Abstract

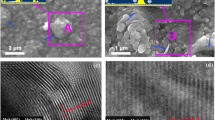

MoS2–Sb2O3–C composite films exhibit adaptive behavior, where surface chemistry changes with environment to maintain the good friction and wear characteristics. In previous work on nanocomposite coatings grown by PVD, this type of material was called a “chameleon” coating. Coatings used in this report were applied by burnishing mixed powders of MoS2, Sb2O3 and graphite. The solid lubricant MoS2 and graphite were selected to lubricate over a wide and complementary range including vacuum, dry air and humid air. Sb2O3 was used as a dopant because it acts synergistically with MoS2, improving friction and wear properties. The MoS2–Sb2O3–C composite films showed lower friction and longer wear life than either single component MoS2 or C film in humid air. Very or even super low friction and long wear-life were observed in dry nitrogen and vacuum. The excellent tribological performance was verified and repeated in cycles between humid air and dry nitrogen. The formation of tribo-films at rubbing contacts was studied to identify the lubricating chemistry and microstructure, which varied with environmental conditions. Micro-Raman spectroscopy and Auger electron spectroscopy (AES) were used to determine surface chemistry, while scanning electron microscopy and transmission electron microscopy were used for microstructural analysis. The tribological improvement and lubrication mechanism of MoS2–Sb2O3–C composite films were caused by enrichment of the active lubricant at the contact surface, alignment of the crystal orientation of the lubricant grains, and enrichment of the non lubricant materials below the surface. Sb2O3, which is not lubricious, was covered by the active lubricants (MoS2 – dry, C – humid air). Clearly, the dynamics of friction during environmental cycling cleaned some Sb2O3 particles of one lubricant and coated it with the active lubricant for the specific environment. Mechanisms of lubrication and the role of the different materials will be discussed.

Similar content being viewed by others

References

Haltner A.J., Oliver C.S.. (1960) Nature 188:308

Calhoun S.F., Meade F.S., Murphy G.P., Young R.L.. (1965) Lubric. Eng. 21:97

Pardee R.P. (1972) ASLE Trans. 15:130

Lavik M.T., Hubbell R.D., McConnell B.D.. (1975) Lubric. Eng. 31:20

Centers P.W., (1987) Tribol. Trans. 31/32:149

Centers P.W.. (1988) Wear 122:97

Klenke C.J.. (1990) Trib. Intl. 23:23

Zabinski J.S., Donley M.S., Dyhouse V.J., McDevitt N.T.. (1992) Thin Solid Films, 214:156

Zabinski J.S., Donley M.S., McDevitt N.T. (1993) Wear 165:103

Stupp B.C.. (1981) Thin Solid Films 84:257

Spalvins T., (1984) Thin Solid Films 118:375

Hilton M.R., Bauer R., Didziulis S.V., Dugger M.T., Keem J.M., Scholhamer J.. (1992) Surf. Coat. Technol. 53:13

Wahl K.J., Seitzman L.E., Bolster R.N., Singer I.L. (1995) Surf. Coat. Technol. 73:152

Zabinski J.S., Donley M.S., Walck S.D., Schneider T.R., McDevitt N.T.. (1995) Tribol. Trans. 38 894

Teer D.G., Hampshire J., Fox V., Bellido-Gonzalez V.. (1997) Surf. Coat. Technol.. 94–95:572

A.A. Voevodin and J.S. Zabinski, in: Nanostructured Thin Films and Nanodispersion Strengthened Coatings, A.A. Voevodin, D.V. Shtansky, E.A. Levashov and J.J. Moore, eds. (Kluwer Academic Publishers, Dordrecht, Netherlands, 2004), pp. 1–8

A.R. Lansdown, in: Molybdenum Disulphide Lubrication, D. Dowson, ed. (Elsevier, Amsterdam, 1999)

F.G. Fisher, A.D. Cron, R.G. Muber, NGLI Spokesman, Vol. 46 (National Lubricating Grease Institute, 1982), p. 190

Gardos M.N. (1988) Tribol. Trans. 31:214

Buck V. (1983) Wear 91:281

Moser J., Levy F.. (1993) Thin Solid Films 228:257

Savage R.H.. (1948) J. Appl. Phys. 19:1

M.N. Gardos, in: Proceedings of 1st Tribology Congress on New Directions in Tribology, London, 8–12 September 1997, Institute of Mechanical engineers, London (1997), Paper 229

Fleischauer P.D., Lince J.R., Bertrand P.A., Bauer R.. (1989) Langmuir 5:1009

Fleischauer P.D., Lince J.R.. (1999) Tribol. Int. 32:627

Acknowledgement

The Air Force Office of Scientific Research (AFOSR) is gratefully acknowledged for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zabinski, J., Bultman, J., Sanders, J. et al. Multi-environmental lubrication performance and lubrication mechanism of MoS2/Sb2O3/C composite films. Tribol Lett 23, 155–163 (2006). https://doi.org/10.1007/s11249-006-9057-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-006-9057-0