Abstract

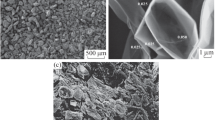

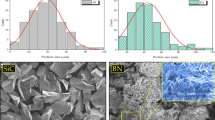

The influence of graphite content on the dry sliding wear characteristics of Al6061/Gr composites along with Al6061/30SiC/Gr hybrid composites has been assessed using a pin-on-disc wear test. The composites with different volume fraction of graphite particles up to 13% were processed by in situ powder metallurgy (IPM) technique. The porosity and hardness of the resultant composites were also examined. It was found that an increase in the graphite content reduced the porosity, hardness, and friction coefficient of both types of composites. The hybrid composites were more porous and exhibited higher hardness and lower coefficient of friction at identical graphite contents. The increased graphite content in the range of 0–13 vol.% resulted in increased wear rate of Al/Gr composites. The Al/30SiC composite exhibited a lower wear rate as compared with the base alloy and graphite addition up to 9 vol.% improved the wear resistance of these hybrid composites. However, more graphite particles addition resulted in increased wear rate. SEM micrographs revealed that the wear mechanism was changed from mostly adhesive in the base alloy sample (Al/0Gr) to the prominently abrasive and delamination wear for Al/Gr and Al/SiC/Gr/composites.

Similar content being viewed by others

References

Kumar, S., Balasubramanian, V.: Effect of reinforcement size and volume fraction on the abrasive wear behavior of AA7075Al/SiCp P/M composites—a statistical analysis. Tribol. Int. 43, 414–422 (2010)

TianChi, W., TongXiang, F., Di, Z., GuoDing, Z.: The fabrication and wear properties of C/Al and (C + SiC)/Al composites based on wood template. Mater. Lett. 60, 2695–2699 (2006)

Jun, D., Yao-hui, L., Si-rong, Y., Wen-fang, L.: Dry sliding friction and wear properties of Al2O3 and carbon short fibres reinforced Al–12Si alloy hybrid composites. Wear 257, 930–940 (2004)

Onat, A.: Mechanical and dry sliding wear properties of silicon carbide particulate reinforced aluminium–copper alloy matrix composites produced by direct squeeze casting method. J. Alloys Compd. 489, 119–124 (2010)

Unlu, B.S.: Investigation of tribological and mechanical properties Al2O3–SiC reinforced Al composites manufactured by casting or P/M method. Mater. Des. 29, 2002–2008 (2008)

Rohatgi, P.K., Schultz, B.F., Daoud, A., Zhang, W.W.: Tribological performance of A206 aluminum alloy containing silica sand particles. Tribol. Int. 43, 455–466 (2010)

Rodriguez, J., Poza, P., Garrido, M.A., Rico, A.: Dry sliding wear behaviour of aluminium–lithium alloys reinforced with SiC particles. Wear 262, 292–300 (2007)

Chang, H., Binner, J., Higginson, R.: Dry sliding wear behaviour of Al(Mg)/Al2O3 interpenetrating composites produced by a pressureless infiltration technique. Wear 268, 166–171 (2010)

Jung-moo, L., Suk-bong, K., Jianmin, H.: Dry sliding wear of MAO-coated A356/20 vol.% SiCp composites in the temperature range 25–180°C. Wear 264, 75–85 (2008)

Rao, R.N., Das, S., Mondal, D.P., Dixit, G.: Dry sliding wear behaviour of cast high strength aluminium alloy (Al–Zn–Mg) and hard particle composites. Wear 267, 1688–1695 (2009)

Bai, M., Xue, Q.: Investigation of wear mechanism of SiC particulate-reinforced Al–20Si–3Cu–1 Mg aluminium matrix composites under dry sliding and water lubrication. Tribol. Int. 30, 261–269 (1997)

Suresha, S., Sridhara, B.K.: Wear characteristics of hybrid aluminium matrix composites reinforced with graphite and silicon carbide particulates. Compos. Sci. Technol. 70, 1652–1659 (2010)

Basavarajappa, S., Chandramohan, G., Mukund, K., Ashwin, M., Prabu, M.: Dry sliding wear behavior of Al2219/SiCp-Gr hybrid metal matrix composites. J. Mater. Eng. Perform. 15, 668–674 (2006)

Rao, R.N., Das, S., Mondal, D.P., Dixit, G.: Effect of heat treatment on the sliding wear behaviour of aluminium alloy (Al–Zn–Mg) hard particle composite. Tribol. Int. 43, 330–339 (2010)

Rao, R.N., Das, S.: Effect of matrix alloy and influence of SiC particle on the sliding wear characteristics of aluminium alloy composites. Mater. Des. 31, 1200–1207 (2010)

Leng, J., Jiang, L., Wu, G., Tian, S., Chen, G.: Effect of graphite particle reinforcement on dry sliding wear of SiC/Gr/Al composites. Rare Met. Mater. Eng. 38, 1894–1898 (2009)

Hassan, A.M., Alrashdan, A., Hayajneh, M.T., Mayyas, A.T.: Wear behavior of Al–Mg–Cu-based composites containing SiC particles. Tribol. Int. 42, 1230–1238 (2009)

Gui, M., Kang, S.B.: Dry sliding wear behavior of plasma-sprayed aluminum hybrid composite coatings. Metall. Mater. Trans. A 32A, 2383–2392 (2001)

Tang, F., Wu, X., Ge, S., Ye, J., Zhu, H., Hagiwara, M., Schoenung, J.M.: Dry sliding friction and wear properties of B4C particulate-reinforced Al-5083 matrix composites. Wear 264, 555–561 (2008)

Mondal, A.K., Kumar, S.: Dry sliding wear behaviour of magnesium alloy based hybrid composites in the longitudinal direction. Wear 267, 458–466 (2009)

Zhan, Y., Zhang, G.: Graphite and SiC hybrid particles reinforced copper composite and its tribological characteristic. J. Mater. Sci. Lett. 22, 1087–1089 (2003)

Ma, W., Lu, J.: Effect of sliding speed on surface modification and tribological behaviour of copper–graphite composite. Tribol. Lett. 41, 363–370 (2011)

Jha, A.K., Prasad, S.V., Upadhyaya, G.S.: Dry sliding wear of sintered 6061 aluminium alloy–graphite particle composites. Tribol. Int. 22, 321–327 (1989)

Ramesh, C.S., NoorAhmed, R., Mujeebu, M.A., Abdullah, M.Z.: Development and performance analysis of novel cast copper–SiC–Gr hybrid composites. Mater. Des. 30, 1957–1965 (2009)

Chu, H.Y., Lin, J.F.: Experimental analysis of the tribological behavior of electroless nickel-coated graphite particles in aluminum matrix composites under reciprocating motion. Wear 239, 126–142 (2000)

TedGuo, M.L., Tsao, C.Y.A.: Tribological behavior of aluminum/SiC/nickel-coated graphite hybrid composites. Mater. Sci. Eng. A 333, 134–145 (2002)

Akhlaghi, F., Pelaseyyed, S.A.: Characterization of aluminum/graphite particulate composites synthesized using a novel method termed “in situ powder metallurgy”. Mater. Sci. Eng. A 385, 258–266 (2004)

Akhlaghi, F., ZareBidaki, A.: Influence of graphite content on the dry sliding and oil impregnated sliding wear behavior of Al 2024–graphite composites produced by in situ powder metallurgy method. Wear 266, 37–45 (2009)

Zhao, H., Liu, L., Hu, W., Shen, B.: Friction and wear behavior of Ni–graphite composites prepared by electroforming. Mater. Des. 28, 1374–1378 (2007)

Zhan, Y., Zhang, G.: The role of graphite particles in the high-temperature wear of copper hybrid composites against steel. Mater. Des. 27, 79–84 (2006)

Akhlaghi, F., Esfandiari, H.: Solid-assisted melt disintegration (SAMD), a novel technique for metal powder production. Mater. Sci. Eng. A 452–453, 70–77 (2007)

Akhlaghi, F., Esfandiari, H.: Aluminium powder particles produced by SAMD technique: typical characteristics and correlations between processing conditions and powder size. Mater. Sci. Technol. 23, 646–652 (2007)

Akhlaghi, F., DelshadKhatibi, P.: Effect of silicon content on size distribution and morphology of Al–Si powder particles produced by solid assisted melt disintegration (SAMD) method. Powder Metall. 54(2), 153–159 (2011)

Mahdavi, S., Akhlaghi, F.: Effect of SiC content on the processing, compaction behavior, and properties of Al6061/SiC/Gr hybrid composites. J. Mater. Sci. 46, 1502–1511 (2011)

Mei-juan, Z., Xiao-hong, Y., Yong-bing, L., Zhan-yi, C., Li-ren, C., Ya-li, P.: Effect of graphite content on wear property of graphite/Al2O3/Mg-9Al-1Zn-0.8Ce composites. Trans. Nonferrous Met. Soc. China 20, 207–211 (2010)

Qing-ju, Q.I.: Evaluation of sliding wear behavior of graphite particle-containing magnesium alloy composites. Trans. Nonferrous Met. Soc. China 16, 1135–1140 (2006)

Rajkumar, K., Aravindan, S.: Tribological performance of microwave sintered copper–TiC–graphite hybrid composites. Tribol. Int. 44, 347–358 (2011)

Goto, H., Uchijo, K.: Wear mechanism of Al–Si alloy impregnated graphite composite under dry sliding. Wear 259, 613–619 (2005)

Liu, Y.B., Lim, S.C., Rayb, S., Rohatgi, P.K.: Friction and wear of aluminium–graphite composites: the smearing process of graphite during sliding. Wear 159, 201–205 (1992)

Ames, W., Alpas, A.T.: Wear mechanisms in hybrid composites of graphite-20 pct SiC in A356 aluminum alloy (Al-7 pct Si-0.3 pct Mg). Metall. Mater. Trans. A 26A, 85–98 (1995)

Song, J.I., Han, K.S.: Effect of volume fraction of carbon fibers on wear behavior of Al/Al2O3/C hybrid metal matrix composites. Compos. Struct. 39(3–4), 309–318 (1997)

Saidatulakmar, S., ShamsulBahrain, J., Zuhailawati, H., ZainalArifin, A.: The effect of Al2O3 amount on the microstructure and properties of Fe–Cr matrix composites. Metall. Mater. Trans. A 41A, 3452–3457 (2010)

Savaskan, T., Bican, O.: Dry sliding friction and wear properties of Al–25Zn–3Cu–(0–5)Si alloys in the as-cast and heat-treated conditions. Tribol. Lett. 40, 327–336 (2010)

Jahanmir, S., Suh, N.P., Abrahamson, E.P.: The delamination theory of wear and the wear of a composite surface. Wear 32, 33–49 (1975)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mahdavi, S., Akhlaghi, F. Effect of the Graphite Content on the Tribological Behavior of Al/Gr and Al/30SiC/Gr Composites Processed by In Situ Powder Metallurgy (IPM) Method. Tribol Lett 44, 1–12 (2011). https://doi.org/10.1007/s11249-011-9818-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-011-9818-2