/a807424k

Zhao DY, Sun JY, Li QZ, Stucky GD (2000) Morphological control of highly ordered mesoporous silica SBA-15. Chem Mater 12:275–279. doi:10.1021/cm9911363

Beck JS, Vartuli JC, Roth WJ, Leonowicz ME, Kresge CT, Schmidt KD, Chu CTW, Olson DH, Sheppard EW (1992) A new family of mesoporous molecular sieves prepared with liquid crystal templates. J Am Chem Soc 114:10834–10843. doi:10.1021/ja00053a020

Huo Q et al (1994) Generalized synthesis of periodic surfactant/inorganic composite materials. Nature 368:317–321

Tanev PT, Pinnavaia TJ (1996) Mesoporous silica molecular sieves prepared by ionic and neutral surfactant templating: a comparison of physical properties. Chem Mater 8:2068–2079. doi:10.1021/cm950549a

Tanev PT, Pinnavaia TJ (1996) Biomimetic templating of porous lamellar silicas by vesicular surfactant assemblies. Science 271:1267–1269. doi:10.1126/science.271.5253.1267

Stark WJ, Pratsinis SE, Baiker A (2001) Flame made titania/silica epoxidation catalysts. J Catal 203:516–524. doi:10.1006/jcat.2001.3365

Hinklin T, Toury B, Gervais C, Babonneau F, Gislason JJ, Morton RW, Laine RM (2004) Liquid-feed flame spray pyrolysis of metalloorganic and inorganic alumina sources in the production of nanoalumina powders. Chem Mater 16:21–30. doi:10.1021/cm021782t

Laine RM, Marchal J, Sun H, Pan XQ (2005) A new Y3Al5O12 phase produced by liquid‐feed flame spray pyrolysis (LF‐FSP). Adv Mater 17:830–833. doi:10.1002/adma.200401001

Feng X, Sayle DC, Wang ZL et al (2006) Converting ceria polyhedral nanoparticles into single-crystal nanospheres. Science 312:1504–1508. doi:10.1126/science.1125767

Zhao N, Gao MY (2009) Magnetic janus particles prepared by a flame synthetic approach: synthesis, characterizations and properties. Adv Mater 21:184–187. doi:10.1002/adma.200800570

Fukui H, Ohsuka H, Hino T, Kanamura K (2010) A Si-O-C composite anode: high capability and proposed mechanism of lithium storage associated with microstructural characteristics. ACS Appl Mater Interfaces 2:998–1008. doi:10.1021/am 100030f

Zhou X, Guo YG (2014) Highly disordered carbon as a superior anode material for room‐temperature sodium‐ion batteries. ChemElectroChem 1:83–86. doi:10.1002/celc.201300071

Ferrari AC, Robertson CJ (2000) Interpretation of Raman spectra of disordered and amorphous carbon. Phys Rev B 61:14095. doi:10.1103/PhysRevB.61.14095

Pan DY, Wang S, Zhao B, Wu MH, Zhang HJ, Wang Y, Jiao Z (2009) Li storage properties of disordered graphene nanosheets. Chem Mater 2:3136–3142. doi:10.1021/cm900395k

Wu YP, Wan CR, Jiang CY, Fang SB, Jiang YY (1999) Mechanism of lithium storage in low temperature carbon. Carbon 37:1901–1908. doi:10.1016/S0008-6223(99)00067-6

Han XY, Qing GY, Sun JT, Sun TL (2012) How many lithium ions can be inserted onto fused C6 aromatic ring systems? Angew Chem Int Ed 51:5147–5151. doi:10.1002/anie.201109187

Ania CO, Parra JB, Pevida C, Arenillas A, Rubiera F, Pis JJ (2005) Pyrolysis of activated carbons exhausted with organic compounds. J Anal Appl Pyrolysis 74:518–524. doi:10.1016/j.jaap.2004.10.008

Mabuchi A, Tokumitsu K, Fujimoto H, Kasuh T (1995) Charge‐discharge characteristics of the mesocarbon miocrobeads heat‐treated at different temperatures. J Electrochem Soc 142:1041–1046

Kaskhedikar NA, Joachim M (2009) Lithium storage in carbon nanostructures. Adv Mater 21:2664–2680. doi:10.1002/ adma.200901079

Ruike M, Kasu T, Setoyama N et al (1994) Inaccessible pore characterization of less-crystalline microporous solids. J Phys Chem 98:9594–9600. doi:10.1021/j100089a038

Hanzawa Y, Hatori H, Yoshizawa N et al (2002) Structural changes in carbon aerogels with high temperature treatment. Carbon 40:575–581. doi:10.1016/S0008-6223(01)00150-6

Hayashi J, Kazehaya A, Muroyama K et al (2000) Preparation of activated carbon from lignin by chemical activation. Carbon 38:1873–1878. doi:10.1016/S0008-6223(00)00027-0

Yang J, Zhou XY, Zou YL, Tang JJ (2011) A hierarchical porous carbon material for high power lithium-ion batteries. Electrochim Acta 56:8576–8581. doi:10.1016/j.electacta.2011.07.047

Yamada H, Watanabe Y, Moriguchi I, Kudo T (2008) Rate capability of lithium intercalation into nanoporous graphitized carbons. Solid State Ionics 179:1706–1709. doi:10.1016/j.ssi.2008.02.022

Fang BZ, Kim KS, Kim JH, Lim SM, Yu JS (2010) Ordered multimodal porous carbon with hierarchical nanostructure for high Li storage capacity and good cycling performance. J Mater Chem 20:10253–10259. doi:10.1039/c0jm01387k

Li HQ, Liu RL, Zhao DY, Xia YY (2007) Electrochemical properties of an ordered mesoporous carbon prepared by direct tri-constituent co-assembly. Carbon 45:2628–2635. doi:10.1016/j.carbon.2007.08.005

Zhou H, Zhu S, Hibino M, Honma I, Ichihara M (2003) Lithium storage in ordered mesoporous carbon (CMK‐3) with high reversible specific energy capacity and good cycling performance. Adv Mater 15:2107–2011. doi:10.1002/adma.200306125

Yang SB, Huo JP, Song HH, Chen XH (2008) A comparative study of electrochemical properties of two kinds of carbon nanotubes as anode materials for lithium ion batteries. Electrochim Acta 53:2238–2244. doi:10.1016/j.electacta.2007.09.040

Su DS, Schlögl R (2010) Nanostructured carbon and carbon nanocomposites for electrochemical energy storage applications. ChemSusChem 3:136–168. doi:10.1002/cssc.200900182

Ng SH, Wang J, Guo ZP, Chen J, Wang GX, Liu HK (2005) Single wall carbon nanotube paper as anode for lithium-ion battery. Electrochim Acta 51:23–28. doi:10.1016/j.electacta.2005.04.045

Chen Z, Wen J et al (2011) High‐performance supercapacitors based on hierarchically porous graphite particles. Adv Energy Mater 1:551–556. doi:10.1002/aenm.201100114

Yang SB, Feng XL, Zhi LJ, Cao Q, Maier J, Küllen K (2010) Nanographene‐constructed hollow carbon spheres and their favorable electroactivity with respect to lithium storage. Adv Mater 22:838–842. doi:10.1002/adma.200902795

Kim MS, Fang B, Kim JH et al (2011) Ultra-high Li storage capacity achieved by hollow carbon capsules with hierarchical nanoarchitecture. J Mater Chem 21:19362–19367. doi:10.1039/c1jm13753k

Song R, Song HH, Zhou J, Chen X, Wu B, Yang HY (2012) Hierarchical porous carbon nanosheets and their favorable high-rate performance in lithium ion batteries. J Mater Chem 22:12369–12374. doi:10.1039/c2jm31910a

Acknowledgments

We greatly appreciate the Natural Science Foundation of China (21275104, 21177090, and 21175094) for supporting this work.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOC 10638 kb)

Rights and permissions

About this article

Cite this article

Ou, J., Zhang, Y., Chen, L. et al. Hierarchical porous carbons fabricated from silica via flame synthesis as anode materials for high-performance lithium-ion batteries. Ionics 21, 1881–1891 (2015). https://doi.org/10.1007/s11581-014-1348-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-014-1348-0