Abstract

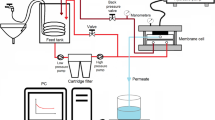

For sustainable water management, the treatment and reuse of industrial wastewater are becoming increasingly important. There have been many studies on color removal, especially from textile wastewater. However, there are deficiencies in the literature regarding highly alkaline caustic recovery and reuse in the plant. For this reason, this study examines caustic-containing textile wastewater treatment and the reuse potential of the obtained caustic chemicals with a pilot-scale ceramic membrane system. During operations, only an ultrafiltration membrane, a nanofiltration membrane, and combined ultrafiltration + nanofiltration membranes were put to use. Chemical oxygen demand, total hardness, color, total organic carbon, sodium ion concentration, and pH tests were applied to samples, and temperature and flux were recorded throughout all operations. The obtained results showed that for ultrafiltration + nanofiltration cycles, the overall average removal efficiencies were 67, 71, 42, and 92% for total organic carbon, chemical oxygen demand, total hardness, and color respectively. For only ultrafiltration cycles, the overall average removal efficiencies were 22, 36, 25, and 63% for total organic carbon, chemical oxygen demand, total hardness, and color, respectively. Sodium values in the input wastewater were around 12 mg/L on average, and nanofiltration membrane output values changed to between 7 and 11 mg/L. Based on the sodium concentration differences between inflow and outflow samples, the permeate of ceramic membrane systems has potential for reuse in facilities.

Similar content being viewed by others

Data Availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Alventosa-deLara E, Barredo-Damas S, Alcaina-Miranda MI, Iborra-Clar MI (2012) Ultrafiltration technology with a ceramic membrane for reactive dye removal: optimization of membrane performance. J Hazard Mater 209–210:492–500. https://doi.org/10.1016/j.jhazmat.2012.01.065

Barredo-Damas S, Alcaina-Miranda MI, Bes-Piá A, Iborra-Clar MI, Iborra-Clar A, Mendoza-Roca JA (2010) Ceramic membrane behavior in textile wastewater ultrafiltration. Desalination 250:623–628. https://doi.org/10.1016/j.desal.2009.09.037

Barredo-Damas S, Alcaina-Miranda MI, Iborra-Clar MI, Mendoza-Roca JA, Gemma M (2011) Effect of pH and MWCO on textile effluents ultrafiltration by tubular ceramic membranes. Desalin Water Treat 27:81–89. https://doi.org/10.5004/dwt.2011.2057

Bisschops I, Spanjers H (2003) Literature review on textile wastewater characterisation. Environ Technol 24:1399–1411. https://doi.org/10.1080/09593330309385684

Choe EK, Son EJ, Lee BS, Jeong SH, Shin HC, Choi JS (2005) NF process for the recovery of caustic soda and concentration of disodium terephthalate from alkaline wastewater from polyester fabrics. Desalination 186:29–37. https://doi.org/10.1016/j.desal.2005.04.056

Cinperi NC, Ozturk E, Yigit NO, Kitis M (2019) Treatment of woolen textile wastewater using membrane bioreactor, nanofiltration and reverse osmosis for reuse in production processes. J Clean Prod 223:837–848. https://doi.org/10.1016/j.jclepro.2019.03.166

de Oliveira Neto GC, Ferreira Correia JM, Silva PC, de Oliveira Sanches AG, Lucato WC (2019) Cleaner production in the textile industry and its relationship to sustainable development goals. J Clean Prod 228:1514–1525. https://doi.org/10.1016/j.jclepro.2019.04.334

Dilaver M, Hocaoğlu SM, Soydemir G, Dursun M, Keskinler B, Koyuncu İ, Ağtaş M (2018) Hot wastewater recovery by using ceramic membrane ultrafiltration and its reusability in textile industry. J Clean Prod 171:220–233. https://doi.org/10.1016/j.jclepro.2017.10.015

European Commission (EC) (2003) Integrated Pollution Prevention and Control (IPPC) Reference Document on Best Available Techniques for the Textile Industry (BREF). EC IPPC Bureau, Seville

Fersi C, Gzara L, Dhahbi M (2005) Treatment of textile effluents by membrane technologies. Desalination 185:399–409. https://doi.org/10.1016/j.desal.2005.03.087

Gao W, Liang H, Ma J, Han M, Chen ZL, Han ZS, Li GB (2011) Membrane fouling control in ultrafiltration technology for drinking water production: a review. Desalination 272:1–8. https://doi.org/10.1016/j.desal.2011.01.051

Guo S, Wan Y, Chen X, Luo J (2020) Loose nanofiltration membrane custom-tailored for resource recovery. Chem Eng J 409:127376. https://doi.org/10.1016/j.cej.2020.127376

Harane RS, Adivarekar RV (2017) Sustainable processes for pre-treatment of cotton fabric. Text Cloth Sustain 2. https://doi.org/10.1186/s40689-016-0012-7

Hubbe MA, Metts JR, Hermosilla D et al (2016) Pulp & paper effluent. BioResources 11:7953–8091

Hussain T, Wahab A (2018) A critical review of the current water conservation practices in textile wet processing. J Clean Prod 198:806–819. https://doi.org/10.1016/j.jclepro.2018.07.051

Issaoui M, Limousy L, Lebeau B, Bouaziz J, Fourati M (2017) Manufacture and optimization of low-cost tubular ceramic supports for membrane filtration: application to algal solution concentration. Environ Sci Pollut Res 24:9914–9926. https://doi.org/10.1007/s11356-016-8285-6

Kamali M, Costa ME, Aminabhavi TM, Capela I (2019a) Sustainability of treatment technologies for industrial biowastes effluents. Chem Eng J 370:1511–1521. https://doi.org/10.1016/j.cej.2019.04.010

Kamali M, Suhas DP, Costa ME, Capela I, Aminabhavi TM (2019b) Sustainability considerations in membrane-based technologies for industrial effluents treatment. Chem Eng J 368:474–494. https://doi.org/10.1016/j.cej.2019.02.075

Kiani R, Mirzaei F, Ghanbari F, Feizi R, Mehdipour F (2020) Real textile wastewater treatment by a sulfate radicals-advanced oxidation process: peroxydisulfate decomposition using copper oxide (CuO) supported onto activated carbon. J Water Process Eng 38:101623. https://doi.org/10.1016/j.jwpe.2020.101623

Korenak J, Hélix-Nielsen C, Bukšek H, Petrinić I (2019) Efficiency and economic feasibility of forward osmosis in textile wastewater treatment. J Clean Prod 210:1483–1495. https://doi.org/10.1016/j.jclepro.2018.11.130

Kuleyin A, Gök A, Akbal F (2020) Treatment of textile industry wastewater by electro-Fenton process using graphite electrodes in batch and continuous mode. J Environ Chem Eng 9:104782. https://doi.org/10.1016/j.jece.2020.104782

Liu G, Liu Y, Shi H, Qian Y (2004) Application of inorganic membranes in the alkali recovery process. Desalination 169(2):193–205. https://doi.org/10.1016/j.desal.2004.08.017

Moazzem S, Wills J, Fan L, Roddick F, Jegatheesan V (2018) Performance of ceramic ultrafiltration and reverse osmosis membranes in treating car wash wastewater for reuse. Environ Sci Pollut Res 25:8654–8668. https://doi.org/10.1007/s11356-017-1121-9

Ordóñez R, Hermosilla D, Pío IS, Blanco Á (2011) Evaluation of MF and UF as pretreatments prior to RO applied to reclaim municipal wastewater for freshwater substitution in a paper mill: a practical experience. Chem Eng J 166:88–98. https://doi.org/10.1016/j.cej.2010.10.016

Ordóñez R, Hermosilla D, Merayo N, Gascó A, Negro C, Blanco Á (2014) Application of multi-barrier membrane filtration technologies to reclaim municipal wastewater for industrial use. Sep Purif Rev 43:263–310. https://doi.org/10.1080/15422119.2012.758638

Ozturk E, Cinperi NC (2018) Water efficiency and wastewater reduction in an integrated woolen textile mill. J Clean Prod 201:686–696. https://doi.org/10.1016/j.jclepro.2018.08.021

Park JY, Song S (2019) Effect of pH and polypropylene beads in hybrid water treatment process of alumina ceramic microfiltration and PP beads with air back-flushing and UV irradiation. Environ Sci Pollut Res 26:1142–1151. https://doi.org/10.1007/s11356-017-9635-8

Schlesinger R, Götzinger G, Sixta H, Friedl A, Harasek M (2006) Evaluation of alkali resistant nanofiltration membranes for the separation of hemicellulose from concentrated alkaline process liquors. Desalination 192:303–314. https://doi.org/10.1016/j.desal.2005.05.031

Son EJ, Choe EK, Kim JW (2000) Nanofiltration membrane technology for caustic soda recovery. Text Chem Color Am Dyest Rep 32:46–52

Tunç MS, Yılmaz L, Yetiş Ü, Çulfaz-Emecen PZ (2014) Purification and concentration of caustic mercerization wastewater by membrane processes and evaporation for reuse. Sep Sci Technol 49:1968–1977. https://doi.org/10.1080/01496395.2014.914039

Varol C, Uzal N, Dilek FB, Kitis M, Yetis U (2015) Recovery of caustic from mercerizing wastewaters of a denim textile mill. Desalin Water Treat 53:3418–3426. https://doi.org/10.1080/19443994.2014.934116

Yang J, Lee CPD, Kim S (2007) Recovery of caustic soda in textile mercerization by combined membrane filtration Korea Institute of Industrial Technology, Chonan 330-825, South Korea, sykim@kitech.re.kr. 4:660–663

Zebić Avdičević M, Košutić K, Dobrović S (2017) Effect of operating conditions on the performances of multichannel ceramic UF membranes for textile mercerization wastewater treatment. Environ Technol (United Kingdom) 38:65–77. https://doi.org/10.1080/09593330.2016.1186225

Zebić Avdičević M, Košutić K, Dobrović S (2019) Performance evaluation of different membrane types in the textile mercerization wastewater treatment. Water Environ J 33:203–213. https://doi.org/10.1111/wej.12391

Acknowledgements

The authors are thankful for the financial support provided by the Scientific and Technological Research Council of Turkey (TÜBİTAK) (Grant No. 114Y498).

Funding

This study was supported by the Scientific and Technological Research Council of Turkey (TÜBİTAK) (Grant No. 114Y498).

Author information

Authors and Affiliations

Contributions

MA conducted all the experiments, wrote the manuscript, and evaluated the results. ÖY contributed to pilot-scale experiments. MD contributed to the evaluation of the experimental results and the corrections of the manuscript. KA provided consultancy throughout the entire study. İK provided consultancy throughout the entire study and contributed to corrections of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Angeles Blanco

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ağtaş, M., Yılmaz, Ö., Dilaver, M. et al. Pilot-scale ceramic ultrafiltration/nanofiltration membrane system application for caustic recovery and reuse in textile sector. Environ Sci Pollut Res 28, 41029–41038 (2021). https://doi.org/10.1007/s11356-021-13588-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-13588-0