Abstract

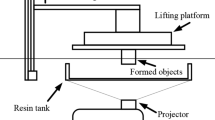

Light-weight and high-strength materials have attracted considerable attention owing to their outstanding properties, such as weight-reducing, acoustic absorption, thermal insulation, shock and vibration damping. Diamond possesses specific stiffness and strength arising from its special crystal structure. In this work, inspired by the diamond crystal structure, hollow-tube nickel materials with the diamond structure were fabricated using a diamond structured polymer template based on the Stereo Lithography Appearance technology. The diamond structured template was coated with Ni-P by electroless plating. Finally, the template was removed by high temperature calcinations. The density of the hollow tube nickel materials is about 20 mg/cm3. The morphology and composition of the resultant materials were characterized by scanning electron microscope, energy-dispersive spectrometry, and X-ray diffraction. The results showed that the surface of the Ni film was uniform with the thickness of 4 μm. The mechanical property was also measured by stress and strain tester. The maximum compression stress can be reached to 40.6 KPa.

Similar content being viewed by others

References

Evans AG, Hutchinson JW, Fleck NA, Ashby MF, Wadley HNG. Prog Mater Sci, 2001, 46: 309–327

Liu Z. Science, 2000, 289: 1734–1736

Kim T, Zhao CY, Lu TJ, Hodson HP. Mech Mater, 2004, 36: 767–780

Barrett DJ. Vibration-damping structural member US Patent: 5087491, 1992

Jeker R, Reiser R. Vibration-damping mount US Patent: 5238215, 1993

Maloney KJ, Roper CS, Jacobsen AJ, Carter WB, Valdevit L, Schaedler TA. APL Mater, 2013, 1: 022106

Jang WY, Kyriakides S, Kraynik AM. Int J Solids Struct, 2010, 47: 2872–2883

Takahashi Y, Okumura D, Ohno N. Int J Mechl Sci, 2010, 52: 377–385

Ahn SH, Lee HJ, Kim GH. Biomacromolecules, 2011, 12: 4256–4263

Lu T, Valdevit L, Evans A. Prog Mater Sci, 2005, 50: 789–815

Maloney KJ, Fink KD, Schaedler TA, Kolodziejska JA, Jacobsen AJ, Roper CS. Int J Heat Mass Transfer, 2012, 55: 2486–2493

Brandner JJ, Anurjew E, Bohn L, Hansjosten E, Henning T, Schygulla U, Wenka A, Schubert K. Exp Thermal Fluid Sci, 2006, 30: 801–809

Ryan TM, Shaw CN. Proc R Soc B-Biol Sci, 2013, 280: 20130172–20130172

Moreau LM, Ha DH, Bealing CR, Zhang H, Hennig RG, Robinson RD. Nano Lett, 2012, 12: 4530–4539

Zheng X, Lee H, Weisgraber TH, Shusteff M, De Otte J, Duoss EB, Kuntz JD, Biener MM, Ge Q, Jackson JA, Kucheyev SO, Fang NX, Spadaccini CM. Science, 2014, 344: 1373–1377

Verdooren A, Chan HM, Grenestedt JL, Harmer MP, Caram HS. J Am Ceramic Soc, 2006, 89: 3101–3106

Tappan BC, Huynh MH, Hiskey MA, Chavez DE, Luther EP, Mang JT, Son SF. J Am Chem Soc, 2006, 128: 6589–6594

Deshpande VS, Fleck NA, Ashby MF. J Mech Phys Solids, 2001, 49: 1747–1769

Zou J, Liu J, Karakoti AS, Kumar A, Joung D, Li Q, Khondaker SI, Seal S, Zhai L. ACS Nano, 2010, 4: 7293–7302

Hu H, Zhao Z, Wan W, Gogotsi Y, Qiu J. Adv Mater, 2013, 25: 2219–2223

Tillotson TM, Hrubesh LW. J Non-Crystline Solids, 1992, 145: 44–50

Schaedler TA, Jacobsen AJ, Torrents A, Sorensen AE, Lian J, Greer JR, Valdevit L, Carter WB. Science, 2011, 334: 962–965

Mecklenburg M, Schuchardt A, Mishra YK, Kaps S, Adelung R, Lotnyk A, Kienle L, Schulte K. Adv Mater, 2012, 24: 3486–3490

Xiong J, Mines R, Ghosh R, Vaziri A, Ma L, Ohrndorf A, Christ HJ, Wu L. Adv Eng Mater, 2015, 17: 1253–1264

Zhu C, Han TYJ, Duoss EB, Golobic AM, Kuntz JD, Spadaccini CM, Worsley MA. Nat Commun, 2015, 6: 6962

do Rosário JJ, Lilleodden ET, Waleczek M, Kubrin R, Petrov AY, Dyachenko PN, Sabisch JEC, Nielsch K, Huber N, Eich M, Schneider GA. Adv Eng Mater, 2015, 17: 1420–1424

Meza LR, Das S, Greer JR. Science, 2014, 345: 1322–1326

Symons DD, Fleck NA. J Appl Mech, 2008, 75: 051011

Deshpande VS, Ashby MF, Fleck NA. Acta Mater, 2001, 49: 1035–1040

Alkhader M, Vural M. Int J Eng Sci, 2008, 46: 1035–1051

Romijn NER, Fleck NA. J Mech Phys Solids, 2007, 55: 2538–2564

Oliver WC, Pharr GM. J Mater Res, 1992, 7: 1564–1583

Li H, Vlassak JJ. J Mater Res, 2009, 24: 1114–1126

Schaedler TA, Jacobsen AJ, Carter WB. Science, 2013, 341: 1181–1182

Geissler M, Xia Y. Adv Mater, 2004, 16: 1249–1269

Sun C, Fang N, Wu DM, Zhang X. Sensors Actuators A-Phys, 2005, 121: 113–120

Zheng X, Deotte J, Alonso MP, Farquar GR, Weisgraber TH, Gemberling S, Lee H, Fang N, Spadaccini CM. Rev Sci Instrum, 2012, 83: 125001–125001

Kitson PJ, Rosnes MH, Sans V, Dragone V, Cronin L. Lab Chip, 2012, 12: 3267–3271

Sun K, Wei TS, Ahn BY, Seo JY, Dillon SJ, Lewis JA. Adv Mater, 2013, 25: 4539–4543

Joe Lopes A, MacDonald E, Wicker RB. Rapid Prototyping J, 2012, 18: 129–143

Woesz A, Rumpler M, Stampfl J, Varga F, Fratzl-Zelman N, Roschger P, Klaushofer K, Fratzl P. Mater Sci Eng-C, 2005, 25: 181–186

Stampfl J, Liska R. Macromol Chem Phys, 2005, 206: 1253–1256

Fu Y, Zhang L, Zheng J. SCI CHINA SER B, 2006, 49: 238–245

Jacobsen AJ, Barvosa-Carter W, Nutt S. Adv Mater, 2007, 19: 3892–3896

Deshpande VS, Ashby MF, Fleck NA. Acta Mater, 2001, 49: 1035–1040

Ashby MF. Philos Trans R Soc A-Math Phys Eng Sci, 2006, 364: 15–30

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, J., Gao, Y., Huang, H. et al. Diamond-structured hollow-tube lattice Ni materials via 3D printing. Sci. China Chem. 59, 1632–1637 (2016). https://doi.org/10.1007/s11426-016-0093-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11426-016-0093-x