Abstract

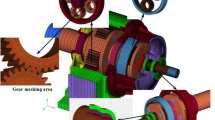

To improve the dynamic performance and reduce the weight of the planet carrier in wind turbine gearbox, a multi-objective optimization method, which is driven by the maximum deformation, the maximum stress and the minimum mass of the studied part, is proposed by combining the response surface method and genetic algorithms in this paper. Firstly, the design points’ distribution for the design variables of the planet carrier is established with the central composite design (CCD) method. Then, based on the computing results of finite element analysis (FEA), the response surface analysis is conducted to find out the proper sets of design variable values. And a multi-objective genetic algorithm (MOGA) is applied to determine the direction of optimization. As well, this method is applied to design and optimize the planet carrier in a 1.5MW wind turbine gearbox, the results of which are validated by an experimental modal test. Compared with the original design, the mass and the stress of the optimized planet carrier are respectively reduced by 9.3% and 40%. Consequently, the cost of planet carrier is greatly reduced and its stability is also improved.

Similar content being viewed by others

References

Rosenberg R S. Simulation of genetic populations with biochemical properties. Dissertation for the Doctoral Degree. Ann Harbor: University of Michigan, 1967

Schaffer J D. Multiple objective optimization with vector evaluated genetic algorithms. In: Proceedings of the 1st International Conference on Genetic Algorithms. Pittsburgh, 1985, 93–100

Rodriguez-Vazquez K, Fonseca C M, Fleming P J. Multiobjective genetic programming: A nonlinear system identification application. In: Proceedings of the Genetic Programming 1997 Conference. California, 1997, 207–212

Fonseca C M, Fleming P J. Nonlinear systems identification with multi-objective genetic algorithms. In: Proceedings of the 13th World Congress of IFAC. San Francisco, 1996, 187–192

Fonseca C M, Fleming P J. An overview of evolutionary algorithms in multiobjective optimization. Evolutionary Computation, 1995, 3(1): 1–16

McInerny S A, Hardman W, Keller J A, et al. Detection of a cracked planet carrier. In: Proceedings of the 10th International Congress on Sound and Vibration. Stockholm, 2003, 4981–4988

Blunt D M, Keller J A. Detection of a fatigue crack in a UH-60A planet gear carrier using vibration analysis. Mechanical Systems and Signal Processing, 2006, 20(8): 2095–2111

Keller J A, Grabill P. Vibration monitoring of UH-60A main transmission planetary carrier fault. In: Proceedings of the 59th American Helicopter Society Annual Forum. Phoenix, 2003, 1233–1243

Eritenel T, Parker R G. Modal properties of three-dimensional helical planetary gears. Journal of Sound and Vibration, 2009, 325(1–2): 397–420

Zhang Z H, Liu Z M, Zhang H P, et al. Structural analysis and optimization on the planet frame of large scaled gearbox of wind turbine. Journal of Machine Design, 2008, 25(9): 54–56 (in Chinese)

Xing Y, Moan T. Multi-body modeling and analysis of a planet carrier in a wind turbine gearbox. Wind Energy (Chichester, England), 2013, 16(7): 1067–1089

Alì G, Butera F, Rotundo N. Geometrical and physical optimization of a photovoltaic cell by means of a genetic algorithm. Journal of Computational Electronics, 2014, 13(1): 323–328

Affi Z, EL-Kribi B, Romdhane L. Advanced mechatronic design using a multi-objective genetic optimization of a motor-driven fourbar system. Mechatronics, 2007, 17: 489–500

Rossetti A, Macor A. Multi-objective optimization of hydromechanical power split transmissions. Mechanism and Machine Theory, 2013, 62: 112–128

Pang X, Rybarcyk L J. Multi-objective particle swarm and genetic algorithm for the optimization of the LANSCE linac operation. Nuclear Instruments & Methods in Physics Research. Section A, Accelerators, Spectrometers, Detectors and Associated Equipment, 2014, 741: 124–129

Sanaye S, Katebi A. 4E analysis and multi objective optimization of a micro gas turbine and solid oxide fuel cell hybrid combined heat and power system. Journal of Power Sources, 2014, 247: 294–306

Velea MN, Wennhage P, Zenkert D. Multi-objective optimization of vehicle bodies made of FRP sandwich structures. Composite Structures, 2014, 111: 75–84

Hao D, Wang D. Finite-element modeling of the failure of interference-fit planet carrier and shaft assembly. Engineering Failure Analysis, 2013, 33: 184–196

Yi P, Dong L, Chen Y. The multi-objective optimization of the planet carrier in wind turbine gearbox. Applied Mechanics and Materials, 2012, 184–185: 565–569

Park C I L. Multi-objective optimization of the tooth surface in helical gears using design of experiment and the response surface method. Journal of Mechanical Science and Technology, 2010, 24(3): 823–829

Yadav P K, Agarwal S, Yadav R K. Optimization of a truss structure using FEA and surface response method. International Journal of Applied Engineering Science, 2014, 9(1): 81–86

Chakraborty S, Sen A. Adaptive response surface based efficient finite element model updating. Finite Elements in Analysis and Design, 2014, 80: 33–40

Carrano E G, Cardoso R T N, Takahashi R H C, et al. Power distribution network expansion scheduling using dynamic programming genetic algorithm. IET Generation, Transmission & Distribution, 2008, 2(3): 444–455

Park E, Lee Y J. Estimation of standard deviation of Spearman rank correlation coefficients with dependent observations. Communications in Statistics Simulation and Computation, 2001, 30(1): 129–142

Rajmohan T, Palanikumar K. Application of the central composite design in optimization of machining parameters in drilling hybrid metal matrix composites. Measurement, 2013, 46(4): 1470–1481

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yi, P., Dong, L. & Shi, T. Multi-objective genetic algorithms based structural optimization and experimental investigation of the planet carrier in wind turbine gearbox. Front. Mech. Eng. 9, 354–367 (2014). https://doi.org/10.1007/s11465-014-0319-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-014-0319-5