Abstract

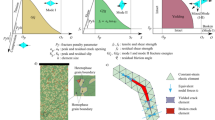

Built on the framework of effective interaction potentials using lattice element method, a methodology to calibrate and to validate the elasticity of solid constituents in heterogeneous porous media from experimentally measured nanoindentation moduli and imported scans from advanced imaging techniques is presented. Applied to computed tomography (CT) scans of two organic-rich shales, spatial variations of effective interaction potentials prove instrumental in capturing the effective elastic behavior of highly heterogeneous materials via the first two cumulants of experimentally measured distributions of nanoindentation moduli. After calibration and validation steps while implicitly accounting for mesoscale texture effects via CT scans, Biot poroelastic coefficients are simulated. Analysis of stress percolation suggests contrasting pathways for load transmission, a reflection of microtextural differences in the studied cases. This methodology to calibrate elastic energy content of real materials from advanced imaging techniques and experimental measurements paves the way to study other phenomena such as wave propagation and fracture while providing a platform to fine-tune effective behavior of materials given advancements in additive manufacturing and machine learning algorithms .

Similar content being viewed by others

References

Abedi S, Slim M, Hofmann R, Bryndzia T, Ulm FJ (2016) Nanochemo-mechanical signature of organic-rich shales: a coupled indentation-EDX analysis. Acta Geotech 11:559–572

Abousleiman Y, Hull K, Han Y, Al-Muntasheri G, Hosemann P, Parker S, Howard C (2016) The granular and polymer composite nature of kerogen-rich shale. Acta Geotech 11(3):573–594

Affes R, Delenne JY, Monerie R, Radjai F, Topin V (2012) Tensile strength and fracture of cemented granular aggregates. Eur Phys J E Soft Matter 35:117

Aleksandrov K, Ryzhova T (1961) Elastic properties of rock-forming minerals. II. Layered silicates. Bull USSR Acad Sci Geophys Ser 9:1165

Bathe KJ (2014) Finite element procedure. Prentice Hall, Upper Saddle River

Beneviste Y (1987) A new approach to the application of Mori–Tanaka’s theory in composite materials. Mech Mater 6(2):147

Beran M (1968) Statistical continuum theories. Wiley, London

Beroz F, Jawerth L, Munster S, Weitz D, Broedersz C (2017) Physical limits to biomechanical sensing in disordered fibre network. Nat Commun 8:16096

Berryman J (2005) Bounds and self-consistent estimates for elastic constants of random polycrystals with hexagonal, trigonal, and tetragonal symmetries. J Mech Phys Solids 53(10):2141

Berthonneau J, Grauby O, Abuhaikal M, Pellenq RJM, Ulm FJ, Van Damme H (2016) Evolution of organo-clay composites with respect to thermal maturity in type II organic-rich source rocks. Geochim Cosmochim Acta 195:68–83

Biot M (1941) General theory of three-dimensional consolidation. J Appl Phys 12(2):155

Bousige C, Ghimbeu C, Vix-Guterl C, Pomerantz A, Suleimenova A, Vaughan G, Garbarino G, Feygenson M, Wildgruber C, Ulm FJ, Pellenq RJ, Coasne B (2016) Realistic molecular model of kerogen’s nanostructure. Nat Mater 15:576–582

Budiansky B (1965) On the elastic moduli for some heterogeneous materials. J Mech Phys Solids 13:223

Christoffersen J, Mehrabadi M, Nemat-Nasser S (1984) A micro-mechanical description of granular material behavior. J Appl Mech 48(2):339–344

Constantinidies G, Ravi Chandran K, Ulm FJ, Van Vilet K (2006) Grid indentation analysis of composite microstructure and mechanics: principles and validation. Mater Sci Eng A 430(1–2):189–202

Deirieh A, Ortega J, Ulm FJ (2012) Nanochemomechanical assessment of shale: a coupled WDS-indentation analysis. Acta Geotech 7(4):271–295

Delafargue A, Ulm FJ (2004) Explicit approximations of the indentation modulus of elastically orthotropic solids for conical indenters. Int J Solids Struct 41:7351

Dimas L, Giesa T, Buehler M (2014) Coupled continuum and discrete analysis of random heterogeneous materials: elasticity and fracture. J Mech Phys Solids 63:481–490

Dormieux L, Kondo D, Ulm FJ (2006) Microporomechanics. Wiley, Chichester

Dormieux L, Molinary A, Kondo D (2002) Micromechanical approach to the behavior of poroelastic materials. J Mech Phys Solids 50:571

Ebrahimi D, Whittle A, Pellenq RJM (2014) Mesoscale properties of clay aggregates from potential of mean force representation of interactions between nanoplatelets. J Chem Phys 140:154309

Eshelby J (1957) The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc R Soc A 241:376

Gnedenko B, Kolmogorov A (1954) Limit distributions for sums of independent random variables. Addison-Wesley, Boston

Hantal G, Brochard L, Laubie H, Ebrahimi D, Pellenq JM, Ulm FJ, Cosane B (2014) Atomic-scale modeling of elastic and failure properties of clays. Mol Phys Int J Interface Chem Phys 112:1294

Herrmann H, Roux S (1990) Statistical models for the fracture of disordered media. Random materials and processes. Elsevier, New York

Hershey A (1954) The elasticity of an isotropic aggregate of anisotropic cubic crystal. J Appl Mech 21:226–240

Hill R (1965) A self-consistent mechanics of composite materials. J Mech Phys Solids 13(4):213–222

Hubler M, Gelb J, Ulm FJ (2017) Microtexture analysis of gas shale by XRM imaging. J Nanomech Micromech 7(3):564

Johnson S (2009) The NLOPT nonlinear-optimization package. http://ab-initio.mit.edu/nlopt/

Kardar M (2007) Statistical physics of particles. Cambridge University Press, Cambridge

Katahara K (1996) Clay minerals elastic properties. In: Proceedings of the 66th SEG annual meeting expanded technical program abstracts

Kröner E (1958) Berechnung der elastischen Konstanten des Vielkristalls aus den Konstanten des Einkristalls. Z Phys 151(4):504–518

Larsson P, Giannakopoulos A, SoDerlund E, Rowcliffe D, Vetergaard R (1996) Analysis of Berkovich indentation. Int J Solids Struct 33:221

Laubie H, Monfared S, Radjai F, Pellenq RM, Ulm FJ (2017) Disorder-induced stiffness degradation of highly disordered porous materials. J Mech Phys Solids 106:207–228

Laubie H, Monfared S, Radjai F, Pellenq RM, Ulm FJ (2017) Effective potentials and elastic properties in the lattice-element method: isotropy and transverse isotropy. J Nanomech Micromech 7:3

Laubie H, Radjai F, Pellenq R, Ulm FJ (2017) Stress transmission and failure in disordered porous media. Phys Rev Lett 119:075501

Masoero E, Del Gado E, Pellenq RM, Ulm FJ, Yip S (2012) Nanostructure and nanomechanics of cement: polydisperse colloidal packing. Phys Rev Lett 109:3–6

Masoero E, Del Gado E, Pellenq RM, Ulm FJ, Yip S (2014) Nano-scale mechanics of colloidal C-S-H gels. Soft Matter 10:491

Mavko G, Mukerji T, Dvorkin J (2003) Rock physics handbook: tools for seismic analysis in porous media. Cambridge University Press, Cambridge

Monfared S, Laubie H, Radjai F, Pellenq RM, Ulm FJ (2017) Mesoscale poroelasticity of heterogeneous media. J Nanomech Micromech 7(4):04017016

Monfared S, Ulm FJ (2016) A molecular informed poroelastic model for organic-rich, naturally occurring porous geocomposites. J Mech Phys Solids 88:186

Mori T, Tanaka K (1973) Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall 21:571

Norris A (2014) Mechanics of elastic networks. Proc R Soc A 470:20140522

Powell M (1994) A direct search optimization method that models the objective and constraint functions by linear interpolation. In: Gomez S, Hennart J-P (eds) Advances in optimization and numerical analysis. Kluwer Academic, Dordrecht

Powell M (1998) Direct search algorithms for optimization calculations. Acta Numer 7:287

Radjai F, Jean M, Moreau JJ, Roux S (1996) Force distribution in dense two-dimensional granular systems. Phys Rev Lett 77:274

Seewald J (2003) Organic-inorganic interactions in petroleum-producing sedimentary basins. Nature 426:327–333

Semnani SJ, Borja RI (2017) Quantifying the heterogeneity of shale through statistical combination of imaging across scales. Acta Geotech 12:1193–1205

Seo YS, Ichikawa Y, Kawamura K (1999) Stress-strain response of rock forming minerals by MD simulations. Mater Sci Res Int 5:13

Silling S, Lehoucq R (2010) Peridynamic theory of solid mechanics, pp. 87185–1322 . Tech. Rep. 1, Sandia National Laboratories, Albuquerque, New Mexico, USA

Suquet M (1987) Elements of homogenization for inelastic solid mechanics. In: Homogenization techniques for composite media. Springer, Berlin, pp 193–278

Tai K, Dao M, Suresh S, Palazoglu A, Ortiz C (2007) Nanoscale heterogeneity promotes energy dissipation in bone. Nat Mater 6:454

Tissot B, Welte D (1984) Petroleum formation and occurrence. Springer, Berlin

Topin V, Delenne JY, Radjai F, Brendel L, Mabille F (2007) Strength and failure of cemented granular matter. Eur Phys J E Soft Matter 23:413

Torquato S (2002) Random heterogeneous materials: microstructure and macroscopic properties. Springer, Berlin

Ulm FJ, Vandamme M, Bobko C, Ortega J, Tai K, Ortiz C (2007) Statistical indentation techniques for hydrated nanocomposites: concrete, bone, and shale. J Am Chem Soc 90(9):2677–2692

Vaughan M, Guggenheim S (1986) Elasticity of muscovite and its relationship to crystal structure. J Geophys Res 91:4657

Veneziano D (2003) Computational fluid and solid mechanics. Elsevier, Cambridge

Weibull W (1939) A statistical theory of the strength of materials. R Swed Inst Eng Res (Ingenors Vetenskaps Akadiens Handlingar) 151:1

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18:293–297

Younis S, Kauffmann Y, Bloch L, Zolotoyabko E (2012) Inhomogeneity of nacre lamellae on the nanometer length scale. Cryst Growth Des 12(9):4574–4579

Zaoui A (2002) Continuum micromechanics: a survey. J Eng Mech 8:808

Acknowledgements

This work was funded by X-Shale Hub: the Science and Engineering of Gas Shale, a collaboration between Shell, Schlumberger, and the Massachusetts Institute of Technology, enabled through MIT’s Energy Initiative. Authors would like to acknowledge Vincent Richefeu (Universite Joseph Fourier), Jean-Yves Delenne (Montpellier SupAgro) and Saeid Nezamabadi (Universite de Montpellier) who provided the backbone of the LEM code used for simulations. FR would like to acknowledge the support of the ICoME2 Labex (ANR-11-LABX-0053) and the A\(*\)MIDEX projects (ANR-11-IDEX-0001-02) cofunded by the French program Investissements d Avenir, managed by the French National Reseach Agency (ANR).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Monfared, S., Laubie, H., Radjai, F. et al. A methodology to calibrate and to validate effective solid potentials of heterogeneous porous media from computed tomography scans and laboratory-measured nanoindentation data. Acta Geotech. 13, 1369–1394 (2018). https://doi.org/10.1007/s11440-018-0687-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-018-0687-9