Abstract

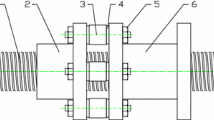

A revolving electromagnetic actuation mechanism composed of an electromagnetic stator and an electromagnetic rotor has been developed for boring non-circular holes. The main component of the rotor is a flexure-hinged based flexible body. There are four pole-pair coils in the stator supplying actuation currents. The micro-displacement between the stator and rotor can be controlled by changing the currents applied in the pole-pair coils. Through linearization of the actuation force near the static action point, a linear relationship between the control current and the actuation force was established, and the synchronizing control method of the electromagnetic actuation mechanism is presented here. With two-factor analysis of the linearization error of the actuation force, the influences of control current and micro-displacement to the linearization error of the actuation force were studied. Then, the principle for designing the basic parameters of the magnetic actuation mechanism is put forward. The calibration of the mechanism indicates that the relationship between the micro-displacement of the rotor and the control current has linear characteristics in the required micro-displacement range. Simulation tests show that the turning radius of the rotor changes with the control current. The proposed mechanism can feasibly supply a controllable micro displacement to the boring bar.

Similar content being viewed by others

References

Zhou Huixing, Zhang Linna, Wang Xiankui, Jinling Liu, Repetitive control and application to linear servo unit for CNC machining of elliptical pistons, Proceedings of the IEEE International Conference on Industrial Technology, Shanghai, 1996, 630–633

Alter David M, Tsao Tsu-Chin, Implementation of a direct drive linear motor actuator for dynamic control of the turning process, American Control Conference, California, 1993, 1 971–1 975

Zhu Wenhong, Martin B J, Yusuf Altintas, A fast tool design for precision turning of shafts on conventional CNC lathes, Int J Mach Tools & Manufact, 2001, 41:953–965

Jeong-Du Kim, Soo-Ryong Nam, Development of a micro-depth control system for an ultra-precision lathe using a piezo-electric actuator, International Journal of Machine Tools and Manufacture, 1997, 37(4): 495–509

Seung-Bae Jung, Seung-Woo Kim, Improvement of scanning accuracy of PZT piezoelectric actuators by feed-forward model-reference control, Precision Engineering, 1994, 16(1): 49–55

Tsao Tsu-Chin, Tomizuka Masayoshi, Robust adaptive and repetitive digital tracking control and application to a hydraulic servo for noncircular machining, Journal of Dynamic Systems, Measurement and Control, Transaction of the ASME, 1994, 116(3): 24–32

Sugita Kazuhiko, Yamakawa Yoichi, Sakaibara Norio, Development of a noncircular high speed generating mechanism by hybrid system with VCM and PZT, Journal of the Japan Society for Precision Engineering, 1992, 58(9): 1 503–1 508

Rohit G Reddy, Richard E DeVor, Shiv G Kapoor, et al, A mechanistic model-based force-feedback scheme for voice-coil actuated radial contour turning, International Journal of Machine Tools and Manufacture, 2001, 41(8): 1 131–1 147

Wilfied Sander und Walter Kelm, Formgedrehte bohrungen zur bolzenlagerung hochbelasteter kolben, MTZ Motortechnische eitschrift, 1981, 42(10): 409–412

Xu Jingyong, Wong Shaoyu, Machining principle and equipment for boring of non-circular hole of piston, Shanghai Machine Tool, 1998, (1): 22–24

Liu Bingyun, Boring apparatus for noncircular piston bin hole, Patent of Invention, Patent Document Press, Beijing, 1999

Binzhou Piston Factory, Boring machining tool for noncircular hole, Patent of INvention, Beijing: Patent Document Press, 1992

Muller B, Using high-speed electrospindle with active magnetic bearing for boring of noncircular shape, Proc of the 2nd Int Symp on Magnetic Bearings, Tokyo, July 1990, 189–196

Lou Xiangming, Research on the on-line identification of rotor unbalance, Hangzhou: Zhejiang University, 2001

Author information

Authors and Affiliations

Corresponding author

Additional information

__________

Translated from Journal of Shanghai Jiaotong University, 2005, 39(6) (in Chinese)

Rights and permissions

About this article

Cite this article

Zhang, K., Hu, Dj. A new method for boring of non-circular holes. Front. Mech. Eng. China 1, 456–460 (2006). https://doi.org/10.1007/s11465-006-0058-3

Issue Date:

DOI: https://doi.org/10.1007/s11465-006-0058-3