Abstract

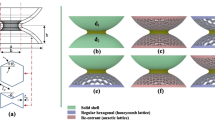

A new type of ultra-lightweight metallic lattice structure (named as the X-type structure) is reported. This periodic structure was formed by two groups of staggered struts in the traditional pyramid structure, and fabricated by folding expanded metal sheet along rows of offset nodes and then brazing the folded structure (as the core) with top and bottom facesheets to form sandwich panels. The out-of-plane compressive and shear properties of the X-type lattice sandwich structure were investigated experimentally and compared to those of the sandwich having a pyramidal truss core. It is found that the formation of the 2-dimensional staggered nodes can effectively make the X-type structure more resistant to inelastic and plastic buckling under both compression and shear loading than the pyramidal lattice truss. Obtained results show that the compressive and shear peak strengths of the X-type lattice structure are about 30% higher than those of the pyramidal lattice truss having the same relative density.

Similar content being viewed by others

References

Evans A G, Hutchinson J W, Fleck N A, et al. The topological design of multifunctional cellular metals. Prog Mater Sci, 2001, 46(3–4): 309–327

Lu T J, He D P, Chen C, et al. The multi-functionality of multi- functionality of ultra-light porous metals and their applications (in Chinese). Adv Mech, 2006, 36(4): 517–535

Fan H L, Yang W. Development of lattice materials with high specific stiffness and strength (in Chinese). Adv Mech, 2007, 37(1): 99–112

Wadley H N G. Multifunctional periodic cellular metals. Phil Trans R Soc A, 2006, 364(1838): 31–68

Lu T J, Zhang Q C, Wang C Y, et al. Application of lightweight materials and structures in machine tools (in Chinese). Mech Eng, 2007, 29(6): 1–9

Lu T J, Liu T, Deng Z C. Multifunctional design of cellular metals: A review (in Chinese). Mech Eng, 2008, 30(1): 1–9

Lu T J, Liu T, Deng Z C. Thermoelastic properties of pin-reinforced sandwich foam cores. Sci China Ser E-Tech Sci, 2008, 51(2): 1–16

Fan H L, Yang W, Fang D N, et al. Interlacing technique for new carbon fiber lattice materials (in Chinese). J Aeronaut Mater, 2007, 27(01): 73–77

Zhang D L, Chen Z M, Xu M L, et al. Feasibility of ECT technique in NDT of ultralight lattice material of sandwich structure. Nondestr Test, 2008, 30(7): 704–711

Ashby M F, Evans A G, Fleck N A, et al. Metal Forms: A Design Guide. Boston: Butterworth-Heinemann, 2000

Lu T J, Hutchinson J W, Evans A G. Optimal design of a flexural actuator. J Mech Phys Solids, 2001, 49(9): 2071–2093

Gu S, Lu T J, Evans A G. On the design of two-dimensional cellular metals for combined heat dissipation and structural load capacity. Int J Heat Mass Transf, 2001, 44(11): 2163–2175

Wallach J C, Gibson L J. Mechanical behavior of a three-dimensional truss material. Int J Solid Struct, 2001, 38(40–41): 7181–7196

Sypeck D J, Wadley H N G. Cellular Metals and Metal Foaming Technology. Bremen: MIT-Verlag, 2001

Sypeck D J, Wadley H N G. Cellular metal truss core sandwich structures. Adv Eng Mater, 2002, 4(10): 759–764

Chiras S, Mumm D R, Evans A G, et al. The structural performance of near-optimized truss core panels. Int J Solid Struct, 2002, 39(15): 4093–4115

Sugimura Y. Mechanical response of single-layer tetrahedral trusses under shear loading. Mech Mater, 2004, 36(8): 715–721

Wicks N, Hutchinson J W. Performance of sandwich plates with truss cores. Mech Mater, 2004, 36(8): 739–751

Wallach J C, Gibson L J. Defect sensitivity of a 3D truss material. Scripta Mater, 2001, 45(6): 639–644

Deshpande V S, Fleck N A, Ashby M F. Effective properties of the octet-truss lattice material. J Mech Phys Solid, 2001, 49(8): 1747–1769

Zhou J, Shrotriya P, Soboyejo W O. On the deformation of aluminum lattice block structures: From struts to structures. Mech Mater, 2004, 36(8): 723–737

Hyun S, Torquato S. Qptimal and manufacturable two-dimensional Kagome-like cellular solids. J Mater Res, 2002, 17(1): 137–144

Lee Y H, Lee B K, Jeon I, et al. Wire-woven bulk Kagome truss cores. Acta Mater, 2007, 55(18): 6084–6094

Sypeck D J, Wadley H N G. Multifunctional microtruss laminates: Textile synthesis and properties. J Mater Res, 2001, 16(3): 890–897

Zok F W, Rathbun H J, Wei Z, et al. Design of metallic textile core sandwich panels. Int J Solid Struct, 2003, 40(21): 5707–5722

Chiras S, Mumm D R, Evans A G, et al. The structural performance of near-optimized truss core panels. Int J Solid Struct, 2002, 39(15): 4093–4115

Zupan M, Deshpande V S, Fleck N A. The out-of-plane compressive behavior of woven-core sandwich plates. Euro J Mech A/Solids, 2004, 23(2): 411–421

Deshpande V S, Ashby M F, Fleck N A. Foam topology bending versus stretching dominated architectures. Acta Mater, 2001, 49(6): 1035–1040

Kooistra G W, Deshpande V S, Wadley H N G. Compressive behavior of age hardenable tetrahedral lattice truss structures made from aluminium. Acta Mater, 2004, 52(14): 4229–4237

Côté F, Fleck N A, Deshpande V S. Fatigue performance of sandwich beams with a pyramidal core. Int J Fatigue, 2007, 29(8): 1402–1412

Queheillalt D T, Wadley H N G. Cellular metal lattices with hollow trusses. Acta Mater, 2005, 53(2): 303–313

Kooistra G W, Wadley H N G. Lattice truss structures from expanded metal sheet. J Mater Design, 2007, 28(2): 507–514

Hyun S, Karlsson A M, Torquato S, et al. Simulated properties of Kagome and tetragonal truss core panel. Int J Solid Struct, 2003, 40(25): 6989–6998

Wang J, Evans A G, Dharmasena K, et al. On the performance of truss panels with Kagome cores. Int J Solid Struct, 2003, 40(25): 6981–6988

Lim J H, Kang K J, Lim J H, et al. Mechanical behavior of sandwich panels with tetrahedral and Kagome truss cores fabricated from wires. Int J Solid Struct, 2006, 43(17): 5228–5246

Zhang Y H, Qiu X M, Fang D N. Mechanical properties of two novel planar lattice structures. Int J Solid Struct, 2008, 45(13): 3751–3768

Zhang Q C, Chen A P, Chen C, et al. Ultralight X-type lattice sandwich structure (II): Micromechanics modeling and finite element analysis. Sci China Ser E-Tech Sci, 2009, doi: 10.1007/s11431-009-0228-8

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Basic Research Program of China (“973” Project) (Grant No. 2006CB601202), the National Natural Science Foundation of China (Grant Nos. 10632060,10825210), the National “111” Project of China (Grant No. B06024) and the National High-Tech Research and Development Program of China (“863” Project) (Grant No. 2006AA03Z519)

Rights and permissions

About this article

Cite this article

Zhang, Q., Han, Y., Chen, C. et al. Ultralight X-type lattice sandwich structure (I): Concept, fabrication and experimental characterization. Sci. China Ser. E-Technol. Sci. 52, 2147–2154 (2009). https://doi.org/10.1007/s11431-009-0219-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-009-0219-9