Abstract

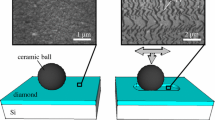

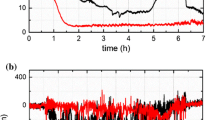

The mechanical behaviour of materials at nanometre dimensions has been a major recent topic of research. In this study, the wear properties of a ~60-nm thin foil made of the ductile fcc phase of a CoCrMo alloy were examined using in situ sliding test in a transmission electron microscope by sliding a silicon AFM tip on the fcc matrix under an applied normal load of 416–1,279 nN. The material near the surface was deformed plastically, forming dislocations and dislocation cells at the surface. The wear process was found to be strongly dependent on extrinsic factors, namely the attack angle between the tip and the CoCrMo surface. At an attack angle of 64°, the surface was removed by continuous fractures 40–73 nm below the surface. At a lower attack angle of 24°, the abrasive wear switched to ploughing.

Similar content being viewed by others

References

Dowson, D.: History of tribology. Professional Engineering Publishers, London (1998)

Johnson, K.L.: Contact mechanics. Cambridge University Press, Cambridge (1985)

Hutchings, I.M.: Tribology: friction and wear of engineering materials. Edward Arnold, London (1992)

Williams, J.A.: Engineering tribology. Oxford University Press, Oxford (1994)

Bowden, F.P., Tabor, D., Gane, N., Willis, R.F.: Solid surfaces under static and sliding contact-some recent work on microdeformation and chemical reactivity. Z. Phys. Chem-Leipzig 244, 129 (1970)

Gane, N., Bowden, F.P.: Microdeformation of solids. J. Appl. Phys. 39, 1432 (1968)

Bowden, F.P., Tabor, D.: The friction and lubrication of solids. Clarendon Press, Oxford (1950)

Bowden, F.P., Moore, A.J.W., Tabor, D.: The ploughing and adhesion of sliding metals. J. Appl. Phys. 80, 80–91 (1942)

Bhushan, B.: Contact mechanics of rough surfaces in tribology: multiple asperity contact. Tribol. Lett. 4, 1–35 (1998). doi:10.1023/A:1019186601445

Bhushan, B.: Handbook of micro/nanotribology. CRC Press, Boca Raton (1995)

Bhushan, B., Majumdar, A.: Fractal theory of the interfacial temperature distribution in the slow sliding regime. 1. Elastic contact and heat-transfer analysis—discussion. J. Tribol. T. ASME 116, 822 (1994). doi:10.1115/1.2927339

Rigney, D.A.: Comments on the sliding of wear of metals. Tribol. Int. 30, 361–367 (1997)

Marks, L.D., Warren, O.L., Minor, A.M., Merkle, A.P.: Tribology in full view. MRS Bull. 33, 1168–1173 (2008)

Gotsmann, B., Lantz, M. A.: Atomistic wear in a single asperity sliding contact. Phys. Rev. Lett. 101, 125501 (2008)

Bhaskaran, H., et al.: Ultralow nanoscale wear through atom-by-atom attrition in silicon-containing diamond-like carbon. Nat. Nanotechnol. 5, 181–185 (2010)

Jacobs, T.D.B., Carpick, R.W.: Nanoscale wear as a stress-assisted chemical reaction. Nat. Nanotechnol. 8, 108–112 (2013)

Gnecco, E., Bennewitz, R., Meyer, E.: Abrasive wear on the atomic scale. Phys. Rev. Lett. 88, 215501 (2002)

Szlufarska, I., Chandross, M., Carpick, R.W.: Recent advances in single-asperity nanotribology. J. Phys. D Appl. Phys. 41, 123001–123039 (2008)

Bates, T.R., Ludema, K.C., Brainard, W.A.: Rheological mechanism of penetrative wear. Wear 30, 365–375 (1974). doi:10.1016/0043-1648(74)90150-1

Kato, K.: Micromechanisms of wear—wear modes. Wear 153, 277–295 (1992). doi:10.1016/0043-1648(92)90274-C

Hokkirigawa, K., Kato, K.: An experimental and theoretical investigation of plowing, cutting and wedge formation during abrasive wear. Tribol. Int. 21, 51–57 (1988). doi:10.1016/0301-679x(88)90128-4

Kato, K., Kayaba, T., Endo, Y., Hokkirigawa, K.: Three dimensional shape effect on abrasive wear. J. Tribol. 108, 346–349 (1986)

Liao, Y., EswaraMoorthy, S.K., Marks, L.D.: Direct observation of tribological recrystallization. Phil. Mag. Lett. 90, 219–223 (2010). doi:10.1080/09500830903571384

Merkle, A.P., Marks, L.D.: Liquid-like tribology of gold studied by in situ TEM. Wear 265, 1864–1869 (2008). doi:10.1016/j.wear.2008.04.032

Luan, B.Q., Robbins, M.O.: The breakdown of continuum models for mechanical contacts. Nature 435, 929–932 (2005). doi:10.1038/Nature03700

Jacobs, J.J., et al.: Metal-on-metal bearing surfaces. J. Am. Acad. Orthop. Sur. 17, 69–76 (2009)

Liao, Y., et al.: New insights into hard phases of CoCrMo metal-on-metal hip replacements. J. Mech. Behav. Biomed. 12, 39–49 (2012)

Stemmer, P. et al.: Microstructure of retrievals made from standard cast HC-CoCrMo alloys. ASTM-STP, (2012, in print)

Pourzal, R., et al.: Subsurface changes of a MoM hip implant below different contact zones. J. Mech. Behav. Biomed. 2, 186–191 (2009). doi:10.1016/j.jmbbm.2008.08.002

Clemow, A.J.T., Daniell, B.L.: Solution treatment behavior of Co-Cr-Mo alloy. J. Biomed. Mater. Res. 13, 265–279 (1979)

Liao, Y., Marks, L. D.: Direct observation of layer-by-layer wear. (2014, submitted)

Dillamor, I.L.: The stacking fault energy dependence of the mechanisms of deformation in fcc metals. Metall. Trans. 1, 2463–2470 (1970)

Rajan, K., Vandersande, J.B.: Room-temperature strengthening mechanisms in a Co-Cr-Mo-C alloy. J. Mater. Sci. 17, 769–778 (1982). doi:10.1007/Bf00540374

Uchic, M.D., Dimiduk, D.M., Florando, J.N., Nix, W.D.: Sample dimensions influence strength and crystal plasticity. Science 305, 986–989 (2004)

Chisholm, C., et al.: Dislocation starvation and exhaustion hardening in Mo alloy nanofibers. Acta Mater. 60, 2258–2264 (2012). doi:10.1016/j.actamat.2011.12.027

Shan, Z.W., Mishra, R.K., Asif, S.A.S., Warren, O.L., Minor, A.M.: Mechanical annealing and source-limited deformation in submicrometre-diameter Ni crystals. Nat. Mater. 7, 115–119 (2007)

Minor, A.M., et al.: A new view of the onset of plasticity during the nanoindentation of aluminium. Nat. Mater. 5, 697–702 (2006). doi:10.1038/Nmat1714

Buscher, R., et al.: Subsurface microstructure of metal-on-metal hip joints and its relationship to wear particle generation. J. Biomed. Mater. Res. B 72B, 206–214 (2005). doi:10.1002/Jbm.B.30132

Buscher, R., Fischer, A.: The pathways of dynamic recrystallization in all-metal hip joints. Wear 259, 887–897 (2005). doi:10.1016/j.wear.2005.02.036

Bryant, M., et al.: Characterisation of the surface topography, tomography and chemistry of fretting corrosion product found on retrieved polished femoral stems. J. Mech. Behav. Biomed. 32, 321–334 (2014)

Zhao, X.Z., Bhushan, B.: Material removal mechanisms of single-crystal silicon on nanoscale and at ultralow loads. Wear 223, 66–78 (1998). doi:10.1016/S0043-1648(98)00302-0

Mishra, M., Szlufarska, I.: Dislocation controlled wear in single crystal silicon carbide. J. Mater. Sci. 48, 1593–1603 (2013). doi:10.1007/s10853-012-6916-y

Challen, J.M., Oxley, P.L.B.: Explanation of the different regimes of friction and wear using asperity deformation models. Wear 53, 229–243 (1979). doi:10.1016/0043-1648(79)90080-2

Hearle, A.D., Johnson, K.L.: Mode-II stress intensity factors for a crack parallel to the surface of an elastic half-space subjected to a moving point load. J. Mech. Phys. Solids 33, 61 (1985). doi:10.1016/0022-5096(85)90022-5

Lawn, B.R., Swain, M.V.: Microfracture beneath point indentations in brittle solids. J. Mater. Sci. 10, 113–122 (1975). doi:10.1007/Bf00541038

Lawn, B.R., Fuller, E.R.: Equilibrium penny-like cracks in indentation fracture. J. Mater. Sci. 10, 2016–2024 (1975). doi:10.1007/Bf00557479

Suh, N.P.: Delamination theory of wear. Wear 25, 111–124 (1973)

Varenberg, M.: Towards a unified classification of wear. Friction 1, 333–340 (2013)

Acknowledgments

This work was funded by the NSF under the Grant Number CMMI-1030703. The Electron Microscopy Center of Argonne National Laboratory is acknowledged for the use of their facilities. Ms. Gwendolyn Reid is acknowledged for proof reading the manuscript.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (MPG 1104 kb)

Supplementary material 2 (MPG 1175 kb)

Rights and permissions

About this article

Cite this article

Liao, Y., Hoffman, E. & Marks, L.D. Nanoscale Abrasive Wear of CoCrMo in In Situ TEM Sliding. Tribol Lett 57, 28 (2015). https://doi.org/10.1007/s11249-015-0471-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0471-z