Abstract

Purpose

Liquefied natural gas (LNG) is expected to become an important component of the UK’s energy supply because the national hydrocarbon reserves on the continental shelf have started diminishing. However, use of any carbon-based fuel runs counter to mitigation of greenhouse gas emissions (GHGs). Hence, a broad environmental assessment to analyse the import of LNG to the UK is required.

Methods

A cradle to gate life cycle assessment has been carried out of a specific but representative case: LNG imported to the UK from Qatar. The analysis covers the supply chain, from gas extraction through to distribution to the end-user, assuming state-of-the-art facilities and ships. A sensitivity analysis was also conducted on key parameters including the energy requirements of the liquefaction and vaporisation processes, fuel for propulsion, shipping distance, tanker volume and composition of raw gas.

Results and discussion

All environmental indicators of the CML methodology were analysed. The processes of liquefaction, LNG transport and evaporation determine more than 50% of the cradle to gate global warming potential (GWP). When 1% of the total gas delivered is vented as methane emissions leakage throughout the supply chain, the GWP increases by 15% compared to the GWP of the base scenario. The variation of the GWP increases to 78% compared to the base scenario when 5% of the delivered gas is considered to be lost as vented emissions. For all the scenarios analysed, more than 75% of the total acidification potential (AP) is due to the sweetening of the natural gas before liquefaction. Direct emissions from transport always determine between 25 and 49% of the total eutrophication potential (EP) whereas the operation and maintenance of the sending ports strongly influences the fresh water aquatic ecotoxicity potential (FAETP).

Conclusions

The study highlights long-distance transport of LNG and natural gas processing, including sweetening, liquefaction and vaporisation, as the key operations that strongly affect the life cycle impacts. Those cannot be considered negligible when the environmental burdens of the LNG supply chain are considered. Furthermore, the effect of possible fugitive methane emissions along the supply chain are critical for the impact of operations such as extraction, liquefaction, storage before transport, transport itself and evaporation.

Similar content being viewed by others

1 Introduction

With natural gas growing as a component of the global energy economy, trade in natural gas is developing over larger distances than are typically covered by fixed pipelines. Gas is therefore increasingly transported and traded in the form of liquefied natural gas (LNG). Natural gas can be liquefied, stored and transported at a temperature of −161 °C and at atmospheric pressure. The volume of LNG is less than 0.2% of the gas volume so that it can be more easily shipped or stored for use during high demand periods (Bosma and Nagelvoort 2009). Use of LNG is expected to grow, to the point where it could overtake the supply of natural gas through pipes (Kumar et al. 2011). The growing trade in LNG is leading also to additional uses, for example as a land and marine transport fuel (Anderson et al. 2015).

The first shipment of LNG using a purpose-built tanker was delivered to the UK from Algeria in 1964, with a few shipments in ensuing years. However, in 1965, the natural gas reserves in the North Sea were discovered, delaying the further development of LNG infrastructure in the UK (Morris and Messenger 2010). More than 40 years on, production of natural gas on the UK Continental Shelf of the North Sea is declining; attention has therefore returned to import facilities and infrastructure, such as development of Europe’s largest LNG receiving terminal at South Hook in South West Wales (DECC 2014; National Grid 2014). Imported LNG is projected to provide up to 43% of total gas use in the UK by 2035 (National Grid 2014). The UK still depends strongly on gas piped from the North Sea, but LNG imports are increasing from Norway, Belgium, the Netherlands and, in particular, Qatar, thanks to the Qatargas II project, agreed in 2009 with Qatar’s national gas company, Qatargas. This project included the development of 30 offshore wells and three new platforms in Qatar’s North Field. A total of 45 new LNG tankers have been built for the new projects developed by Qatargas, including the Q-flex and Q-max types (Qatargas 2014). In 2013, Centrica, the owner of British gas, signed a contract with Qatargas to import 3 million tonnes of LNG, which will provide 13% of the UK gas demand from now until 2018 (Harvey 2013). Other countries increasing their LNG imports from Qatar also include Japan, South Korea, Portugal, Italy and Taiwan.

Because the quantity of carbon dioxide emitted per unit of combustion energy is lower than for any other carbon-based fuel, LNG has been promoted as a ‘clean fuel’ (Kumar et al. 2011). This gives it a particular status in development plans; for example, LNG is advocated as one of the pillars of development of a ‘clean energy’ industry in British Columbia (Moorhouse et al. 2015), whilst in Europe LNG is considered as an alternative fuel key to improving the security of energy supply, reducing the impact of transport on the environment and boosting EU competitiveness (European Commission 2014). This paper adds to the growing body of work on LNG investigating the life cycle environmental impacts of extracting, processing, transporting and delivering natural gas as LNG. It examines a specific supply chain, from Qatar in the Persian Gulf to the UK, because this is seen as one of the largest future trade routes and is broadly representative of the anticipated future trade in LNG.

1.1 The LNG supply chain

Liquefied natural gas is natural gas that has been converted into liquid after being pre-processed to eliminate impurities, such as water, associated liquids and acid molecules. The heavier liquids and condensate are extracted to be sold separately or used as refrigerant later in the cooling process. If present, nitrogen and helium are also removed. CO2 and H2S are chemically or physically absorbed in solvents and removed to avoid frozen deposits that could cause clogging in the downstream liquefaction equipment. The purified gas is finally dried before liquefaction in chillers. Different liquefaction technologies are described in literature (Bosma and Nagelvoort 2009). LNG is stored and loaded into purpose designed tankers.

The vapours created due to the ambient heat input, whilst maintaining constant pressure in the storage vessel, are called “boil-off” (Ursan 2011) and depend on many factors including weather, sea states, shipboard operations, ambient temperature, etc. The boil-off rate is reported to range between 0.15 and 0.25% per day, during loading of the tanker, and can reach values as high as 150% of the normal rate immediately after loading, when the cargo tank and insulation cool down (Jaramillo et al. 2007; Anderson et al. 2009).

Conventional tankers, using steam turbine propulsion systems, could run on a range of different fuels; boil-off gas produced from the cargo tanks was compressed and burned in the boilers in place of some of the normal fuel oil, at the expense of LNG loss during transport (Lin et al. 2010). However, in the new fleet used for Qatari LNG exports, the boil-off gas is re-liquefied and returned to the cargo tanks to manage the pressure and to minimise losses during transport, albeit at the expense of power consumption for liquefaction.

At the destination port, the LNG is unloaded, stored and vaporised when needed.

1.2 Environmental impacts of using LNG

Natural gas and LNG have been advocated as a way to reduce greenhouse gas (GHG) emissions when compared to other fossil fuels, such as coal and oil (Sakmar et al. 2009; Morris and Messenger 2010). However, the LNG processing and transportation emissions are reported to be even greater than those associated with coal (PACE 2009). Once vaporised, LNG has the same environmental profile as piped natural gas but the processes of liquefaction and tanker transport need to be taken into account when assessing its overall environmental performance. As analysed in the following paragraphs, no complete and up-to-date environmental assessment of the LNG supply chain, from extraction to distribution to the end-user (e.g. domestic household), is available in the open literature for the UK.

A number of scientific studies have analysed the carbon footprint of LNG production and use in specific geographical contexts and against alternative energy supplies, including for example coal (Jaramillo et al. 2007), compressed natural gas (López et al. 2009) or also heavy fuel (Arteconi et al. 2010) and shale gas (Stamford and Azapagic 2014).

A number of analyses have addressed the LNG supply till end-user distribution to Japan: two studies (Tamura et al. 2001; Okamura et al. 2007) for example considered five exporting countries and both concluded that as average the liquefaction process only determines more than 70% of the total LNG upstream production footprint. These findings are in contrast with the results reported for the USA.

LNG supply to the USA is considered mainly from Trinidad and Tobago (Jaramillo et al. 2007; PACE 2009; NETL 2012). These cradle to gate studies pointed out that the LNG imported to the USA has a higher life cycle GHG emissions compared to domestic natural gas (from 30% (Jaramillo et al. 2007) to 85% (NETL 2012)); furthermore, the LNG processing and transportation emissions were found to represent almost 50% of the supply chain. In addition to this, fugitive emissions from LNG transport were found to be a possible source of increased GHG emissions that can even dominate the whole life cycle (Lowell et al. 2013).

European imports of LNG have also been studied but in this case the scientific literature is less homogenous and a cross comparison is more difficult. Some studies are of difficult interpretation as a result of little information reported on the base assumptions used to calculate the impact of the LNG supply chain and also on the hot spot analysis. Referring to the EU condition, Lopez et al. (López et al. 2009) reported on the greenhouse gas emissions of two different engines using three different fuels, including also compressed natural gas from LNG in Spain. In opposition to what was found for the USA, Arteconi et al. (Arteconi et al. 2010) concluded for the EU that the upstream emissions for diesel and LNG for use in heavy-duty vehicles were almost identical. The source and transportation distance are key factor for the total environmental burden of the LNG supply chain: some authors (Edwards et al. 2006; Kavalov et al. 2010) analysed the upstream (emissions before the gas use) LNG emissions for different sending and receiving ports and showed that the transportation distance can double the GHG emissions. Conversely, others (Safaei et al. 2015) focused their analysis on emissions due to the venting practice at well fields in Nigeria: the GHG emissions related to the transportation of LNG from Nigeria to Portugal can increase by 48% when considering a scenario with a higher rate of venting emissions at well fields. The conclusions for the LNG imports to the USA were confirmed by Korre et al. (Korre et al. 2012). They analysed the import of LNG to the UK from Qatar and found that almost 50% of GHG emissions before gas use were due to natural gas processing after extraction, liquefaction, LNG shipping and operations at the LNG receiving terminal whereas the GHG emissions from the offshore platform and pipeline transportation were found not to be significant. The study of Korre et al. (2012) did not consider environmental impacts other than the global warming potential nor a sensitivity analysis on key modelling assumptions of the LNG life cycle as the main focus of their paper was on alternative CCS technologies in fossil fuel power generation. Furthermore, Stamford et al. (Stamford and Azapagic 2014) presented the first and only study so far covering impact categories other than the GWP for the LNG supply. They analysed the LNG import to the UK from Qatar and Algeria; however, as the study does not state the modelling principles, technologies analysed nor the system boundaries used, its significance is somewhat difficult to analyse.

This study was undertaken to perform an attributional and hot spot analysis of LNG life cycle for quantifying the environmental burdens of LNG production, transport and distribution. The following points were addressed:

-

1.

Analysis of the LNG transport from Qatar to the UK within the Qatargas project II since the UK will have a major share on the total imports.

-

2.

Detailed hot spot analysis of the LNG supply chain (production, liquefaction, transport and distribution), especially focusing on the LNG transport as this was shown to largely influence GHG emissions. This is aimed at revealing the life cycle stages and operations having the highest environmental impacts.

-

3.

Detailed sensitivity analysis on the modelling parameters specified in the following section.

-

4.

Analysis of the contribution of fugitive emissions through the LNG supply chain as these were shown to strongly increase the GWP.

-

5.

Analysis of the LNG supply chain and its hot spot for a wide range of impact categories other than the GWP according to the CML methodology (Guinée 2002).

The results of this analysis can be used for future comparative studies with different countries and energy production technologies. The works is part of a wider assessment which has analysed UK developing energy types (Evangelisti et al. 2015a; Evangelisti et al. 2015b; Tagliaferri et al. 2016b; Tagliaferri et al. 2016a).

The modelling principles used and the technologies assumed for LNG liquefaction and transport are detailed in the following section.

2 Methods

2.1 Functional unit and system boundaries

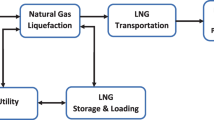

The functional unit used in this study is 1 MJ of natural gas (gross calorific value) delivered to the end-user at grid pressure, i.e. below 7 bar. As the purpose of this study is to calculate the environmental burdens of the production of natural gas when delivered to the end-user, the use phase is not included. In particular, the emissions from combustion are not considered. Figure 1 shows the operations in the supply chain included in the system analysed (system boundary). The distinction between foreground and background is used to identify direct, indirect and avoided emissions. Direct emissions arise from the foreground (the LNG supply chain) whereas indirect and avoided from the background. This assessment covers all these types of emissions. The indirect burdens are due to the upstream supply of materials and energy and waste disposal; whereas the avoided burdens are allocated to the sale of any marketable valuable by-products obtained during gas extraction (including, for example, condensables). Plant and ship construction and maintenance, as well as natural gas storage prior to ship transport, are included in the model according to the Ecoinvent database (Swiss Centre for Life Cycle Inventories 2014).

The environmental impact results of this life cycle study are calculated following the CML 2001 (Guinée 2002) Method Characterisation factors, version 4.5 (April 2015) which is based on the ISO standards (ISO 14040 2006).

The gas considered in this study is extracted from Qatar’s North Dome Gas-Condensate field located about 80 km north east of Qatar’s mainland. From here, it is sent to the industrial city of Ras Laffan through wet subsea pipelines, where it is processed and liquefied by chilling. GHG emissions from the offshore platform were not considered in this paper as already found negligible by Korre et al. (2012). The natural gas extracted in Qatar usually has a higher concentration of SOx than that from other gas fields (e.g. UK Continental Shelf gas field), so that desulphurization is essential (Okamura et al. 2007). Once at the facilities onshore, condensable components, sulphur compounds and CO2 are removed (Qatargas 2014). Of the gas reaching the liquefaction plant, 8.8% is used to meet parasitic energy demand, primarily for liquefaction (Tamura et al. 2001; Jaramillo et al. 2007; PACE 2009). The LNG is loaded onto the purpose-built tankers and transported to and unloaded at the South Hook LNG terminal at Milford Haven in South Wales. The new slow-speed diesel engines, used instead of the conventional steam turbines for the Qatari fleet, are reported to have higher fuel efficiency and lower emissions (Anderson et al. 2009); this new fleet has a cargo capacity over 50% higher than conventional carriers- from 135,000 m3 (Thomas and Dawe 2003) of the old tankers, up to 266,000 m3 for the new tankers (Anderson et al. 2009). The Q-Flex and Q-max vessels developed by Qatargas have a cargo capacity ranging from 210,000 m3 to 217,000 m3 and 263,000 m3 to 266,000 m3, respectively. Hence, this assessment is based on gas transported from Ras Laffan to South Hook, through the Suez Canal, using state-of-the-art Q-max tankers, each carrying 110,000 t of LNG, powered by slow-speed diesel engines fuelled by heavy fuel oil. Burdens associated with fuel use for propulsion cover the outward journey with the payload of LNG and the return journey under ballast conditions. The tankers have an average cruise speed of 19.5 knots (Jaramillo et al. 2007; PACE 2009; Korre et al. 2012). The distance between Ras Laffan and South Hook Terminal is 11,821 km (sea-distances.org 2014); the voyage therefore lasts less than 13 days. However, the conservative estimate of 14 days of journey time was used in the model to account for eventual delays and for the waiting time at the entry of the Suez Canal before the scheduled convoy time.

The boil-off rate of the new tankers is 0.14% of the cargo volume per day (Anderson et al. 2009) and this vapour is re-liquefied. The associated electric power requirement, 6 MW, is provided by auxiliary diesel generators. The associated emissions are based here on the most recent emission standards for marine transportation, commonly referred to as Tier II and introduced in 2008 in the Annex VI of the IMO 1997 (International-Maritime-Organization 2005). Power requirements for re-liquefaction on the return journey at ballast condition are considered negligible and not included in the inventory.

Vaporisation facilities are the last step the LNG must go through before going into the pipeline system in the UK. On arrival at the LNG terminal, the LNG is pumped ashore into insulated tanks, where it is stored at approximately −160 °C and atmospheric pressure (South-Hook-LNG 2014). When needed for injection into the National Transmission System, the LNG is pumped to heated vaporisers (National-grid 2006). Operating the vaporisers uses typically 3% of the gas entering the terminal (Ruether et al. 2005; Jaramillo et al. 2007).

The key inventory data and emissions are summarised in Tables 1 and 2, respectively; details are given in the Electronic Supplementary Material. The inventory is mainly based on literature data, primarily the Ecoinvent database (Swiss Centre for Life Cycle Inventories 2014) updated according to more recent data and modified for the specific case assessed here as specified in the Electronic Supplementary Material.

2.2 Scenarios

To assess the robustness of the results, the sensitivity analysis focuses on parameters for transport, liquefaction and evaporation:

-

1.

Emissions due to the propulsion of the diesel engine

-

2.

Tanker volume

-

3.

Shipping distance

-

4.

Energy requirements for the liquefaction process

-

5.

Energy requirements for the vaporisation process

-

6.

Fuel used for propulsion

-

7.

Acid gases and sulphur removal

The scenarios explored are summarised in Table 2:

-

S.0. Base scenario, using the assumptions reported above.

-

S.1-S.2. These scenarios explore different emission levels from the propulsion engines of the tanker: respectively 5/7 and 9/7 times the values in the base case were considered to account for higher and lower fuel and off gas cleaning efficiency.

-

S.3-S.4. The capacity of the tanker is changed from 210,000 to 266,000 m3, to represent the minimum and the maximum capacity of the new tanker ships.

-

S.5-S.6. Different transport distances are considered: 15,000 km in S5 and 5000 km in S6, compared with 11,821 km in the base case, to represent the maximum and minimum distances to Europe from Qatar: 5000 km is the approximate distance between Qatar and the Northern end of the Suez Canal, whilst 15,000 is the approximate distance from Qatar through the Suez Canal to the most northerly European countries (including Norway and Lithuania).

-

S.7-S.8 and S.9-S.10. Changes in the liquefaction and vaporisation energy requirements are explored (5 to 15% of the gas reaching the liquefaction plant and 1 to 5% of the gas reaching the evaporation plant).

-

S.11. The tanker main propellers and auxiliaries are assumed to be powered by marine gas oil (MGO) instead of diesel oil (HFO).

-

S.12.The sweetening process is not included in this scenario, representing a possible case in which the natural gas extracted is sweet and does not require acid gases removal.

In addition, in section 5, different rates of methane leaks in the LNG supply chain and the exclusion of the re-liquefaction system were discussed. These were not considered as additional scenarios because they represent cases not allowed by the current legislation and the design of the Qatari fleet, respectively. However, this analysis shows what the potential threat of unwanted methane emissions is on the GWP.

3 Results and discussion

All results are reported per functional unit of 1 MJ natural gas delivered to the end-user. The environmental burdens of the base scenario were normalised according to the normalisation factors of the CML, IPCC, ReCiPe (region equivalents, EU25 + 3, year 2000) (Thinkstep 2015) method and the results are reported in Table 3. The normalised results show that the most significant impacts are global warming potential (GWP), human toxicity potential (HTP), fresh water aquatic ecotoxicity potential (FAETP), abiotic depletion potential (ADP), photochemical ozone creation potential (POCP), and acidification potential (AP). As better highlighted later in the result discussion, both AP and POCP are strongly influenced by the sulphur content of the treated gas. Conversely, the burdens associated with GWP, FAETP and HTP are more uniformly distributed among the operations included in the system boundaries, and finally, the ADP is driven by the depletion of the fossil resource of natural gas. The absolute results of the hot spot analysis are reported in Fig. 2 and percentage contributions are shown in the Electronic Supplementary Material.

Global Warming Potential (GWP) (see Fig. 2e)

All parameters affect the results but the major variations from the base case are shown for S.6 and S.7 and S.12. The GWP of the extraction and drying and the sweetening processes are the same for all scenarios. The same is also valid for the GWP of the liquefaction process except for S.7 and S.8. Doubling or halving the energy requirement compared to the base scenario significantly changes the GWP of the liquefaction process—the GWP of the liquefaction process is 9.4 × 10−3 kg of CO2 eq. for S.7 and 3.4 × 10−3 kg of CO2 eq. for S.8 compared to 5.71 × 10−3 kg of CO2 eq. of S.0. The GWP of the LNG transport depends mainly on the direct emissions from the diesel engine and shipping distance (the direct activities determine almost 87% of the GWP associated with transport in S.0). The processes of liquefaction, LNG transport and evaporation determine more than 50% of the total GWP. In particular, the GWP of the liquefaction process is due to direct emission from energy use and leakage of refrigerants. The GWP of the evaporation process almost doubles between S.9 (1.5 × 10−3 kg of CO2 eq.) and S.10 (3.7 × 10−3 kg of CO2 eq.), as a result of different energy requirements. For all scenarios, almost 18% of the total GWP is due to the distribution of the evaporated gas.

The total GWP calculated in this study for the upstream processing (including extraction and drying, liquefaction, transport and evaporation but not distribution) equals 0.0174 kg of CO2 eq., and this value is consistent with values already reported in literature ~0.016–0.018 kg of CO2 eq by (Tamura et al. 2001; Edwards et al. 2006; Venkatesh et al. 2011; NETL 2012; Safaei et al. 2015).

Fresh Water Aquatic Ecotoxicity Potential (FAETP) (see Fig. 2d)

The variation of the results from the base scenario, except for S.5, S.6 and S.12, is negligible as it is always lower than 1%. The shipping distance is the parameter that determines a substantial variation of the results in S.5 and S.6 (+10 and −16% from the base scenario for S.5 and S.6, respectively). About 18% of the total FAETP is due to the emission to fresh water occurring during the extraction and drying process. The burdens allocated to the sweetening process and to the liquefaction process are mainly due to the indirect activities linked to the production of the processing plants—for S.0, 88 and 93% of the total FAETP of sweetening and liquefaction, respectively, are due to the production of the processing plants. Transport of LNG always determines 30% of the total FAETP except for S.5 and S.6 (35 and 16%, respectively). The burden due to the transport of LNG is equally distributed between outward and inward journey, and this is due to the operation and maintenance of the sending ports (this represents 64% of the total burden due to transport for S.0). The evaporation process determines between 10 and 15% of the total FAETP. About 13% of which is due to the distribution of vaporised natural gas to the end-user. Pipeline construction and installation determine the main burden allocated to the distribution.

Abiotic Depletion Potential (ADP) (see Fig. 2a)

This indicator does not strongly depend on the parameters analysed in the sensitivity analysis. S.12 shows a lower ADP because the sweetening is not considered and hence the total energy requirements for processing are lower. S.12 shows a variation from the base scenario lower than 5%. For all the scenarios, more than 95% of the ADP is due to the depletion of natural gas associated with gas extraction. As in this particular study, the depletion of fossil resources is under study; the normalised ADP of Table 3 shows the highest contribution compared to all other indicators.

Acidification Potential (AP) (see Fig. 2b)

For all the scenarios analysed, except for S.12, more than 75% of the total AP is due to the sweetening of the natural gas before liquefaction. This value increases to 83% for S.6 as a result of the lower environmental burden associated to transport (shorter transport distance is assumed for this scenario). In S.0, the emissions due to the use of sour gas for energy requirements in a gas turbine during the removal of S determine 86% of the AP of the total sweetening process. The burden of the liquefaction process is due to the indirect activities associated with the production of its energy requirements (that is the production and processing of the natural gas used within the liquefaction process). The LNG transport contributes between 3.1 and 9% (for S.6 and S.5, respectively) to the total AP thanks to the strict limits that regulate the sulphur content of the fuel oils. Except for S.12, the sensitivity analysis shows a negligible variation in the results—the min and max value of the AP are 2.13–4 kg of SO2 eq. and 2.33−4 kg of SO2 eq., respectively, for S.6 and S.7, corresponding to a −3.8 and +5.1% variation from the base scenario. When the extracted gas is assumed to be sweet (S.12), a deep pre-processing including sulphur and acid gas removal is not included in the assessment and hence, the AP dramatically decreases. In this case, LNG transport (the direct emissions to environment) and liquefaction are major contributions to AP.

Photochemical Ozone Creation Potential (POCP) (see Fig. 2h)

This indicator is driven by the direct emissions associated to the gas sweetening. Conversely, the burden allocated to the liquefaction process is associated to the indirect emission due to the processing of the natural gas used for energy requirements. The burden allocated to the evaporation process is negligible. Negligible variation of the results is shown for the sensitivity analysis, except for S.12. For all scenarios, except for S.12, about 11–12% of the total POCP is due to the extraction and distribution of the vaporised natural gas.

Eutrophication Potential (EP) (see Fig. 2c)

S.5 shows the highest EP because of the longer transport distance, whereas the lowest burden is shown for S.6 because of the lower transport distance (+13 and −23% from the base scenario, respectively). Transport always determines between 25 and 49% of the total EP (lowest value of 25% is reported for S.5). The burden for transport is prevalently allocated to the direct emissions from diesel engines used for propulsion and auxiliaries (that includes the re-liquefaction systems). For all scenarios, except S.11, the sweetening process always determine about 10% of the total EP and in particular this is due to the direct emission due to the burning of sour gas used as energy source for the process. The extraction and drying of gas determines up to 23% (for S.6) of the total EP. Conversely, the evaporation process determines between 7.5 and 15% of the total EP (for S.10 and S.6, respectively). This is due to the indirect emissions allocated to the processing of the natural gas used for the energy requirements (58% of the total evaporation EP) and to the production and maintenance of the evaporation plant (35% of the total evaporation EP). The distribution of the vaporised LNG in the UK causes around 10% of the total EP.

The ODP (Fig. 2g), HTP (Fig. 2f) and TEPT (Fig. 2i) do not change significantly throughout the scenarios and are therefore discussed in the Electronic Supplementary Material.

4 Discussion

Table 4 shows the direct emissions due to the shipping of LNG according to the delivery of 1 Nm3 of LNG at the receiving terminal for the base scenario. The previous discussion on the different environmental impacts accounted for the use of re-liquefaction systems; Table 4 shows the emissions included in the base model and the potential emissions in case re-liquefaction is not used. If the re-liquefaction system is not included, the emissions of CO2, CO and NOx are reduced by a tiny amount (see Table 4) as a result of the lower amount of energy required by the auxiliaries (i.e. by the lower amount of fuel burnt in the auxiliary engines). Conversely, the potential methane emissions significantly increase because of the boiled off gas. In this case, the boil-off gas needs to be used as fuel to reduce the GWP. However, given that the new diesel engines of the newer tanker ships do not run using methane but use HFO, in this case, the re-liquefaction system is a necessary requirement in order to limit the GWP and not emit flared vaporised gas into the atmosphere.

Furthermore, the effect of possible fugitive methane emissions along the supply chain has been analysed. These emissions can be critical for operations such as extraction, liquefaction, storage before transport, transport itself and evaporation. On the basis of 1 MJ of gas delivered to the end-user as a functional unit, when 1% of the total gas delivered is vented as methane leakage throughout the supply chain, the GWP increases by 15% compared to the GWP for the base scenario. The variation of the GWP increases to 78% compared to the base scenario when 5% of the delivered gas is considered to be lost as vented emissions. These variations of the results range between 2 and 9% if a flaring system is considered to abate methane leakage. This analysis confirms the extremely dangerous effect of fugitive methane emissions on the total GWP of the LNG supply chain.

Furthermore, for the base scenario, the relevance of the upstream emissions in the context of a whole life cycle (including also the gas use phase) has been considered. The upstream emissions of the LNG supply chain, including extraction and drying, liquefaction, transport, evaporation and pipe distribution to the end-user, cause 36% of the total cradle to grave GWP which also include the use phase.

The GWP obtained in this study (Section 4) is compared to the GWP reported in other literature studies (chosen on the base of transparency in the inventory data and result values), as shown in Fig. 3 (the base cases of literature studies have been used for comparison). To make a fair comparison with the literature studies, sweetening and distribution in pipes are not considered in the value reported for this study in Fig. 3. As far as possible, data for the GWP on the LNG upstream production have been collected according to four categories—extraction and drying, liquefaction, transport and evaporation-—from literature (Tamura et al. 2001; Edwards et al. 2006; Okamura et al. 2007; López et al. 2009; Kavalov et al. 2010; Arteconi et al. 2010; Venkatesh et al. 2011; NETL 2012; Safaei et al. 2015). The results reported in Fig. 3 are strictly correlated to the assumptions used as the basis of each analysis; however, the GWP obtained in this study is the same order of magnitude as the results previously reported. Extraction and drying are shown to determine a significant contribution to the GWP although not the main one; in Safei et al. (Safaei et al. 2015), the contribution of extraction and drying is the highest as a result of the assumption of flaring emissions at LNG fields in Nigeria and releasing of fuel emissions. For all the studies analysed, the liquefaction process determines a relatively high contribution to the total upstream life cycle of LNG. Conversely, the emissions due to the evaporation process are not the main cause of GWP in the LNG life cycle. As also highlighted in the sensitivity analysis of this study, the shipping distance of the LNG is a key factor for the emissions associated with transport. Studies considering longer transport distance, for example from Middle East to North of Europe (Kavalov et al. 2010), show a higher GWP.

Korre et al. (2012) are alone in analysing the impact of the LNG supply to the UK from Qatar. Their GWP estimate (circa 7 g of CO2 eq/MJ of natural gas) is less than half than the estimated GWP reported in our study; however, the results of the GWP reported in our study qualitatively confirm what is already found in literature (Korre et al. 2012; Safaei et al. 2015). In fact, the present analysis which has also been expanded to other environmental impacts shows that both direct and indirect burdens specific for the LNG supply (that are deep processing–sweetening of the sour gas, liquefaction, transport and evaporation) cannot be considered negligible when considering the supply of natural gas for future energy scenarios.

The parameters that mainly influence the results are liquefaction energy, the shipping distance, the tanker volume, the evaporation energy and potential methane leakage. A change in the tanker volume means a change in the amount of gas transported and hence, a higher/lower environmental impact per MJ of gas—the higher energy requirements of a bigger tank are offset by the higher amount of LNG transported. Conversely, a longer or smaller shipping distance significantly changes the amount of energy and emissions during transport. As far as the use of bigger engineered tanks to reduce the environmental impact is a costly but achievable solution, the burden due to the distance of LNG shipping to the UK from Qatar cannot be changed.

Finally, the impacts of the distribution of the vaporised gas to the end-user at low pressure cannot be considered negligible and it is mainly due to the construction, installation and maintenance of the pipes and also to the energy requirements and emission from piping.

5 Conclusions

LNG is reported to be an increasing supply of energy for the UK whilst the national reserves of the continental shelf are diminishing. Qatar is increasing the export of LNG thanks to world-wide ventures and to the improvement of LNG technologies. As a case study, the environmental impacts of the LNG supply to the UK within the new project Qatargas II were analysed. New tanker ships and facilities were assumed to be used in the analysis. The life cycle of the LNG supply chain, from the gas extraction to the distribution to the consumer, has been included in the assessment. The main findings of this study highlight how the operations specifically associated with LNG, that includes liquefaction, transport and vaporisation, significantly influence the environmental impact of the cradle to gate supply chain and hence they cannot be considered negligible in a complete environmental assessment. The EP, FAETP and GWP are particularly affected by these three life cycle steps. On the other hand, the AP and POCP strongly depend on the sweetening process and hence on the composition of the gas to be processed. The ODP is affected by pipe distribution after vaporisation. The sensitivity analysis has explored the influence of some key parameters, such as energy requirements of the liquefaction and vaporisation processes, fuel for propulsion, days of navigation (that is shipping distance), tanker volume and sweetening process. The last three parameters determine the main variation in the results. The case study here reported highlights how (i) long-distance LNG transport and (ii) natural gas processing, including sweetening, liquefaction and vaporisation, are the key aspects that alter the total environmental burdens. Except for ADP, for all the scenarios and the indicators analysed, the extraction and drying of natural gas shows limited impact to the total environmental burden of the LNG supply chain. Fugitive emissions that might occur during LNG loading, transport and unloading must strictly be avoided to reduce the impact on global warming. In fact, leakage of 5% of the gas delivered to the end-user can increase the GWP by 78%.

References

Anderson M, Salo K, Fridell E (2015) Particle- and gaseous emissions from an LNG powered ship. Environ Sci Technol 49:12568–12575

Anderson TN, Ehrhardt ME, Foglesong RE, Bolton T (2009) Shipboard reliquefaction for large LNG carriers. In: Proceedings of the 1st Annual Gas Processing Symposium, pp 1–8

Arteconi A, Brandoni C, Evangelista D, Polonara F (2010) Life-cycle greenhouse gas analysis of LNG as a heavy vehicle fuel in Europe. Appl Energy 87:2005–2013

Bosma P, Nagelvoort RK (2009) Liquefaction technology; Developments through history. In: Proceedings of the 1st Annual Gas Processing Symposium, pp 1–13

DECC (2014) Maintaining UK energy security. 2014. https://www.gov.uk/government/policies/maintaining-uk-energy-security--2/supporting-pages (Last accessed 3 February 2016)

Edwards R, Larivé JF, Rickeard D et al. (2006) Well-to wheels analysis of future automotive fuels and powertrains in the European context

European Commission (2014) Clean fuels for transport: member states now obliged to ensure minimum coverage of refuelling points for EU-wide mobility. http://europa.eu/rapid/press-release_IP-14-1053_en.htm. Accessed 17 Feb 2016

Evangelisti S, Tagliaferri C, Clift R et al (2015a) Life cycle assessment of conventional and two-stage advanced energy-from-waste technologies for municipal solid waste treatment. J Clean Prod 100:212–223

Evangelisti S, Tagliaferri C, Clift R et al (2015b) Integrated gasification and plasma cleaning for waste treatment: a life cycle perspective. Waste Manag 43:485–496

Guinée JB (2002) Handbook on life cycle assessment, operational guide to the ISO standards. Kluwer Aca, Dordrecht

Harvey F (2013) British gas owner secures £4.4bn deal with Qatar for four-year LNG supply. https://www.theguardian.com/business/2013/nov/06/british-gas-centrica-deal-imports-qatar

International-Maritime-Organization (2005) IMO International Convention for the Prevention of Pollution from Ships (MARPOL). http://www.imo.org/About/Conventions/ListOfConventions/Pages/International-Convention-for-the-Prevention-of-Pollution-from-Ships-(MARPOL).aspx

ISO 14040 (2006) International Organization for Standardization, Geneva, Switzerland, In: Environmental management—life cycle assessment—principles and framework. https://www.iso.org/standard/37456.html (Last accessed 6th March 2016)

Jaramillo P, Griffin WM, Matthews HS (2007) Comparative life-cycle air emissions of coal, domestic natural gas, LNG, and SNG for electricity generation. Environ Sci Technol 41:6290–6296

Kavalov B, Petrić H, Georgakaki A (2010) Liquefied NG for Europe—some important issues for consideration. http://ec.europa.eu/dgs/jrc//downloads/jrc_reference_report_200907_liquefied_natural_gas.pdf. Accessed 19 Mar 2015

Korre A, Nie Z, Durucan S (2012) Life cycle assessment of the natural gas supply chain and power generation options with CO 2 capture and storage: assessment of Qatar natural gas production, LNG transport and power generation in the UK. Sustain Technol Syst Policies 11:1–11

Kumar S, Kwon H-T, Choi K-H et al (2011) LNG: an eco-friendly cryogenic fuel for sustainable development. Appl Energy 88:4264–4273

Lin W, Zhang N, Gu A (2010) LNG (liquefied natural gas): a necessary part in China’s future energy infrastructure. Energy 35:4383–4391

López JM, Gómez Á, Aparicio F, Javier Sánchez F (2009) Comparison of GHG emissions from diesel, biodiesel and natural gas refuse trucks of the City of Madrid. Appl Energy 86:610–615

Lowell D, Wang H, Lutsey N (2013) Assessment of the fuel cycle impact of liquefied natural gas as used in international shipping. http://www.theicct.org/sites/default/files/publications/ICCTwhitepaper_MarineLNG_130513.pdf

Moorhouse J, Glave J, Kilpatrick J (2015) A clean energy and jobs plan for British Columbia. http://cleanenergycanada.org/work/a-clean-economy-and-jobs-plan-for-british-columbia/. Accessed 20 Apr 2016

Morris A, Messenger K (2010) A report to Department of Energy and Climate Change GB Gas security of supply and options for improvement march 2010. https://www.gov.uk/government/uploads/system/uploads/attachment_data/file/47872/114-poyry-gb.pdf

National Grid (2014) UK future energy scenarios. http://www2.nationalgrid.com/uk/industry-information/future-of-energy/future-energy-scenarios/. Accessed 13 May 2016

National-grid (2006) Safety data sheet natural gas. http://www.co-gassafety.co.uk/downloads/March2010/National_Grid_Natural_Gas_Pre_Combustionpdf

NETL (2012) Life cycle analysis: natural gas combined cycle (NGCC) power plant. http://www.netl.doe.gov/FileLibrary/Research/Energy Analysis/Publications/NGCC-LCA---Final-Report---Report---9-10-12---Final---Version.pdf. Accessed 19 Mar 2015

Okamura T, Furukawa M, Ishitani H (2007) Future forecast for life-cycle greenhouse gas emissions of LNG and city gas 13A. Appl Energy 84:1136–1149

PACE (2009) Life cycle assessment of GHG emissions from LNG and coal fired generation scenarios: assumptions and results. http://www.lngfacts.org/resources/LCA_Assumptions_LNG_and_Coal_Feb09.pdf

Qatargas (2014) Qatargas website. https://www.qatargas.com/

Ruether J, Ramezan M, Grol E (2005) Life-cycle analysis of greenhouse gas emissions for hydrogen fuel production in the United States from LNG and coal. http://www.netl.doe.gov/FileLibrary/Research/Energy Analysis/LifeCycle Analysis/h2_from_coal_lng_final.pdf

Safaei A, Freire F, Henggeler Antunes C (2015) Life-cycle greenhouse gas assessment of Nigerian liquefied natural gas addressing uncertainty. Environ Sci Technol 49:3949–3957

Sakmar SL, Ll M, Kendall DR (2009) The globalization of LNG markets: historical context, current trends and prospects for the future. In: Proceedings of the 1st Annual Gas Processing Symposium, pp 1–12

sea-distances.org (2014) Sea-Distances

South-Hook-LNG (2014) The regasification process at South Hook LNG. https://www.southhooklng.com/operations/what-we-do/

Stamford L, Azapagic A (2014) Life cycle environmental impacts of UK shale gas. Appl Energy 134:506–518

Swiss Centre for Life Cycle Inventories (2014) Ecoinvent: the life cycle inventory data, Version 3.0. Swiss Centre for Life Cycle Inventories, Duebendorf

Tagliaferri C, Clift R, Lettieri P, Chapman C (2016a) Shale gas: a life-cycle perspective for UK production. Int J Life Cycle Assess. doi:10.1007/s11367-016-1207-5

Tagliaferri C, Evangelisti S, Clift R et al (2016b) Life cycle assessment of conventional and advanced two-stage energy-from-waste technologies for methane production. J Clean Prod 129:144–158

Tamura I, Tanaka T, Kagajo T et al (2001) Life cycle CO2 analysis of LNG and city gas. Appl Energy 68:301–319

Thinkstep (2015) GaBi 6 software-system and databases for life cycle engineering. Stuttgart, Echterdingen (see www.pe-europe.com)

Thomas S, Dawe RA (2003) Review of ways to transport natural gas energy from countries which do not need the gas for domestic use. Energy 28:1461–1477

Ursan M (2011) What is boil-off? In: LNG task force Meet. Brussels. http://www.unece.org/fileadmin/DAM/trans/doc/2011/wp29grpe/LNG_TF-02-06e.pdf. Accessed 9 Jun 2015

Venkatesh A, Jaramillo P, Griffin WM, Matthews HS (2011) Uncertainty in life cycle greenhouse gas emissions from United States natural gas end-uses and its effects on policy. Environ Sci Technol 45:8182–8189

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Christian Bauer

Electronic supplementary material

ESM 1

(DOCX 92 kb)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Tagliaferri, C., Clift, R., Lettieri, P. et al. Liquefied natural gas for the UK: a life cycle assessment. Int J Life Cycle Assess 22, 1944–1956 (2017). https://doi.org/10.1007/s11367-017-1285-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-017-1285-z