Abstract

The acidity of Zr-incorporated large pore cubic mesoporous silicate, KIT-5, with Fm3m symmetry was explored as catalyst in the Hantzsch reaction for preparation of 1,4-dihydropyridine (DHP) derivatives, Meerwein–Ponndorf–Verley (MPV) reduction of 4-tert-butylcyclohexanone, and Prins reaction of citronellal. The catalyst showed ~82–94 % selectivity for formation of DHP derivatives based on substituted benzaldehydes. For the intramolecular cyclization of citronellal, the activity and isomer selectivity increased with Zr content. Both these reactions proceeded to nearly total conversion in relatively short reaction times of 3 h and 30 min, respectively. In sharp contrast, MPV reduction of 4-tert-butylcyclohexanone yielded 95 % conversion in 4 days, similar to those reported for Zr-TUD-1.

Similar content being viewed by others

Introduction

Zirconium-containing mesoporous silica composites have been investigated as solid acid catalysts based on the presence of Lewis acid sites created by Zr4+ incorporation in the framework and the large surface area, pore volume, and uniform pore size distribution [1–4]. Since the discovery of mesoporous silicates such as MCM-41 and SBA-15, two- and three-dimensional mesostructured silica materials containing Zr have been synthesized including Zr-MCM-41 [5, 6], Zr-MCM-48 [7, 8], Zr-SBA-15 [1, 3, 9], and Zr-SBA-16 [10]. Recently, Zr-containing ordered cubic mesoporous silicates such as Zr-KIT-6 [11] and Zr-KIT-5 [12] have also been synthesized and shown to be active for acid catalyzed reactions such as dehydration of isopropanol [13], ethanol [14], and Friedel–Crafts benzylation of anisole [12]. In particular, it was demonstrated that Zr-KIT-5 catalysts are stable and recyclable following liquid phase reactions at temperatures up to 170 °C [12]. Based on these advantages, we investigate in this work if the Lewis acidic Zr-KIT-5 materials may be used as promising and alternative green solid acid catalysts for reactions such as the synthesis of DHP derivatives (Hantzsch reaction), Prins reaction of citronellal, and Meerwein–Ponndorf–Verley (MPV) reduction of 4-tert-butylcyclohexanone.

Experimental

Synthesis and characterization of Zr-KIT-5

The detailed procedure for synthesis of Zr-KIT-5 and their characterization may be found in our recent publication [12]. Briefly, Pluronic F127 (1.8 g) was dissolved in 0.4 M HCl (90 mL) at 45 °C followed by addition of tetraethylorthosilicate (8.5 g) and of required amounts ZrOCl2·8H2O and the mixture was stirred at the same temperature for 24 h. After that, they were hydrothermally treated in a Teflon lined autoclave at 100 °C for a period of another 24 h. Final Zr-KIT-5 samples were obtained after filtration and calcination at 550 °C to remove the template.

Small angle X-ray scattering SAXS (2θ = 0.5°–2.5°) and powder XRD (2θ = 10°–80°) patterns were recorded on a S-MAX 3000 instrument and Rigaku MiniFlex diffractometer respectively with Cu-Kα radiation (λ = 0.1548 nm). Nitrogen adsorption–desorption isotherms were measured at −196 °C on a Quantachrome NOVA 2000e sorption analyzer. Diffuse reflectance UV–Vis spectra were recorded with a Perkin Elmer Lambda 850 spectrometer equipped with diffuse reflectance integrating sphere, with Spectralon as the reference. Elemental analysis was performed on a Horiba Jobin–Yvon JY 2000 (ICP-OES) instrument after digesting the catalyst samples in a HF and H2SO4 mixture. Acidity measurement was carried out by temperature programmed desorption of ammonia (NH3-TPD) spectra on a Micromeritics Autochem 2910 instrument equipped with a thermal conductivity detector (TCD). Data obtained via these techniques are fully described in Ref. [12].

Catalytic activity

For the Hantzsch reaction, freshly distilled benzaldehyde (1 mmol), ethyl acetoacetate (2 mmol), ammonium acetate (1.2 mmol), and 4 mL of ethanol (solvent) were added to a 25-mL, two-neck, round-bottom flask equipped with a condenser and magnetic stir bar. Then Zr-KIT-5 (Si/Zr ratio = 25, containing 0.06 mmol Zr), was charged to the reaction mixture and the reaction was started by immersing the flask into a preheated oil bath at 80 °C. The reaction was monitored periodically by TLC (monitored using hexane:ethyl acetate 7:3). After completion of the reaction, the resultant mixture was cooled down to room temperature, filtered (to separate the catalyst), and the filtrate was added to cold water; the formed precipitate was filtered off. The crude product was further purified by recrystallization using ethanol. The isolated pure compound was confirmed by 1H NMR, 13C NMR and FT-IR and also by comparison with the literature reports [15, 16]. Representative characterization data are also provided in supplementary information.

For the Prins cyclisation of citronellal, the following general protocol was applied (method reported earlier [2, 17]). In a Schlenk flask of 50 mL (placed in an oven at 70 °C overnight), 50 mg of catalyst (activated in an oven overnight at 100 °C) were introduced. After flushing the vapour space with N2, 5 g of dry toluene were introduced followed by 0.1 mL of tri-isopropylbenzene (IS) and then finally 4 mmol of ±citronellal (industrial grade, containing approx. 5 % isopulegol, 0.725 mL). The mixture was then placed in an oil bath at 80 °C and stirred under N2. Samples were regularly withdrawn using a capillary tube (introduced in the reaction medium via a needle), filtered over a cotton plug (in a Pasteur pipette), diluted, and analyzed by GC.

GC method: Column: Cyclodex-B; Detector temperature: 270 °C; Injector temperature: 250 °C; Temp. gradient: beginning at 140 °C hold for 16.0 min, then increased by 50 °C min−1 to 250 °C (hold 1 min); Column flow: 0.87 mL min−1 (linear velocity 20.3 cm s−1); Split ratio: 50; Total time: 19.20 min. Retention times: ±citronellal: 12.67 min, isopulegol: 13.45, neo-isopulegol: 13.62 min, iso-isopulegol: 14.77 min, neoiso-isopulegol: 14.90 min, internal standard (IS): 17.03 min.

For the catalyst recycling runs, the reaction was carried out as described above (but first step with ×4 quantities: 200 mg catalyst, 20 g of dry toluene, 0.4 mL IS and 16 mmol citronellal). The catalysts were recycled after filtration and calcination (600 °C, 6 h) and used again in a new reaction following the same protocol.

For the hot filtration test, the reaction was started as described above. After 10 min the reaction medium is sampled via a dried syringe and immediately filtered through a PTFE syringe filter previously washed with anhydrous toluene at 80 °C. The liquid medium is introduced directly into a Schlenk flask of 50 mL, previously placed overnight in an oven at 70 °C, flushed with N2, and left at 80 °C. The monitoring of the reaction was done before and after filtration following the same protocol as described before.

For the Meerwein-Ponndorf-Verley reduction of 4-tert-butylcyclohexanone, the following general protocol was applied (method reported earlier [2, 17]). In a Schlenk flask of 50 mL (placed in an oven at 70 °C overnight), 50 mg of catalyst (freshly calcined) was introduced followed by 2 mmol of 4-tert-butylcyclohexanone (308.5 mg). After flushing the vapour phase with N2, 4 mL of isopropanol and 0.1 mL of triisopropylbenzene (IS) were added. The mixture was then placed in an oil bath at 80 °C and stirred under N2 for several days. Samples were regularly withdrawn using a capillary tube (introduced in the reaction medium via a needle), filtered over a cotton plug (in a Pasteur pipette), diluted, and analyzed by GC.

GC method: Column: Cyclodex-B; Detector temperature: 270 °C; Injector temperature: 250 °C; Temp. gradient: beginning at 150 °C hold for 14.0 min, then increased at 50 °C min−1 to 250 °C (hold 1 min); Column flow: 1.50 mL min−1 (linear velocity 29.5 cm s−1); Split ratio: 50; Total time: 17.03 min. Retention times: 4-tert-butylcyclohexanone: 11.3 min, 4-tert-butylcyclohexanol: 9.7 (cis) and 10.4 min (trans), IS: 10.2 min.

Results and discussions

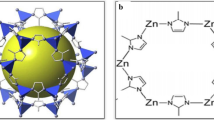

The relevant properties of Zr-KIT-5 catalysts are briefly summarized in Table 1. In general, Zr-KIT-5 materials presented high surface area (970–1020 m2 g−1), pore volume (0.7–0.8 cm3 g−1), and uniform pore size distribution with a cage diameter of 8.8 nm [12]. Also, the total acidity of Zr-KIT-5 increased with Zr loading and the predominant type of acidity is found to be a Lewis acid [12]. Representative TEM results are given in Fig. 1. The activity of Zr-KIT-5 at different temperatures and the effect of Si/Zr for the one pot synthesis of Dihydropyridine derivatives via Hantzsch reaction is given in Table 2. In an uncatalyzed reaction at 80 °C, even after 12 h, only 10 % of the expected product was obtained (Table 2, entry 6). On the other hand, adding catalytic amounts of Zr-KIT-5 under similar reaction conditions, a dramatic increase in the yield up to 85 % in a relatively short batch time of 3 h was observed. For a similar amount of catalyst and under identical reaction conditions, a higher yield of DHP was obtained over Zr-KIT-5 (25) (see Table 2, entries 1–3). This is clearly attributed to increase in number of acid sites which increases with decrease in Si/Zr ratio. Similarly, with increase in temperature from 40 to 80 °C, about 85 % DHP was yielded in a shorter reaction time of 3 h (see Table 2, entries 3–5).

Based on the substituents in the benzaldehydes and heterocyclic aldehydes, Zr-KIT-5 gave good yields with only minor variations in the final reaction time. The excellent activity of Zr-KIT-5 is further borne out by the fact that when the reaction is performed with homogeneous ZrOCl2 under similar reaction conditions, only 47 % product yield is obtained even with a threefold longer batch reaction duration (Table 3, entry 8).

Because of their demonstrated strong Lewis acidity, the Zr-KIT-5 catalysts are excellent candidates for reactions such as the Prins cyclization or the MPV reaction, as also shown previously with other mesoporous Zr silicates, Zr-TUD-1 [17]. These two reactions may lead to interesting applications such as the synthesis of menthol (in which the cyclization of citronellal is a first step) or the MPV reduction of steroids such as cholesterol [18, 19]. The Zr-KIT-5 samples were therefore tested for both reactions.

The intramolecular cyclization of citronellal leads to the formation of different isomers of isopulegol (Scheme 1). The observed activities and isomers selectivity on the tested Zr-KIT-5 catalysts were excellent (Table 4; Fig. 2), increasing with the amount of incorporated Zr. These results were obtained with industrial grade citronellal containing around 5 % isopulegol which is known to inhibit the reaction, thus higher activities can be expected starting from optically pure citronellal [2]. These results are quite similar to those reported with Zr-TUD-1 catalysts [2] and far higher than those reported with other zeolite catalysts [20].

a Temporal evolution of isopulegol and b variation of turnover frequencies (TOFs) during Prins cyclization on Zr-KIT-5 materials: 50 mg of catalyst in 5 g of dry toluene followed by 0.1 mL of tri-isopropylbenzene (IS) and then 4 mmol of ±citronellal (industrial grade, containing approx. 5 % isopulegol, 0.725 mL). Stirred at 80 °C under N2

Up to 95 % conversion in only 30 min (Table 4) was obtained using Zr-KIT-5 (25) as catalyst, which is quite similar to the conversion obtained with Zr-TUD-1 previously described [2]. The Zr-KIT-5 (50) and Zr-KIT-5 (100) samples show lower activity (92 % conversion in 50 min and 90 % conversion in 165 min, respectively). However, the turnover frequency, TOF, of Zr-KIT-5 (50) appeared higher than Zr-KIT-5 (25), suggesting an actual higher activity per active site (Table 4; Fig. 2b). However, this does not hold true for Zr-KIT-5 (100), which yields lower TOF values throughout the reaction (Fig. 2b). This observation, as well as the slower uptake observed at the beginning of the reaction, especially for Zr-KIT-5 (100), may suggest pore diffusion limitations.

The end-of run selectivity to isopulegol, as well as the observed diastereoselectivity for isopulegol, was around 75/25 for all Zr-KIT-5 catalysts (Table 4). These values are much higher than those for Zr-TUD-1 (around 65/35) [2]. This ratio is not affected by the amount of Zr incorporated. Unlike Zr-TUD-1 that has wide pores, Zr-KIT-5 has two types of pores, narrow gates (2.4–3.7 nm) interconnecting cages of 8.8 nm diameter. The narrow gates induce the higher diastereoselectivity in the reaction compared to Zr-TUD-1. At the same time, they might also cause pore diffusion limitations observed for Zr-KIT-5 (100). This is absent in Zr-TUD-1 (100).

Catalyst recycling experiments revealed that the Zr-KIT-5 materials could be recycled successfully during three consecutive attempts (Fig. 3a) with very little loss of the activity (>5 %). Moreover, a hot filtration test (filtration carried out at 80 °C to prevent any possible precipitation of soluble compounds, Fig. 3b) showed that the reaction is completely stopped after removal of the catalyst, proving the heterogeneous nature of the catalysis and the absence of leaching.

a Recycle experiments with Zr-KIT-5 (25) samples with calcination of the material following each cycle (“Experimental” conditions noted in Table 4); b Hot filtration test with Zr-KIT-5 (25), filtering off the catalyst at 80 ˚C after 10 min

The Zr-KIT-5 materials were also tested as catalysts in the MPV reduction of 4-tert-butylcyclohexanone (Scheme 2).

Zr-KIT-5 catalysts displayed moderate to high activity, depending on the amount of incorporated Zr (Fig. 4). The Zr-KIT-5 (25) with the highest Zr loading (and hence acidity) provided 95 % conversion in 4 days, similar to those reported with Zr-TUD-1 catalysts [2]. The activity decreases with the zirconium loading and the acidity of the material, as also observed for the Prins reaction. With the Zr-KIT-5 (50) and (100) catalysts, a conversion of 67 and 55 %, respectively, was observed in 3 days (Table 5). Furthermore, the observed product selectivity is excellent. The stereoselectivity is also high, up to a trans/cis ratio of 7/1 and comparable to literature values (around 6/1 for Zr-TUD-1 [2, 15]). This ratio increases slightly with the amount of Zr incorporated. This might again reflect the influence of the steric hindrance of the gate pores on the diastereoselelctivity. A much more extreme form of this was reported earlier [21].

a Evolution of the yield of 4-tert-butylcyclohexanol formed during the Meerwein–Ponndorf–Verley reduction catalysed by various Zr-KIT-5 materials and b turn over frequencies, TOF (50 mg of catalyst, 2 mmol of 4-tert-butylcyclohexanone (308.5 mg), 4 mL of isopropanol, and 0.1 mL of tri-isopropylbenzene (IS) were placed in an oil bath at 80 °C and stirred under N2)

Conclusions

The Lewis acidity in Zr-KIT-5 samples stemming from Zr4+ incorporation is shown to catalyze three reactions efficiently. The general acid catalysed Hantzsch reaction and two Lewis acid catalysed reactions; the Meerwein–Ponndorf–Verley reduction of 4-tert-butylcyclohexanone and the Prins reaction of citronellal. Excellent reactivity, selectivity and stereoselectivity, that are tuned with catalyst acidity (i.e., Zr loading), are observed for both reactions. Excellent catalyst recyclability was also observed confirming that Zr-KIT-5 catalysts are catalysts with high potential.

References

D.M. Do, S. Jaenicke, G.-K. Chuah, Catal. Sci. Technol. 2, 1417 (2012)

A. Ramanathan, M.C. Castro Villalobos, C. Kwakernaak, S. Telalovic, U. Hanefeld, Chem. Eur. J. 14, 961 (2008)

J.A. Melero, L.F. Bautista, J. Iglesias, G. Morales, R. Sánchez-Vázquez, Catal. Biorefin. 195, 44 (2012)

S.-Y. Chen, J.-F. Lee, S. Cheng, J. Catal. 270, 196 (2010)

X.X. Wang, F. Lefebvre, J. Patarin, J.-M. Basset, Microporous Mesoporous Mater. 42, 269 (2001)

M. Occelli, S. Biz, A. Auroux, Appl. Catal. Gen. 183, 231 (1999)

M.S. Morey, G.D. Stucky, S. Schwarz, M. Froba, J. Phys. Chem. B 103, 2037 (1999)

L.F. Chen, X.L. Zhou, L.E. Noreña, J.A. Wang, J. Navarrete, P. Salas, A. Montoya, P. Del Angel, M.E. Llanos, Appl. Surf. Sci. 253, 2443 (2006)

W.-K. Chen, H.-H. Tseng, M.-C. Wei, E.-C. Su, I.-C. Chiu, Int. J. Hydrog. Energy 39, 19555 (2014)

N. Jiang, J.-B. Koo, S.-C. Han, S.-E. Park, Res. Chem. Intermed. 34, 507 (2008)

A. Ramanathan, B. Subramaniam, R. Maheswari, U. Hanefeld, Microporous Mesoporous Mater. 167, 207 (2013)

A. Ramanathan, H. Zhu, R. Maheswari, B. Subramaniam, Chem. Eng. J. 278, 113 (2015)

Q. Pan, A. Ramanathan, W.K. Snavely, R.V. Chaudhari, B. Subramaniam, Ind. Eng. Chem. Res. 52, 15481 (2013)

Q. Pan, A. Ramanathan, W.K. Snavely, R. Chaudhari, B. Subramaniam, Top. Catal. 57, 1407 (2014)

A. Debache, W. Ghalem, R. Boulcina, A. Belfaitah, S. Rhouati, B. Carboni, Tetrahedron Lett. 50, 5248 (2009)

C.A. Antonyraj, S. Kannan, Appl. Catal. Gen. 338, 121 (2008)

S. Telalović, A. Ramanathan, J.F. Ng, R. Maheswari, C. Kwakernaak, F. Soulimani, H.C. Brouwer, G.K. Chuah, B.M. Weckhuysen, U. Hanefeld, Chem. Eur. J. 17, 2077 (2011)

A. Ramanathan, D. Klomp, J.A. Peters, U. Hanefeld, J. Mol. Catal. Chem. 260, 62 (2006)

D. Klomp, K. Djanashvili, N.C. Svennum, N. Chantapariyavat, C.-S. Wong, F. Vilela, T. Maschmeyer, J.A. Peters, U. Hanefeld, Org. Biomol. Chem. 3, 483 (2005)

Z. Yongzhong, N. Yuntong, S. Jaenicke, G.-K. Chuah, J. Catal. 229, 404 (2005)

E. Creyghton, S. Ganeshie, R. Downing, H. van Bekkum, J. Mol. Catal. Chem. 115, 457 (1997)

P.P. Ghosh, S. Paul, A.R. Das, Tetrahedron Lett. 54, 138 (2013)

A. Heydari, S. Khaksar, M. Tajbakhsh, H.R. Bijanzadeh, J. Fluor. Chem. 130, 609 (2009)

Acknowledgments

The authors acknowledge financial support for this work by the US Department of Agriculture and the National Institute of Food and Agriculture through Grant No. 2011-10006-30362.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Vinju Vasudevan Srinivasan and Adeline Ranoux have contributed equally to the present work.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Srinivasan, V.V., Ranoux, A., Maheswari, R. et al. Potential applications of Zr-KIT-5: Hantzsch reaction, Meerwein–Ponndorf–Verley (MPV) reduction of 4-tert-butylcyclohexanone, and Prins reaction of citronellal. Res Chem Intermed 42, 2399–2408 (2016). https://doi.org/10.1007/s11164-015-2157-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-015-2157-4