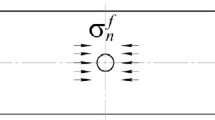

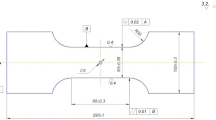

The fatigue life prediction method for structure elements with the material precompression in the hole vicinity is proposed. The method is a further step in evolving the approach to life prediction from a local stress-strain state that is based on the energy criterion of fatigue fracture. Residual stresses arising from the material compression in the hole vicinity were evaluated by the finite element method. The problem of contact interaction of the punch profile with corresponding specimen portions was solved in the physically nonlinear statement. The nonlinear behavior of the hole-containing strip material under elastoplastic deformation was simulated with the multilinear model, including kinematic hardening. In life calculations, residual compression stresses were accounted for by introducing additional fictitious ones into the load cycle. The variation of fatigue material characteristics under asymmetric loading were considered by introducing the additional function derived from the test results for smooth specimens under symmetrical loading. Computational results were compared with fatigue test data. For this, D16AT and V95pchT2 aluminum alloy flat specimens with material precompression in the hole vicinity were tested under regular and program loading. Regular loading was realized by a zero-to-tension stress cycle, the program one was effected witch the stepped program equivalent to the damage during the combined operation of a multi-purpose aircraft. Satisfactory agreement between calculation data and experimental results was noted.

Similar content being viewed by others

References

E. A. Shakhatuni and F. M. Lyubarets, “Increase in durability of aircraft structures by compression around cylindrical belt-shaped punche holes,” Aviats. Promyshl., No. 9, 12–13 (1977).

A. G. Grebenikov, G. A. Krivov, E. T. Vasilevskii, et al., “Experimental study on the effect of successive application of mandrelling and barrier compression on the fatigue life of stringers in the vicinity of fuel flow openings,” in: Open Information and Computer Integrated Technologies [in Russian], Issue 43 (2009), pp. 54–64.

V. P. Rychik, A. E. Litvinenko, N. T. Ostapenko, et al., “Studies on the durability of lower wing panels with fuel flow openings,” in: Proc. of the Conf. on Durability and Life of Aircraft Structures [in Russian] (1976), pp. 100–103.

A. Z. Vorob’ev, B. I. Ol’kin, V. N. Stebenev, et al., Fatigue Resistance of Structure Elements [in Russian], Mashinostroenie, Moscow (1990).

A. A. Serdyuk, S. P. Krapivin, A. O. Reidman, et al., “Opening hardening techniques with local deep plastic deformation,” Aviats. Promyshl., No. 8, 8–11 (1983).

A. V. Zarutskii. “Experimental investigation of the durability of specimens with hardened holes. Part 1. Regular loading,” in: Problems of Design and Manufacture of Flying Vehicle Structures [in Russian], Issue 1 (77) (2014), pp. 29–35.

A. V. Zarutskii, “Experimental investigation of the durability of specimens with hardened holes. Part 2. Program loading,” in: Problems of Design and Manufacture of Flying Vehicle Structures [in Russian], Issue 2 (78) (2014), pp. 57–65.

P. A. Fomichev, “Substantiation of the predicted fatigue curve for structure elements of aluminum alloy,” Strength Mater., 43, No. 4, 363–373 (2011).

ANSYS Analysis Guide. Structural Analysis Guide. Ch. 8. Nonlinear Structural Analysis, 001087, 4th Edition, SAS IP@.

V. E. Strizhius, “Fatigue calculation methods for aircraft structure elements under multiaxial loading,” Nauch. Vestn. MGTU GA, No. 187, 65–74 (2012).

P. A. Fomichev and A. V. Zarutskii, “Durability of specimens with hardened holes under regular loading,”in: Fracture Mechanics of Materials and Structural Strength (Proc. of the 5th Int. Conf., June 24–27, 2014, Lvov) (2014), pp. 278–282.

V. T. Troshchenko and P. A. Fomichev, “An energy criterion for fatigue failure,” Strength Mater., 25, No. 1, 1–7 (1993).

P. A. Fomichev, “Energy method of calculating longevity under an irregular loading. Report 1. Consideration of loading sequence,” Strength Mater., 27, No. 7, 355–362 (1995).

P. A. Fomichev, “Energy method of longevity calculation under an irregular loading. Report 2. Longevity under programmed block loading,” Strength Mater., 27, No. 8, 427–433 (1995).

P. A. Fomichev, “Consideration of mean stresses in the life assessment method by a local stress-strain state,” in: Fracture Mechanics of Materials and Structural Strength (Proc. of the 5th Conf., June 24–27, 2014, Lvov) (2014), pp. 731–736.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 2, pp. 26 – 35, March – April, 2019.

Rights and permissions

About this article

Cite this article

Fomichev, P.A., Zarutskii, A.V. Fatigue Life Prediction by a Local Stress-Strain Criterion for Hole-Containing Specimens After Precompression of Their Material. Strength Mater 51, 193–201 (2019). https://doi.org/10.1007/s11223-019-00065-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-019-00065-w