Abstract

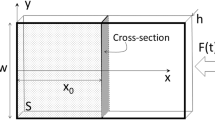

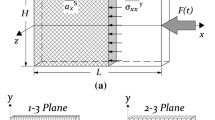

Current high strain rate testing procedures of materials are limited by poor instrumentation which leads to the requirement for stringent assumptions to enable data processing and constitutive model identification. This is the case for instance for the well known Split Hopkinson Pressure Bar (SHPB) apparatus which relies on strain gauge measurements away from the deforming sample. This paper is a step forward in the exploration of novel tests based on time and space resolved kinematic measurements obtained through ultra-high speed imaging. The underpinning idea is to use acceleration fields obtained from temporal differentiation of the full-field deformation maps measured through techniques like Digital Image Correlation (DIC) or the grid method. This information is then used for inverse identification with the Virtual fields Method. The feasibility of this new methodology has been verified in the recent past on a few examples. The present paper is a new contribution towards the advancement of this idea. Here, inertial impact tests are considered. They consist of firing a small steel ball impactor at rectangular free standing quasi-isotropic composite specimens. One of the main contributions of the work is to investigate the issue of through-thickness heterogeneity of the kinematic fields through both numerical simulations (3D finite element model) and actual tests. The results show that the parasitic effects arising from non-uniform through-the-thickness loading can successfully be mitigated by the use of longer specimens, making use of Saint-Venant’s principle in dynamics.

Similar content being viewed by others

References

Field J, Walley S, Proud W, Goldrein H, Siviour C (2004) Review of experimental techniques for high rate deformation and shock studies. Int J Impact Eng 30(7):725–775

Hopkinson B (1914) A method of measuring the pressure produced in the detonation of high explosives or by the impact of bullets. Phil Trans R Soc A 213:437–456

Kolsky H (1949) An investigation of the mechanical properties of materials at very high rates of loading. Philos Trans R Soc B 62:676–700

Gerlach R, Kettenbeil C, Petrinic N (2012) A new split Hopkinson tensile bar design. Int J Impact Eng 50:63–67

Mousavi S, Welch K, Valdek U, Lundberg B (2005) Non-equilibrium split Hopkinson pressure bar procedure for non-parametric identification of complex modulus. Int J Impact Eng 31(9):1133–1151

Sutton M, McNeill S, Helm J, Yuh J (2000) Advances in two-dimensional and three-dimensional computer vision, Photomechanics. Top Appl Phys:323–372

Surrel Y (2000) Fringe analysis, Photomechanics. Top Appl Phys 77:55–99

Gilat A, Schmidt T, Walker A (2008) Full field strain measurement in compression and tensile split Hopkinson bar experiments. Exp Mech 49(2):291–302

Koerber H, Xavier J, Camanho P (2010) High strain rate characterisation of unidirectional carbon-epoxy IM7-8552 in transverse compression and in-plane shear using digital image correlation. Mech Mater 42(11):1004–1019

Luo H, Lu H, Leventis N (2006) The compressive behavior of isocyanate-crosslinked silica aerogel at high strain rates. Mech Time-Depend Mater 10(2):83–111

Ienny P, Caro-Bretelle A, Pagnacco E (2009) Identification from measurements of mechanical fields by finite element model updating strategies. Eur J of Comput Mech 18(3-4):353–376

Grédiac M, Pierron F, Avril S, Toussaint E (2006) The virtual fields method for extracting constitutive parameters from full-field measurements: a review. Strain 42(4):233–253

Pierron F, Grédiac M (2012) The Virtual Fields Method: extracting constitutive mechanical parameters from full-field deformation measurements, Springer New-York

Avril S, Bonnet M, Bretelle A, Grédiac M, Hild F, Ienny P, Latourte F, Lemosse D, Pagano S, Pagnacco E, Pierron F (2008) Overview of identification methods of mechanical parameters based on full-field measurements. Exp Mech 48(4):381–402

Kajberg J, Sundin K, Melin L, Ståhle P (2004) High strain-rate tensile testing and viscoplastic parameter identification using microscopic high-speed photography. Int J Plast 20(4-5):561–575

Grantham S, Siviour C, Proud W, Field J (2004) High-strain rate Brazilian testing of an explosive simulant using speckle metrology. Meas Sci Technol 15(5):1867–1870

Song B (2004) Dynamic stress equilibration in split Hopkinson pressure bar tests on soft materials. Exp Mech 44(3):300–312

Peirs J, Verleysen P, Van Paepegem W, Degrieck J (2011) Determining the stress-strain behaviour at large strains from high strain rate tensile and shear experiments. Int J Impact Eng 38:406–415

Kajberg J, Wikman B (2007) Viscoplastic parameter estimation by high strain-rate experiments and inverse modellingspeckle measurements and high-speed photography. Int J Solids Struct 44(1):145–164

Pierron F, Forquin P (2012) Ultra-high-speed full-field deformation measurements on concrete spalling specimens and stiffness identification with the virtual fields method. Strain 48(5):388–405

Pierron F, Zhu H, Siviour C (2014) Beyond Hopkinson’s bar. Phil Trans R Soc A 372(2023):1–24

Moulart R, Pierron F, Hallett S, Wisnom M (2011) Full-field strain measurement and identification of composites moduli at high strain rate with the virtual fields method. Exp Mech 51(4):509–536

Longana M (2014) Intermediate strain rate testing methodologies and full-field optical strain measurement techniques for composite materials characterisation, PhD thesis, University of Southampton

Hsiao H, Daniel I, Cordes R (1999) Strain rate effects on the transverse compressive and shear behavior of unidirectional composites. J Compos Mater 33(17):1620–1642

Shokrieh M, Omidi M (2009) Investigation of strain rate effects on in-plane shear properties of glass/epoxy composites. Compos Struct 91(1):95–102

Tochigi Y, Hanzawa K, Kato Y, Kuroda R, Mutoh H, Hirose R, Tominaga H, Takubo K, Kondo Y, Sugawa S (2013) A global-shutter CMOS image sensor with readout speed of 1-Tpixel/s burst and 780-Mpixel/s continuous. IEEE J Solid State Circuits 48(1):329–338

Kondo Y, Takubo K, Tominaga H, Hirose R, Tokuoka N, Kawaguchi Y, Takaie Y, Ozaki A (2013) Development of ”HyperVision HPV-X” high-speed video camera, Shimadzu Review SR3–003E

Surrel Y (1994) Moiré and grid methods: a signal processing approach. Photomechanics 2342:118–127

Piro J, Grédiac M (2004) Producing and transferring low-spatial-frequency grids for measuring displacement fields with moiré and grid methods. Exp Tech 28(4):23–26

Rossi M, Pierron F (2012) On the use of simulated experiments in designing tests for material characterization from full-field measurements. Int J Solids Struct 49(3-4):420–435

D’Amico M, Ferrigno G (1990) Technique for the evaluation of derivatives from noisy biomechanical displacement data using a model-based bandwidth-selection procedure. Med Biol Eng Comput 28(5):407–415

Wood G (1982) Data smoothing and differentiation procedures in biomechanics. Exerc Sport Sci Rev 10:308–362

Pierron F, Green B, Wisnom M (2007) Full-field assessment of the damage process of laminated composite open-hole tensile specimens. Part I: methodology. Compos A: Appl Sci Manuf 38(11):2307–2320

Avril S, Feissel P, Pierron F, Villon P (2008) Estimation of the strain field from full-field displacement noisy data. Comparing finite elements global least squares and polynomial diffuse approximation. Eur J Comput Mech 17(5-7):857–868

Avril S, Feissel P, Pierron F, Villon P (2010) Comparison of two approaches for differentiating full-field data in solid mechanics. Meas Sci Technol 21(1):015703

Haddad R, Akansu A (1991) A class of fast Gaussian binomial filters for speech and image processing. IEEE Trans Acoust Speech Signal Process 39:723–727

Digital filters: Gaussian smoothing. http://homepages.inf.ed.ac.uk/rbf/HIPR2/gsmooth.htm http://homepages.inf.ed.ac.uk/rbf/HIPR2/gsmooth.htm

Rossi M, Lava P, Pierron F, Debruyne D, Sasso M Effect of DIC spatial resolution, noise and interpolation error on identification results with the VFM, Strain In press

Aloui S, Othman R, Poitou A, Guégan P, El-Borgi S (2008) Non-parametric identification of the non-homogeneous stress in high strain-rate uni-axial experiments. Mech Res Commun 35(6):392–397

Othman R, Aloui S, Poitou A (2010) Identification of non-homogeneous stress fields in dynamic experiments with a non-parametric method. Polym Test 29(5):616–623

Toussaint E, Grédiac M, Pierron F (2006) The virtual fields method with piecewise virtual fields. Int J Mech Sci 48(3):256–264

Avril S, Grédiac M, Pierron F (2004) Sensitivity of the virtual fields method to noisy data. Comput Mech 34(6):439–452

Chowdhury I, Dasgupta S (2003) Computation of Rayleigh damping coefficients for large systems The Electronic Journal of Geotechnical Engineering 8 Bundle C

Arimitsu Y, Kazumi N, Toyomitsu S (1995) A study of Saint-Venant’s principle for composite materials by means of internal stress fields. J Appl Mech Trans ASME 62(1):53–58

Pierron F (1998) Saint-Venant effects in the Iosipescu specimen. J Compos Mater 22:1986–2015

Rossi M, Pierron F, Forquin P (2014) Assessment of the metrological performance of an in situ storage image sensor ultra-high speed camera for full-field deformation measurements. Meas Sci Technol 25(2):025401

Karp B, Durban D (2011) Saint-Venant’s principle in dynamics of structures. Appl Mech Rev 64(2):020801

Acknowledgments

This work is supported by China Scholarship Council (CSC) through the government grant of Haibin Zhu. Professor Pierron gratefully acknowledges support from the Royal Society and the Wolfson Foundation through a Royal Society Wolfson Research Merit Award. The authors would like to acknowledge Mr Brian Speyer from Speyer Photonics Ltd and Dr. Markus Ortlieb from Shimadzu Europa GmbH for lending the camera and helping out with the experiments. They would also like to thank Dr. Nicola Symonds and Dr. Liam Goodes from the nCATS group at the University of Southampton for their help with the impact rig.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

(AVI 10.4 MB)

(AVI 11.1 MB)

(AVI 10.5 MB)

(AVI 8.65 MB)

Rights and permissions

About this article

Cite this article

Zhu, H., Pierron, F. Exploration of Saint-Venant’s Principle in Inertial High Strain Rate Testing of Materials. Exp Mech 56, 3–23 (2016). https://doi.org/10.1007/s11340-015-0078-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-015-0078-1