Abstract

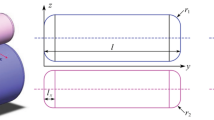

In mixed lubrication, wear is inevitable under the sliding condition due to the existence of the asperity contacts that bear partial normal load. This study proposes a numerical approach to predict the wear process of a cylinder sliding over a ring disk in mixed lubrication. Elastohydrodynamic lubrication of the rough contact, which is a line contact at the beginning of the sliding and gradually becomes a flatten cylinder/disk contact with the wear progress, is simulated with the three-dimensional finite element method. The elastic–plastic asperity contact model is adopted to calculate the asperity contact pressure. Based on the asperity contact load, the cylinder wear is computed with the Archard’s wear law. The wear process is simulated step by step, starting from an initial line contact configuration. In each calculation step, the cylinder geometry profile is updated, and the balance of the externally applied load with the elastohydrodynamic and the asperity contact loads is achieved. Variations of the cylinder geometry profile, the lubricant film thickness, and the friction coefficient are obtained for the whole rubbing process. Reasonable agreements on the changes of the wear scar width and the friction coefficient during the rubbing process between the simulation and the experiment results are obtained.

Similar content being viewed by others

Abbreviations

- b :

-

Semi-width of Hertz contact (m)

- b c :

-

Semi-width of the contact of a cylinder against a rough surface (m)

- b w :

-

Semi-width of cylinder wear scar (m)

- C :

-

Heat capacity (J kg−1 K−1)

- E 1,2 :

-

Young’s modulus (Pa)

- E′:

-

Effective modulus of elasticity (Pa)

- f :

-

Mixed lubrication friction coefficient

- f c :

-

Boundary condition friction coefficient

- H :

-

Material hardness (Pa)

- H T :

-

Total enthalpy (J Kg−1)

- h :

-

Nominal film thickness (m)

- h static :

-

Static enthalpy (J Kg−1)

- Δh :

-

Mesh motion (m)

- K :

-

Wear coefficient

- K m :

-

Maximum contact pressure factor

- k :

-

Turbulent kinetic energy (J)

- k T :

-

Thermal conductivity (W m−1 K−1)

- L :

-

Length of the cylinder wear scar (m)

- P k :

-

Production rate of turbulence

- p :

-

Hydrodynamic pressure (Pa)

- p c :

-

Asperity contact pressure (Pa)

- R :

-

Cylinder radius (m)

- R s :

-

Asperity radius (m)

- s :

-

Sliding distance (m)

- Δs :

-

Sliding distance increment (m)

- T :

-

Temperature (K)

- T 0 :

-

Ambient temperature (K)

- t :

-

Time (s)

- u :

-

Vector of velocity (m/s)

- u + :

-

Near-wall velocity (m/s)

- V :

-

Total wear volume (m3)

- ΔV :

-

Wear volume increment (m3)

- W :

-

Normal load (N)

- W c :

-

Asperity contact load (N)

- W f :

-

Hydrodynamic load (N)

- x, y, z :

-

Coordinate (m)

- y s :

-

Distance between the mean line of asperities and the mean line of surface heights (m)

- α :

-

Pressure viscosity index (m2 N−1)

- β :

-

Thermoviscosity index (oC−1)

- \(\dot{\gamma }\) :

-

Shear rate (s−1)

- η :

-

Dynamic viscosity of fluid (Pa.s)

- η 0 :

-

Fluid viscosity in the ambient conditions (Pa.s)

- η s :

-

Asperity density (m−2)

- η t :

-

Turbulence viscosity (Pa.s)

- ν 1,2 :

-

Poisson’s ratios

- ρ :

-

Fluid density (kg/m3)

- ρ 0 :

-

Fluid density in the ambient conditions (kg/m3)

- σ :

-

Equivalent surface roughness (m)

- σ 1,2 :

-

Standard deviation of surface heights (m)

- σ s :

-

Standard deviation of the asperity heights (m)

- τ :

-

Stress tensor (Pa)

- τ 0 :

-

Eyring stress (Pa)

- ϕ :

-

Distribution function of asperity heights

- ω :

-

Turbulent frequency (s−1)

- ω c :

-

Asperity contact interference (m)

- ω cr :

-

Critical interference (m)

References

Meng, H.C., Ludema, K.C.: Wear models and predictive equations: their form and content. Wear 181, 443–457 (1995). doi:10.1016/0043-1648(95)90158-2

Archard, J.F.: Contact and rubbing of flat surfaces. J. Appl. Phys. 24(8), 981–988 (1953). doi:10.1063/1.1721448

Põdra, P., Andersson, S.: Simulating sliding wear with finite element method. Tribol. Int. 32(2), 71–81 (1999). doi:10.1016/S0301-679X(99)00012-2

Põdra, P., Andersson, S.: Wear simulation with the Winkler surface model. Wear 207(1–2), 79–85 (1997). doi:10.1016/S0043-1648(96)07468-6

Olofsson, U., Andersson, S., Björklund, S.: Simulation of mild wear in boundary lubricated spherical roller thrust bearings. Wear 241(2), 180–185 (2000). doi:10.1016/S0043-1648(00)00373-2

Öqvist, M.: Numerical simulation of mild wear using updated geometry with different step size approaches. Wear 249(1–2), 6–11 (2001). doi:10.1016/S0043-1648(00)00548-2

Flodin, A., Andersson, S.: Simulation of mild wear in spur gears. Wear 207(1–2), 16–23 (1997). doi:10.1016/S0043-1648(96)07467-4

Flodin, A., Andersson, S.: A simplified model for wear prediction in helical gears. Wear 249(3–4), 285–292 (2001). doi:10.1016/S0043-1648(01)00556-7

Brauer, J., Andersson, S.: Simulation of wear in gears with flank interference: a mixed FE and analytical approach. Wear 254(11), 1216–1232 (2003). doi:10.1016/S0043-1648(03)00338-7

Põdra, P., Andersson, S.: Finite element analysis wear simulation of a conical spinning contact considering surface topography. Wear 224(1), 13–21 (1999). doi:10.1016/S0043-1648(98)00318-4

Hugnell, A.B.J., Bjorklund, S., Andersson, S.: Simulation of the mild wear in a cam-follower contact with follower rotation. Wear 199(2), 202–210 (1996). doi:10.1016/0043-1648(96)06920-7

Sawyer, W.G.: Wear predictions for a simple-cam including the coupled evolution of wear and load. Lubr. Eng. 57(9), 31–36 (2001)

Mukras, S., Kim, N.H., Sawyer, W.G., Jackson, D.B., Bergquist, L.W.: Numerical integration schemes and parallel computation for wear prediction using finite element method. Wear 266(7–8), 822–831 (2009). doi:10.1016/j.wear.2008.12.016

McColl, I.R., Ding, J., Leen, S.B.: Finite element simulation and experimental validation of fretting wear. Wear 256(11–12), 1114–1127 (2004). doi:10.1016/j.wear.2003.07.001

Hegadekatte, V., Huber, N., Kraft, O.: Finite element based simulation of dry sliding wear. Model. Simul. Mater. Sci. Eng. 13(1), 57–75 (2005). doi:10.1088/0965-0393/13/1/005

Benabdallah, H., Olender, D.: Finite element simulation of the wear of polyoxymethylene in pin-on-disc configuration. Wear 261(11–12), 1213–1224 (2006). doi:10.1016/j.wear.2006.03.040

Telliskivi, T.: Simulation of wear in a rolling-sliding contact by a semi-Winkler model and the Archard’s wear law. Wear 256(7–8), 817–831 (2004). doi:10.1016/S0043-1648(03)00524-6

Sfantos, G.K., Aliabadi, M.H.: Wear simulation using an incremental sliding boundary element method. Wear 260(9–10), 1119–1128 (2006). doi:10.1016/j.wear.2005.07.020

Zhu, D., Martini, A., Wang, W., Hu, Y., Lisowsky, B., Wang, Q.J.: Simulation of sliding wear in mixed lubrication. Tribol. Trans. 129(3), 544–552 (2007). doi:10.1115/1.2736439

Bowden, F.P., Leben, L.: The friction of lubricated metals. Philos. Trans. R. Soc. Lond. A 239(799), 1–27 (1940). doi:10.1098/rsta.1940.0007

Adamson, A.W.: Physical chemistry of surfaces. Interscience, New York (1976)

Greenwood, J.A., Williamson, J.B.P.: Contact of nominally flat surfaces. Proc. R. Soc. Lond. Ser. A. 295(1442), 300–319 (1966). doi:10.1098/rspa.1966.0242

Chang, W.R., Etsion, I., Bogy, D.B.: An elastic-plastic model for the contact of rough surfaces. J. Tribol. 109(2), 257–263 (1987). doi:10.1115/1.3261348

Cohen, D., Kligerman, Y., Etsion, I.: A model for contact and static friction of nominally flat rough surfaces under full stick contact condition. J. Tribol. 130(3), 031401-1-9 (2008). doi:10.1115/1.2908925

Tabor, D.: The hardness of metals. Oxford University Press, Oxford (1951)

Zhu, D., Cheng, H.S.: Effect of surface roughness on the point contact EHL. J. Tribol. 110(1), 32–37 (1988). doi:10.1115/1.3261571

Jiang, X., Cheng, H.S., Hua, D.Y.: A theoretical analysis of mixed lubrication by macro micro approach: part I—results in a gear surface contact. Tribol. Trans. 43(4), 689–699 (2000). doi:10.1080/10402000008982398

Lo, C.C.: Elastic contact of rough cylinders. Int. J. Mech. Sci. 11(1), 105–115 (1969). doi:10.1016/0020-7403(69)90083-6

CFX 13.0. Users Guide. ANSYS Inc. (2013)

Roelands, C. J. A.: Correlational aspects of the viscosity–temperature–pressure relationship of lubricating oils. Ph.D. thesis, Delft University of Technology, Netherlands (1966)

Dowson, D., Higginson, G.R.: Elasto-hydrodynamic lubrication. Pergamon Press, Oxford (1977)

Wen, S.Z., Huang, P.: Principles of tribology. Tsinghua University Press, Beijing (2008)

Kim, N.H., Won, D., Burris, D., Holtkamp, B., Gessel, G.R., Swanson, P., Sawyer, W.G.: Finite element analysis and experiments of metal/metal wear in oscillatory contacts. Wear 258(11–12), 1787–1793 (2005). doi:10.1016/j.wear.2004.12.014

Jackson, R.L., Green, I.: The behavior of thrust washer bearings considering mixed lubrication and asperity contact. Tribol. Trans. 49(2), 233–247 (2006). doi:10.1080/05698190600614841

Ruan, B., Salant, R.F., Green, I.: A mixed lubrication model of liquid/gas mechanical face seals. Tribol. Trans. 40(4), 647–657 (1997). doi:10.1080/10402009708983705

Hu, Y.Z., Li, N., Tønder, K.: A dynamic system model for lubricated sliding wear and running-in. J. Tribol. 113(3), 499–505 (1991). doi:10.1115/1.2920651

Wang, W., Wong, P.L., Guo, F.: Application of partial elastohydrodynamic lubrication analysis in dynamic wear study for running-in. Wear 257(7), 823–832 (2004). doi:10.1016/j.wear.2004.05.003

Akbarzadeh, S., Khonsari, M.M.: On the prediction of running-in behavior in mixed -lubrication line contact. J. Tribol. 132(3), 032102-1-11 (2010). doi:10.1115/1.4001622

Qiu, Y., Khonsari, M.M.: Investigation of tribological behaviors of annular rings with spiral groove. Tribol. Int. 44(12), 1610–1619 (2011). doi:10.1016/j.triboint.2011.05.008

Larsson, R.: Modelling the effect of surface roughness on lubrication in all regimes. Tribol. Int. 42(4), 512–516 (2009). doi:10.1016/j.triboint.2008.07.007

Wang, W., Wong, P.L., Zhang, Z.: Experimental study of the real time change in surface roughness during running-in for PEHL contacts. Wear 244(1), 140–146 (2000). doi:10.1016/S0043-1648(00)00448-8

Johnson, K., Greenwood, J.A., Poon, S.Y.: Simple theory of asperity contact in elastohydrodynamic lubrication. Wear 19(1), 91–108 (1972). doi:10.1016/0043-1648(72)90445-0

Gelinck, E.R.M., Schipper, D.J.: Deformation of rough line contacts. J. Tribol. 121(3), 449–454 (1999). doi:10.1115/1.2834088

Masjedi, M., Khonsari, M.M.: Film thickness and asperity load formulas for line-contact elastohydrodynamic lubrication with provision for surface roughness. J. Tribol. 134(1), 011503-1-10 (2012). doi:10.1115/1.4005514

Kovalchenko, A., Ajayi, O., Erdemir, A., Fenske, G.: Friction and wear behavior of laser textured surface under lubricated initial point contact. Wear 271(9–10), 1719–1725 (2011). doi:10.1016/j.wear.2010.12.049

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hao, L., Meng, Y. Numerical Prediction of Wear Process of an Initial Line Contact in Mixed Lubrication Conditions. Tribol Lett 60, 31 (2015). https://doi.org/10.1007/s11249-015-0609-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0609-z