Abstract

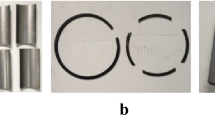

Wear particle analysis can be developed as an effective method for assessment of the running conditions of concaved cylinder liners. The aim of this study was to numerically characterize the topographical features of wear particles generated from different surface textured cylinder liners and to investigate their changes with alternations in both rotational speeds and surface textures. To achieve this goal, cylinder liners with three different surface textures were prepared and tested in four different speeds. In addition to an untreated surface, concave cylinder liner surfaces with two different diameters (1 and 2 mm) and two different depths (200 and 300 μm) were investigated. Wear particles were extracted from the lubrication oil; three-dimensional images of the wear debris were acquired using laser confocal microscopy; and their topographical features were analyzed quantitatively. This study has revealed that running-in conditions and stable state can be detected using wear debris analysis techniques at a micrometer scale. It has also been discovered that concave B cylinder liner with a depth–diameter ratio of 0.1 always generated wear particles different to those from the other two cylinder liners on each rotational speed. It is believed that the quantitative surface topography characterization results obtained in this study provide a practical base for developing a new, non-intrusive tool for monitoring the operation conditions of cylinder liner–piston rings in diesel engines.

Similar content being viewed by others

References

Grabon, W., Pawlus, P., Sep, J.: Tribological characteristics of one-process and two-process cylinder liner honed surfaces under reciprocating sliding conditions. Tribol. Int. 43, 1882–1892 (2010)

Guo, Z., Yuan, C., Liu, P., Peng, Z., Yan, X.: Study on influence of cylinder liner surface texture on lubrication performance for cylinder liner–piston ring components. Tribol. Lett. 51, 9–23 (2013)

Etsion, I., Sher, E.: Improving fuel efficiency with laser surface textured piston rings. Tribol. Int. 42, 542–547 (2009)

Zhou, Y., Zhu, H., Tang, W., Ma, C., Zhang, W.: Development of the theoretical model for the optimal design of surface texturing on cylinder liner. Tribol. Int. 52, 1–6 (2012)

Krupka, I., Poliscuk, R., Hartl, M.: Behavior of thin viscous boundary films in lubricated contacts between micro-textured surfaces. Tribol. Int. 42, 535–541 (2009)

Borghi, A., Gualtieri, E., Marchetto, D., Moretti, L., Valeri, S.: Tribological effects of surface texturing on nitriding steel for high-performance engine applications. Wear 265, 1046–1051 (2008)

Etsion, I.: State of the art in laser surface texturing. Trans. ASME J. Tribol. 127, 248–253 (2003)

Mourier, L., Mazuyer, D., Lubrecht, A., Donnet, C.: Transient increase of film thickness in micro-textured EHL contacts. Tribol. Int. 39, 1745–1756 (2006)

Etsion, I.: Improving tribological performance of mechanical components by laser surface texturing. Tribol. Lett. 17, 733–737 (2004)

Ronen, A., Etsion, I., Kligerman, Y.: Friction-reducing surface-texturing in reciprocating automotive components. Tribol. Trans. 44, 359–366 (2001)

Michalski, J., Wos, P.: The effect of cylinder liner surface topography on abrasive wear of piston-cylinder assembly in combustion engine. Wear 271, 582–589 (2011)

Scaraggi, M., Mezzapesa, F., Carbone, G., Ancona, A., Tricarico, L.: Friction properties of lubricated laser-micro textured-surfaces: an experimental study from boundary- to hydrodynamic-lubrication. Tribol. Lett. 49, 117–125 (2013)

Fu, Y., Ye, Y., Zhang, Y., Cai, L.: The technology of laser honing applied in distinctively improving the lubrication of frictional units. Key Eng. Mater. 202, 265–270 (2001)

Wos, P., Michalski, J.: Effect of initial cylinder liner honing surface roughness on aircraft piston engine performances. Tribol. Lett. 41, 555–567 (2011)

Weidner, A., Seewig, J., Reithmeier, E.: 3D roughness evaluation of cylinder liner surfaces based on structure-oriented parameters. Meas. Sci. Technol. 17, 477–482 (2006)

Wu, J., Peng, Z.: Investigation of the geometries and surface topographies of UHMWPE wear particles. Tribol. Int. 66, 208–218 (2013)

Tian, Y., Wang, J., Peng, Z., Jiang, X.: A new approach to numerical characterisation of wear particle surfaces in three-dimensions for wear study. Wear 282–283, 59–68 (2012)

Peng, Z., Kirk, T.: Computer image analysis of wear particles in three-dimensions for machine condition monitoring. Wear 223, 157–166 (1998)

Besong, A., Tipper, J., Ingham, E., Stone, M., Wrobewski, B., Fisher, J.: Quantitative comparison of wear debris from UHMWPE that has and has not been sterilised by gamma irradiation. J. Bone. Joint. Surg. Br. 80, 340–344 (1998)

Roylance, B., Williams, J., Dwyer-Joyce, R.: Wear debris and associated wear phenomena-fundamental research and practice. Part I. Mech. Eng. J. Eng. 214, 79–105 (2000)

Wu, T., Peng, Y., Wu, H., Zhang, X., Wang, J.: Full-life dynamic identification of wear state based on on-line wear debris image features. Mech. Syst. Signal. Process. 42, 404–414 (2014)

Yuan, C., Yan, X., Jin, Z., Tipper, L.: Numerical surface characterization of wear debris from artificial joints using atomic force microscopy. Chin. Sci. Bull. 54, 4583–4588 (2010)

Yuan, C.Q., Peng, Z., Zhou, X., Yan, X.: The surface roughness evolutions of wear particles and wear components under lubricated rolling wear condition. Wear 259, 512–518 (2005)

Wu, T., Wang, J., Peng, Y., Zhang, Y.: Description of wear debris from on-line ferrograph images by their statistical color. Tribol. Trans. 55, 606–614 (2012)

Yuan, C., Li, J., Yan, X., Peng, Z.: The use of the fractal description to characterize engineering surfaces and wear particles. Wear 255, 315–326 (2012)

Li, Z., Yan, X., Guo, Z., Liu, P., Yuan, C., Peng, Z.: A new intelligent fusion method of multi-dimensional sensors and its application to tribo-system fault diagnosis of marine diesel engines. Tribol. Lett. 47, 1–15 (2012)

Scaraggi, M., Carbone, G., Persson, B., Dini, D.: Lubrication in soft rough contacts: a novel homogenized approach. Part I. Theory. Soft. Mater. 7, 10395–10406 (2011)

Peng, Z.: Osteoarthritis diagnosis using wear particle analysis technique: investigation of correlation between particle and cartilage surface in walking process. Wear 262, 630–640 (2007)

ISO 25178-2: Geometrical product specifications (GPS)—Surface texture: Areal—Part 2: Terms, definitions and surface texture parameters (2012)

Peng, Z., Wang, M.: Three dimensional surface characterization of human cartilages at a micron and nanometre scale. Wear 301, 210–217 (2013)

Munz, M.: Microstructure and roughness of photopolymerized poly (ethylene glycol) diacrylate hydrogel as measured by atomic force microscopy in amplitude and frequency modulation mode. Appl. Surf. Sci. 279, 300–309 (2013)

Sudipto, R., Chowdhury, S.: Experimental investigation into the effect of 3D surface roughness parameters on flash temperature. Ind. Lubr. Tribol. 63, 90–102 (2011)

Mandelbrot, B.: The fractal geometry of nature. W.H. Freeman, New York (1983)

Mezghani, S., Demirci, I., Zahouani, H., Mansori, M.: The effect of groove texture patterns on piston-ring pack friction. Precis. Eng. 36, 210–217 (2012)

Acknowledgments

The authors would like to express their sincere gratitude to the Program for New Century Excellent Talents in University (NCET-12-0910), the Fok Ying-Tong Education Foundation for Young Teachers in the Higher Education Institutions of China (No. 131051) and the Program of Introducing Talents of Discipline to Universities (No. B08031).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, Z., Yuan, C., Yan, X. et al. 3D Surface Characterizations of Wear Particles Generated from Lubricated Regular Concave Cylinder Liners. Tribol Lett 55, 131–142 (2014). https://doi.org/10.1007/s11249-014-0340-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-014-0340-1