Abstract

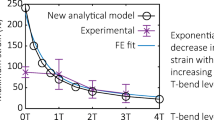

The elastic modulus of a deposit (E d) can be obtained by monitoring the temperature (ΔT) and curvature (Δk) of a one-side coated long plate, namely, a onedimensional (1D) deformation model. The aim of this research is to design an experimental setup that proves whether a 1D deformation model can be scaled for complex geometries. The setup includes a laser displacement sensor mounted on a robotic arm capable of scanning a specimen surface and measuring its deformation. The reproducibility of the results is verified by comparing the present results with Stony Brook University Laboratory’s results. The Δk-ΔT slope error is less than 8%, and the E d estimation error is close to 2%. These values reveal the repeatability of the experiments. Several samples fabricated with aluminum as the substrate and 100MXC nanowire (Fe and Cr alloy) as the deposit are analyzed and compared with those in finite element (FE) simulations. The linear elastic behavior of 1D (flat long plate) and 2D (squared plate) specimens during heating/cooling cycles is demonstrated by the high linearity of all Δk-ΔT curves (over 97%). The E d values are approximately equal for 1D and 2D analyses, with a median of 96 GPa and standard deviation of 2 GPa. The correspondence between the experimental and simulated results for the 1D and 2D specimens reveals that deformation and thermal stress in coated specimens can be predicted regardless of specimen geometry through FE modeling and by using the experimental value of E d. An example of a turbine-bladeshaped substrate is presented to validate the approach.

Similar content being viewed by others

References

Bolelli G, Cannillo V, Lusvarghi L, et al. Functionally graded WC–Co/NiAl HVOF coatings for damage tolerance, wear and corrosion protection. Surface and Coatings Technology, 2012, 206 (8–9): 2585–2601

Matejicek J, Sampath S. In situ measurement of residual stress and elastic moduli in thermal sprayed coatings: Part 1: Apparatus and analysis. Acta Materialia, 2003, 51(3): 863–872

Matejicek J, Sampath S, Gilmore D, et al. In situ measurement of residual stress and elastic moduli in thermal sprayed coatings: Part 2: Processing effects on properties of Mo coatings. Acta Materialia, 2003, 51(3): 873–885

Zhu J, Xie H, Hu Z, et al. Residual stress in thermal spray coatings measured by curvature based on 3D digital image correlation technique. Surface and Coatings Technology, 2011, 206(6): 1396–1402

Georgieva P R, Thorpe A Y, Yanski A, et al. Nanocomposite Materials: An innovative turnover for the wire arc spraying technology. Advanced Materials and Processes, 2006, 164(8): 68

Davis J R. Handbook of Thermal Spray Technology, 2004

Beer F P, Johnston E R. Mechanics of Materials. 7th ed. New York: McGrawHill, 2015

Kanthal A B. Thermostatic bimetal handbook 6th ed, 2008

Budynas R G, Nisbett J K. Shigley’s Mechanical Engineering Design. 8th ed. Mexico D.F.: McGraw-Hill, 2008, 27–240 (in Spanish)

MatWeb. Material properties. 2014, http://www.matweb.com/

Stasa F L, Torby B J. Applied Finite Element Analysis for Engineers. Tokyo: CBS Publishing Japan Ltda, 1986, 185–322

Eischen J W, Chung C, Kim J H. Realistic modeling of edge effect stresses in bimaterial elements. Journal of Electronic Packaging, 1990, 112(1): 16–22

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gaona, D., Valarezo, A. Elastic modulus and thermal stress in coating during heat cycling with different substrate shapes. Front. Mech. Eng. 10, 294–300 (2015). https://doi.org/10.1007/s11465-015-0351-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-015-0351-0